SUMMER 2016

Distributor's Link Magazine Summer Issue 2016 / Vol 39 No3

Distributor's Link Magazine Summer Issue 2016 / Vol 39 No3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

44<br />

THE DISTRIBUTOR’S LINK<br />

CROSSROAD DISTRIBUTOR SOURCE<br />

Noblesville, IN | Dallas, TX | Chino, CA | Mississauqa, ONT Canada<br />

TEL 317-723-5050 FAX 317-723-5052 EMAIL sales@crossroad.bz WEB www.crossroad.bz<br />

REVOLUTIONARY THREAD REPAIR TECHNOLOGY<br />

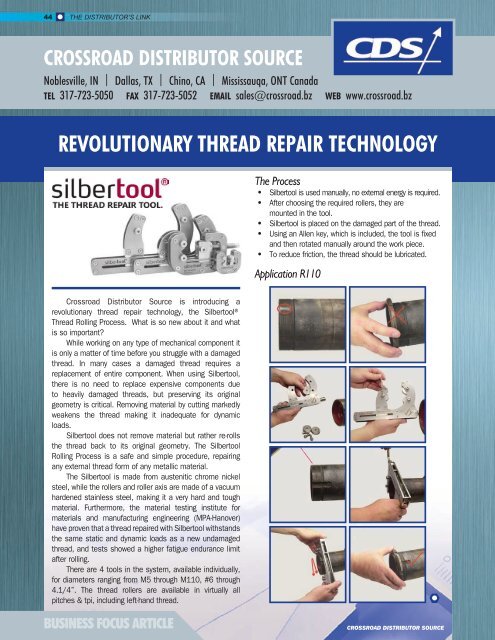

The Process<br />

• •<br />

•<br />

Silbertool is used manually, no external energy is required.<br />

After choosing the required rollers, they are<br />

mounted in the tool.<br />

Silbertool is placed on the damaged part of the thread.<br />

Using an Allen key, which is included, the tool is fixed<br />

and then rotated manually around the work piece.<br />

To reduce friction, the thread should be lubricated.<br />

Application R110<br />

Crossroad Distributor Source is introducing a<br />

revolutionary thread repair technology, the Silbertool®<br />

Thread Rolling Process. What is so new about it and what<br />

is so important?<br />

While working on any type of mechanical component it<br />

is only a matter of time before you struggle with a damaged<br />

thread. In many cases a damaged thread requires a<br />

replacement of entire component. When using Silbertool,<br />

there is no need to replace expensive components due<br />

to heavily damaged threads, but preserving its original<br />

geometry is critical. Removing material by cutting markedly<br />

weakens the thread making it inadequate for dynamic<br />

loads.<br />

Silbertool does not remove material but rather re-rolls<br />

the thread back to its original geometry. The Silbertool<br />

Rolling Process is a safe and simple procedure, repairing<br />

any external thread form of any metallic material.<br />

The Silbertool is made from austenitic chrome nickel<br />

steel, while the rollers and roller axis are made of a vacuum<br />

hardened stainless steel, making it a very hard and tough<br />

material. Furthermore, the material testing institute for<br />

materials and manufacturing engineering (MPA-Hanover)<br />

have proven that a thread repaired with Silbertool withstands<br />

the same static and dynamic loads as a new undamaged<br />

thread, and tests showed a higher fatigue endurance limit<br />

after rolling.<br />

There are 4 tools in the system, available individually,<br />

for diameters ranging from M5 through M110, #6 through<br />

4.1/4”. The thread rollers are available in virtually all<br />

pitches & tpi, including left-hand thread.<br />

BUSINESS FOCUS ARTICLE<br />

CROSSROAD DISTRIBUTOR SOURCE