SUMMER 2016

Distributor's Link Magazine Summer Issue 2016 / Vol 39 No3

Distributor's Link Magazine Summer Issue 2016 / Vol 39 No3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8<br />

THE DISTRIBUTOR’S LINK<br />

Bengt Blendulf<br />

Bengt Blendulf was educated in Sweden and moved to the US in 1974 to start a subsidiary for a Swedish fastener<br />

manufacturer. After working as a technical consultant on the faculty of the College of Engineering and Science at<br />

Clemson University, he established EduPro US in 1997 to teach highly rated courses in Fastening Technology in the US,<br />

Canada, Mexico, Europe and Asia. Being one of the founders, Bengt served as the chairman of ASTM F16.96 Bolting<br />

Technology from 1996 to 2006. In 2006 he received the Fred F. Weingruber award from ASTM for “his efforts to promote<br />

and develop standards for the fastener industry.” In 2013 he also received IFI’s Soaring Eagle Award for “significant<br />

contributions to the technological advancement of the fastener industry”. Bengt is the author of an extensive lecture book,<br />

well over 110 articles and “Mechanical Fastening and Joining”, a book published in 2013 by the Industrial Fasteners<br />

Institute. He can be contacted through www.edupro.us or by email bblendulf@yahoo.com.<br />

BIGGER BOLTS OR SMALLER BOLTS?<br />

An American company was faced with a joint problem.<br />

The assembly had some weaknesses they had a problem<br />

to rectify. It looked like a relatively simple case with a<br />

square end plate being bolted onto a machine part with<br />

four ½” Grade 5 bolts. The external load was applied with a<br />

somewhat irregular fashion and had caused some loosening<br />

of the fasteners. This had eventually caused fastener failures<br />

due to fatigue problems. They did request assistance in fixing<br />

the problem and, at the same time, also to make a quick<br />

conversion to metric since the product was going overseas.<br />

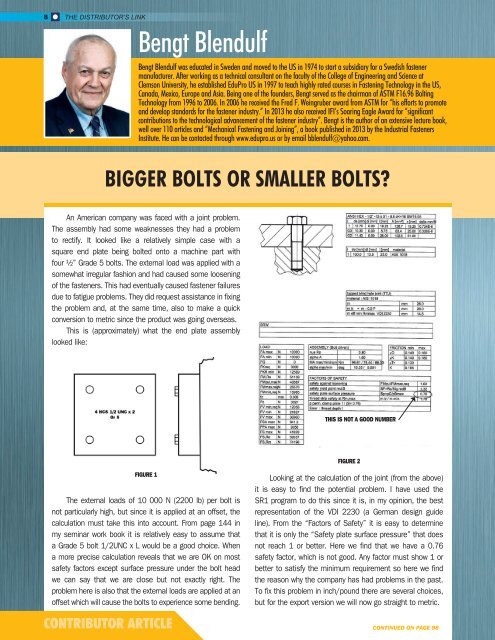

This is (approximately) what the end plate assembly<br />

looked like:<br />

THIS IS NOT A GOOD NUMBER<br />

FIGURE 2<br />

FIGURE 1<br />

The external loads of 10 000 N (2200 lb) per bolt is<br />

not particularly high, but since it is applied at an offset, the<br />

calculation must take this into account. From page 144 in<br />

my seminar work book it is relatively easy to assume that<br />

a Grade 5 bolt 1/2UNC x L would be a good choice. When<br />

a more precise calculation reveals that we are OK on most<br />

safety factors except surface pressure under the bolt head<br />

we can say that we are close but not exactly right. The<br />

problem here is also that the external loads are applied at an<br />

offset which will cause the bolts to experience some bending.<br />

CONTRIBUTOR ARTICLE<br />

Looking at the calculation of the joint (from the above)<br />

it is easy to find the potential problem. I have used the<br />

SR1 program to do this since it is, in my opinion, the best<br />

representation of the VDI 2230 (a German design guide<br />

line). From the “Factors of Safety” it is easy to determine<br />

that it is only the “Safety plate surface pressure” that does<br />

not reach 1 or better. Here we find that we have a 0.76<br />

safety factor, which is not good. Any factor must show 1 or<br />

better to satisfy the minimum requirement so here we find<br />

the reason why the company has had problems in the past.<br />

To fix this problem in inch/pound there are several choices,<br />

but for the export version we will now go straight to metric.<br />

CONTINUED ON PAGE 98