jul-aug2012

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Flight Safety Australia<br />

Issue 87 July–August 2012<br />

31<br />

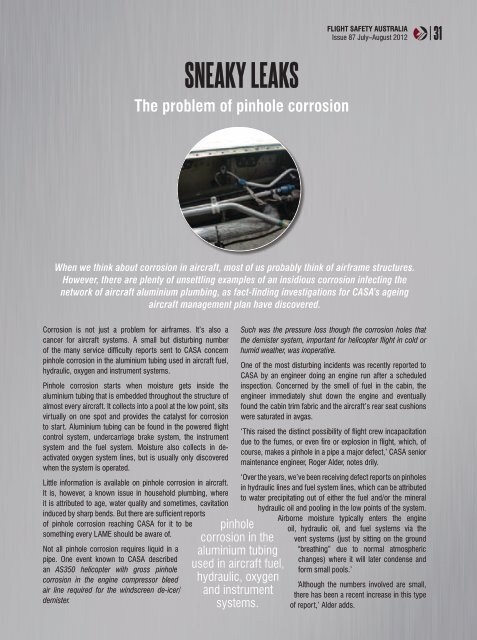

Sneaky leaks<br />

The problem of pinhole corrosion<br />

When we think about corrosion in aircraft, most of us probably think of airframe structures.<br />

However, there are plenty of unsettling examples of an insidious corrosion infecting the<br />

network of aircraft aluminium plumbing, as fact-finding investigations for CASA’s ageing<br />

aircraft management plan have discovered.<br />

Corrosion is not just a problem for airframes. It’s also a<br />

cancer for aircraft systems. A small but disturbing number<br />

of the many service difficulty reports sent to CASA concern<br />

pinhole corrosion in the aluminium tubing used in aircraft fuel,<br />

hydraulic, oxygen and instrument systems.<br />

Pinhole corrosion starts when moisture gets inside the<br />

aluminium tubing that is embedded throughout the structure of<br />

almost every aircraft. It collects into a pool at the low point, sits<br />

virtually on one spot and provides the catalyst for corrosion<br />

to start. Aluminium tubing can be found in the powered flight<br />

control system, undercarriage brake system, the instrument<br />

system and the fuel system. Moisture also collects in deactivated<br />

oxygen system lines, but is usually only discovered<br />

when the system is operated.<br />

Little information is available on pinhole corrosion in aircraft.<br />

It is, however, a known issue in household plumbing, where<br />

it is attributed to age, water quality and sometimes, cavitation<br />

induced by sharp bends. But there are sufficient reports<br />

of pinhole corrosion reaching CASA for it to be<br />

something every LAME should be aware of.<br />

Not all pinhole corrosion requires liquid in a<br />

pipe. One event known to CASA described<br />

an AS350 helicopter with gross pinhole<br />

corrosion in the engine compressor bleed<br />

air line required for the windscreen de-icer/<br />

demister.<br />

pinhole<br />

corrosion in the<br />

aluminium tubing<br />

used in aircraft fuel,<br />

hydraulic, oxygen<br />

and instrument<br />

systems.<br />

Such was the pressure loss though the corrosion holes that<br />

the demister system, important for helicopter flight in cold or<br />

humid weather, was inoperative.<br />

One of the most disturbing incidents was recently reported to<br />

CASA by an engineer doing an engine run after a scheduled<br />

inspection. Concerned by the smell of fuel in the cabin, the<br />

engineer immediately shut down the engine and eventually<br />

found the cabin trim fabric and the aircraft’s rear seat cushions<br />

were saturated in avgas.<br />

‘This raised the distinct possibility of flight crew incapacitation<br />

due to the fumes, or even fire or explosion in flight, which, of<br />

course, makes a pinhole in a pipe a major defect,’ CASA senior<br />

maintenance engineer, Roger Alder, notes drily.<br />

‘Over the years, we’ve been receiving defect reports on pinholes<br />

in hydraulic lines and fuel system lines, which can be attributed<br />

to water precipitating out of either the fuel and/or the mineral<br />

hydraulic oil and pooling in the low points of the system.<br />

Airborne moisture typically enters the engine<br />

oil, hydraulic oil, and fuel systems via the<br />

vent systems (just by sitting on the ground<br />

“breathing” due to normal atmospheric<br />

changes) where it will later condense and<br />

form small pools.’<br />

‘Although the numbers involved are small,<br />

there has been a recent increase in this type<br />

of report,’ Alder adds.