EN welding technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

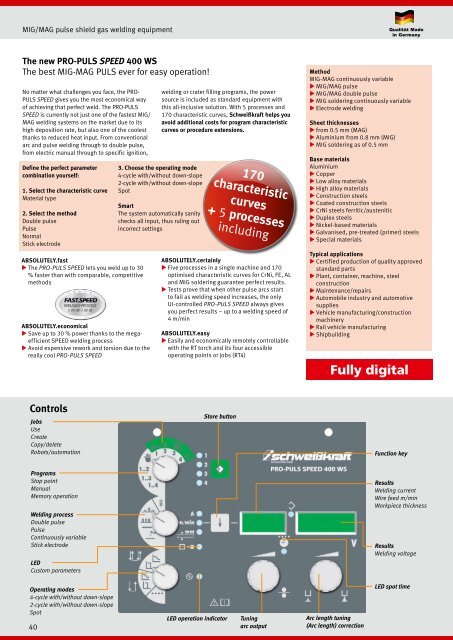

MIG/MAG pulse shield gas <strong>welding</strong> equipment<br />

Qualität Made<br />

in Germany<br />

The new PRO-PULS SPEED 400 WS<br />

The best MIG-MAG PULS ever for easy operation!<br />

No matter what challenges you face, the PRO-<br />

PULS SPEED gives you the most economical way<br />

of achieving that perfect weld. The PRO-PULS<br />

SPEED is currently not just one of the fastest MIG/<br />

MAG <strong>welding</strong> systems on the market due to its<br />

high deposition rate, but also one of the coolest<br />

thanks to reduced heat input. From conventional<br />

arc and pulse <strong>welding</strong> through to double pulse,<br />

from electric manual through to specific ignition,<br />

Define the perfect parameter<br />

combination yourself:<br />

1. Select the characteristic curve<br />

Material type<br />

2. Select the method<br />

Double pulse<br />

Pulse<br />

Normal<br />

Stick electrode<br />

ABSOLUTELY.fast<br />

XXThe PRO-PULS SPEED lets you weld up to 30<br />

% faster than with comparable, competitive<br />

methods<br />

ABSOLUTELY.economical<br />

XXSave up to 30 % power thanks to the megaefficient<br />

SPEED <strong>welding</strong> process<br />

XXAvoid expensive rework and torsion due to the<br />

really cool PRO-PULS SPEED<br />

<strong>welding</strong> or crater filling programs, the power<br />

source is included as standard equipment with<br />

this all-inclusive solution. With 5 processes and<br />

170 characteristic curves, Schweißkraft helps you<br />

avoid additional costs for program characteristic<br />

curves or procedure extensions.<br />

3. Choose the operating mode<br />

4-cycle with/without down-slope<br />

2-cycle with/without down-slope<br />

Spot<br />

Smart<br />

The system automatically sanity<br />

checks all input, thus ruling out<br />

incorrect settings<br />

170<br />

characteristic<br />

curves<br />

+ 5 processes<br />

including<br />

ABSOLUTELY.certainly<br />

XXFive processes in a single machine and 170<br />

optimised characteristic curves for CrNi, FE, AL<br />

and MIG soldering guarantee perfect results.<br />

XXTests prove that when other pulse arcs start<br />

to fail as <strong>welding</strong> speed increases, the only<br />

UI-controlled PRO-PULS SPEED always gives<br />

you perfect results – up to a <strong>welding</strong> speed of<br />

4 m/min<br />

ABSOLUTELY.easy<br />

XXEasily and economically remotely controllable<br />

with the RT torch and its four accessible<br />

operating points or jobs (RT4)<br />

Method<br />

MIG-MAG continuously variable<br />

XXMIG/MAG pulse<br />

XXMIG/MAG double pulse<br />

XXMIG soldering continuously variable<br />

XXElectrode <strong>welding</strong><br />

Sheet thicknesses<br />

XXfrom 0.5 mm (MAG)<br />

XXAluminium from 0.8 mm (MIG)<br />

XXMIG soldering as of 0.5 mm<br />

Base materials<br />

Aluminium<br />

XXCopper<br />

XXLow alloy materials<br />

XXHigh alloy materials<br />

XXConstruction steels<br />

XXCoated construction steels<br />

XXCrNi steels ferritic/austenitic<br />

XXDuplex steels<br />

XXNickel-based materials<br />

XXGalvanised, pre-treated (primer) steels<br />

XXSpecial materials<br />

Typical applications<br />

XXCertified production of quality approved<br />

standard parts<br />

XXPlant, container, machine, steel<br />

construction<br />

XXMaintenance/repairs<br />

XXAutomobile industry and automotive<br />

supplies<br />

XXVehicle manufacturing/construction<br />

machinery<br />

XXRail vehicle manufacturing<br />

XXShipbuilding<br />

Fully digital<br />

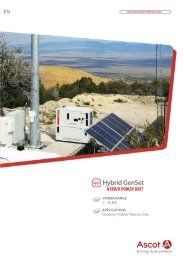

Controls<br />

Jobs<br />

Use<br />

Create<br />

Copy/delete<br />

Robots/automation<br />

Store button<br />

Function key<br />

Programs<br />

Stop point<br />

Manual<br />

Memory operation<br />

Welding process<br />

Double pulse<br />

Pulse<br />

Continuously variable<br />

Stick electrode<br />

LED<br />

Custom parameters<br />

Results<br />

Welding current<br />

Wire feed m/min<br />

Workpiece thickness<br />

Results<br />

Welding voltage<br />

Operating modes<br />

4-cycle with/without down-slope<br />

2-cycle with/without down-slope<br />

Spot<br />

40<br />

LED operation indicator<br />

Tuning<br />

arc output<br />

Arc length tuning<br />

(Arc length) correction<br />

LED spot time