Template for HA Research Notes - ISRA VISION AG

Template for HA Research Notes - ISRA VISION AG

Template for HA Research Notes - ISRA VISION AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ISRA</strong> Vision<br />

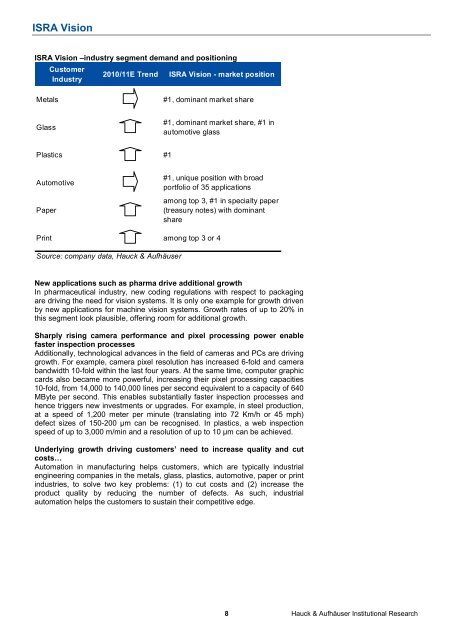

<strong>ISRA</strong> Vision –industry segment demand and positioning<br />

Customer<br />

Industry<br />

2010/11E Trend <strong>ISRA</strong> Vision - market position<br />

Metals #1, dominant market share<br />

Glass<br />

Plastics #1<br />

Automotive<br />

Paper<br />

#1, dominant market share, #1 in<br />

automotive glass<br />

#1, unique position with broad<br />

portfolio of 35 applications<br />

among top 3, #1 in specialty paper<br />

(treasury notes) with dominant<br />

share<br />

Print among top 3 or 4<br />

Source: company data, Hauck & Aufhäuser<br />

New applications such as pharma drive additional growth<br />

In pharmaceutical industry, new coding regulations with respect to packaging<br />

are driving the need <strong>for</strong> vision systems. It is only one example <strong>for</strong> growth driven<br />

by new applications <strong>for</strong> machine vision systems. Growth rates of up to 20% in<br />

this segment look plausible, offering room <strong>for</strong> additional growth.<br />

Sharply rising camera per<strong>for</strong>mance and pixel processing power enable<br />

faster inspection processes<br />

Additionally, technological advances in the field of cameras and PCs are driving<br />

growth. For example, camera pixel resolution has increased 6-fold and camera<br />

bandwidth 10-fold within the last four years. At the same time, computer graphic<br />

cards also became more powerful, increasing their pixel processing capacities<br />

10-fold, from 14,000 to 140,000 lines per second equivalent to a capacity of 640<br />

MByte per second. This enables substantially faster inspection processes and<br />

hence triggers new investments or upgrades. For example, in steel production,<br />

at a speed of 1,200 meter per minute (translating into 72 Km/h or 45 mph)<br />

defect sizes of 150-200 µm can be recognised. In plastics, a web inspection<br />

speed of up to 3,000 m/min and a resolution of up to 10 µm can be achieved.<br />

Underlying growth driving customers’ need to increase quality and cut<br />

costsM<br />

Automation in manufacturing helps customers, which are typically industrial<br />

engineering companies in the metals, glass, plastics, automotive, paper or print<br />

industries, to solve two key problems: (1) to cut costs and (2) increase the<br />

product quality by reducing the number of defects. As such, industrial<br />

automation helps the customers to sustain their competitive edge.<br />

8 Hauck & Aufhäuser Institutional <strong>Research</strong>