EN welding technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MIG/MAG shield gas <strong>welding</strong> equipment<br />

Qualität Made<br />

in Germany<br />

PRO-MIG synergie – longest duty cycle, easiest operation, best <strong>welding</strong> results and maximum<br />

reliability<br />

Arguments<br />

XXSmart, superordinate IWC control<br />

XXElectronic choke sync SDI for an even better<br />

ignition process<br />

XXSynergie operation DCC via integrated<br />

database with stored characteristic curves<br />

XXSpecial MIG soldering characteristic curves<br />

(230 AM)<br />

XXSpecial aluminium characteristic curves in<br />

addition with PRO-MIG 230-4 AM, 300-4 to<br />

450-4 WS<br />

XXAutomatic wire threading, current and gas<br />

free in rapid motion<br />

XXAutomatic feed<br />

XXAutomatic inching for reliable ignition<br />

XXHold function<br />

XXPermanent mains voltage monitoring for a<br />

stable arc<br />

XXAutomatic wire burn-back for constant wire<br />

end lengths and an individually configurable<br />

burn-back time<br />

XXCustomisable gas post-flow time<br />

XXSafety forced shutdown in 4-cycle operation<br />

to prevent undesirable wire uncoiling<br />

XXTemperature controlled fan and water pump<br />

with standby circuit for low noise emission<br />

XXThermal protection switch<br />

XX2 large steering and fixed rollers<br />

Equipment features:<br />

XXPowerful 2- or 4-roll wire feed; digitally<br />

controlled with real-time monitoring<br />

XXClear-cut control panel<br />

XXTwo easy-to-read digital displays with Hold<br />

function for <strong>welding</strong> voltage, <strong>welding</strong> current<br />

and weldable material thickness<br />

XXExcess temperature display<br />

XXWire spool easy to change<br />

XXWire feed roll change without tools<br />

XXErgonomic design, housing as per<br />

IP 23 for outdoor <strong>welding</strong>.<br />

XXEasily manoeuvrable thanks to robust chassis<br />

with large wheels<br />

Operating modes<br />

XX2-cycle operation<br />

XX4-cycle operation<br />

XXSpot <strong>welding</strong><br />

XXSynergie operation<br />

XXManual operation<br />

Configurable parameters<br />

XXSpot/interval time<br />

XXWelding output<br />

Method<br />

XXMIG/MAG<br />

XXMIG soldering (PRO-MIG 230 AM synergie)<br />

Sheet thicknesses<br />

XXfrom 0.5 mm (MAG)<br />

XXAluminium from 0.8 mm (MIG)<br />

XXMIG soldering as of 0.5 mm<br />

Base materials<br />

XXConstruction steels, non alloy and low alloy<br />

materials<br />

XXCrNi steels ferritic/austenitic<br />

XXDuplex steels<br />

XXAluminium (MIG)<br />

XXgalvanised, pre-treated steels (MIG<br />

soldering)<br />

Typical applications<br />

XXPlant, container, machine, steel construction<br />

XXMaintenance/repairs<br />

XXAutomobile industry and automotive supplies<br />

XXVehicle maintenance and repairs<br />

XXVehicle manufacturing/construction<br />

machinery<br />

XXRail vehicle manufacturing<br />

XXShipbuilding<br />

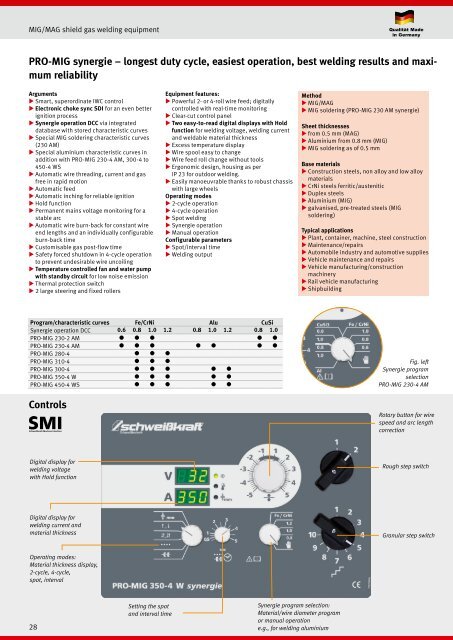

Program/characteristic curves Fe/CrNi Alu CuSi<br />

Synergie operation DCC 0.6 0.8 1.0 1.2 0.8 1.0 1.2 0.8 1.0<br />

PRO-MIG 230-2 AM<br />

PRO-MIG 230-4 AM<br />

PRO-MIG 280-4<br />

PRO-MIG 310-4<br />

PRO-MIG 300-4<br />

PRO-MIG 350-4 W<br />

PRO-MIG 450-4 WS<br />

Controls<br />

Fig. left<br />

Synergie program<br />

selection<br />

PRO-MIG 230-4 AM<br />

Rotary button for wire<br />

speed and arc length<br />

correction<br />

Digital display for<br />

<strong>welding</strong> voltage<br />

with Hold function<br />

Rough step switch<br />

Digital display for<br />

<strong>welding</strong> current and<br />

material thickness<br />

Granular step switch<br />

Operating modes:<br />

Material thickness display,<br />

2-cycle, 4-cycle,<br />

spot, interval<br />

28<br />

Setting the spot<br />

and interval time<br />

Synergie program selection:<br />

Material/wire diameter program<br />

or manual operation<br />

e.g., for <strong>welding</strong> aluminium