EN welding technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

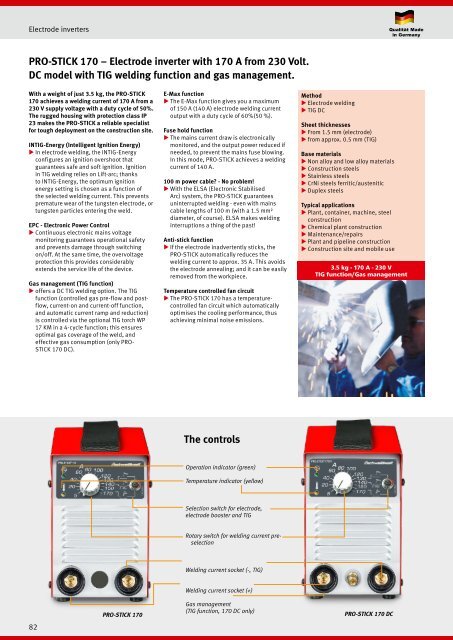

Electrode inverters<br />

Qualität Made<br />

in Germany<br />

PRO-STICK 170 – Electrode inverter with 170 A from 230 Volt.<br />

DC model with TIG <strong>welding</strong> function and gas management.<br />

With a weight of just 3.5 kg, the PRO-STICK<br />

170 achieves a <strong>welding</strong> current of 170 A from a<br />

230 V supply voltage with a duty cycle of 50%.<br />

The rugged housing with protection class IP<br />

23 makes the PRO-STICK a reliable specialist<br />

for tough deployment on the construction site.<br />

INTIG-Energy (Intelligent Ignition Energy)<br />

XXIn electrode <strong>welding</strong>, the INTIG-Energy<br />

configures an ignition overshoot that<br />

guarantees safe and soft ignition. Ignition<br />

in TIG <strong>welding</strong> relies on Lift-arc; thanks<br />

to INTIG-Energy, the optimum ignition<br />

energy setting is chosen as a function of<br />

the selected <strong>welding</strong> current. This prevents<br />

premature wear of the tungsten electrode, or<br />

tungsten particles entering the weld.<br />

EPC - Electronic Power Control<br />

XXContinuous electronic mains voltage<br />

monitoring guarantees operational safety<br />

and prevents damage through switching<br />

on/off. At the same time, the overvoltage<br />

protection this provides considerably<br />

extends the service life of the device.<br />

Gas management (TIG function)<br />

XXoffers a DC TIG <strong>welding</strong> option. The TIG<br />

function (controlled gas pre-flow and postflow,<br />

current-on and current-off function,<br />

and automatic current ramp and reduction)<br />

is controlled via the optional TIG torch WP<br />

17 KM in a 4-cycle function; this ensures<br />

optimal gas coverage of the weld, and<br />

effective gas consumption (only PRO-<br />

STICK 170 DC).<br />

E-Max function<br />

XXThe E-Max function gives you a maximum<br />

of 150 A (140 A) electrode <strong>welding</strong> current<br />

output with a duty cycle of 60%(50 %).<br />

Fuse hold function<br />

XXThe mains current draw is electronically<br />

monitored, and the output power reduced if<br />

needed, to prevent the mains fuse blowing.<br />

In this mode, PRO-STICK achieves a <strong>welding</strong><br />

current of 140 A.<br />

100 m power cable? - No problem!<br />

XXWith the ELSA (Electronic Stabilised<br />

Arc) system, the PRO-STICK guarantees<br />

uninterrupted <strong>welding</strong> - even with mains<br />

cable lengths of 100 m (with a 1.5 mm²<br />

diameter, of course). ELSA makes <strong>welding</strong><br />

interruptions a thing of the past!<br />

Anti-stick function<br />

XXIf the electrode inadvertently sticks, the<br />

PRO-STICK automatically reduces the<br />

<strong>welding</strong> current to approx. 35 A. This avoids<br />

the electrode annealing; and it can be easily<br />

removed from the workpiece.<br />

Temperature controlled fan circuit<br />

XXThe PRO-STICK 170 has a temperaturecontrolled<br />

fan circuit which automatically<br />

optimises the cooling performance, thus<br />

achieving minimal noise emissions.<br />

Method<br />

XXElectrode <strong>welding</strong><br />

XXTIG DC<br />

Sheet thicknesses<br />

XXFrom 1.5 mm (electrode)<br />

XXfrom approx. 0.5 mm (TIG)<br />

Base materials<br />

XXNon alloy and low alloy materials<br />

XXConstruction steels<br />

XXStainless steels<br />

XXCrNi steels ferritic/austenitic<br />

XXDuplex steels<br />

Typical applications<br />

XXPlant, container, machine, steel<br />

construction<br />

XXChemical plant construction<br />

XXMaintenance/repairs<br />

XXPlant and pipeline construction<br />

XXConstruction site and mobile use<br />

3.5 kg - 170 A - 230 V<br />

TIG function/Gas management<br />

The controls<br />

Operation indicator (green)<br />

Temperature indicator (yellow)<br />

Selection switch for electrode,<br />

electrode booster and TIG<br />

Rotary switch for <strong>welding</strong> current preselection<br />

Welding current socket (-, TIG)<br />

Welding current socket (+)<br />

82<br />

PRO-STICK 170<br />

Gas management<br />

(TIG function, 170 DC only)<br />

PRO-STICK 170 DC