- Page 1 and 2: PROCEEDINGS OF THE FOURTH U.S. WATE

- Page 3 and 4: FOREWORD The U.S. Water Jet Confere

- Page 5 and 6: FIELD APPLICATIONS- MINING Water Je

- Page 7 and 8: Figure 1. Abrasive-Waterjet Nozzle

- Page 9 and 10: N2 = ⋅ 2 d 2 j mav N = 3 N 4 Sett

- Page 11 and 12: • Although reasonable correlation

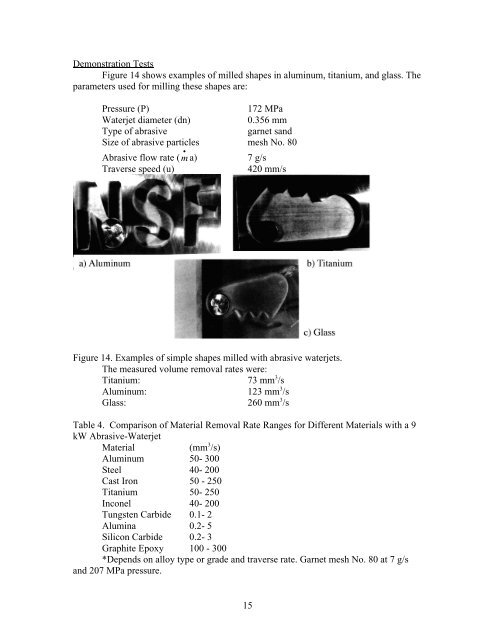

- Page 13 and 14: Effect of Traverse Speed Increasing

- Page 15 and 16: Table 3. Material removal rate and

- Page 17 and 18: Abrasive flow rate 7.5 g/s (maximum

- Page 19: where u is the traverse rate in mm/

- Page 23 and 24: this technique. The technique is al

- Page 25 and 26: 12. Preece, C., editor, "Treatise o

- Page 27 and 28: experiment was carried out to exami

- Page 29 and 30: of changes in jet pressure, nozzle

- Page 31 and 32: D = 0.0911 P 1.42 n 1.37 V −0.39

- Page 33 and 34: Figure 8. Average Specific Energy V

- Page 35 and 36: with the density of the material, o

- Page 37 and 38: PERCUSSIVE JETS—STATE-OF-THE-ART

- Page 39 and 40: This process of discharge modulatio

- Page 41 and 42: has been demonstrated on all types

- Page 43 and 44: 500 psig and 6,000 psig. Compressiv

- Page 45 and 46: Figure 6. STATIC IMPACTS ON COMMERC

- Page 47 and 48: not pursued because frequency, ampl

- Page 49 and 50: 12. Ponchot, W.D., "Hydrodynamic Mo

- Page 51 and 52: THEORETICAL ANALYSIS AND EXPERIMENT

- Page 53 and 54: D.Rockwell, E.Naudascher, Thomas an

- Page 55 and 56: Fig. 3 Flow model Hence we can comp

- Page 57 and 58: amplitude decreases suddenly when c

- Page 59 and 60: Where T: wave function period If we

- Page 61 and 62: Fig.14 Variation of dimensionless r

- Page 63 and 64: EXPERIMENTAL RESULT ANALYSIS (1) Th

- Page 65 and 66: Fig.19 Amplification factor versus

- Page 67 and 68: DYNAMIC CHARACTERISTICS OF WATERJET

- Page 69 and 70: A piezoelectric transducer (Kistler

- Page 71 and 72:

From the data obtained, it is clear

- Page 73 and 74:

conjectured that this optimum signa

- Page 75 and 76:

difference of impact forces with an

- Page 77 and 78:

The pressure of the jet is not an i

- Page 79 and 80:

near the nozzle exit in the mixing

- Page 81 and 82:

etween 0.5 mm and 1.5 mm. Full- fie

- Page 83 and 84:

earlier observations that cavitatio

- Page 85 and 86:

Obstructed Conical Nozzle The nozzl

- Page 87 and 88:

CONSIDERATIONS IN THE DESIGN OF A W

- Page 89 and 90:

An experimental mechanism was desig

- Page 91 and 92:

horn and the modification of the st

- Page 93 and 94:

ased on more detailed examination o

- Page 95 and 96:

DEVELOPMENT OF CAVITATING JET EQUIP

- Page 97 and 98:

hole, a total 23 minutes was requir

- Page 99 and 100:

from 1.5 to 4 ft to be cut. Other f

- Page 101 and 102:

Table 2 Summary of CCPC Pavement Cu

- Page 103 and 104:

All of the experimental modules wer

- Page 105 and 106:

Figure 10. Effect of CAVIJET R cutt

- Page 107 and 108:

HYDRO DEMOLITION - TECHNOLOGY FOR P

- Page 109 and 110:

Figure 1. Air entrained concrete pr

- Page 111 and 112:

TABLE II used a mean rating because

- Page 113 and 114:

As work loads grew and costs escala

- Page 115 and 116:

inches deep of deteriorated bridge

- Page 117 and 118:

Figure 6. Atlas Copco Conjet removi

- Page 119 and 120:

6. Total Ownership Cost Per Day $ 9

- Page 121 and 122:

ABRASIVE-WATERJET AND WATERJET TECH

- Page 123 and 124:

Commercial nuclear power plant deco

- Page 125 and 126:

Figure 3. Components of rotating no

- Page 127 and 128:

shroud and catching system designed

- Page 129 and 130:

Figure 9. Effect of abrasive size.

- Page 131 and 132:

alternative abrasive material. The

- Page 133 and 134:

four arms leading to nozzle holders

- Page 135 and 136:

surrounding grout, they tended to r

- Page 137 and 138:

12. Hashish, M. “Steel Cutting wi

- Page 139 and 140:

Figure 1 Kerf test stand pressure v

- Page 141 and 142:

Figure 3 Kerf area versus standoff

- Page 143 and 144:

The ratio of kerf depth to width or

- Page 145 and 146:

where: x c = u o d o ( ) (1) 4v e l

- Page 147 and 148:

Depending on the rock type γ can v

- Page 149 and 150:

CONICAL WATER JET DRILLING W. Dicki

- Page 151 and 152:

feed line. A conical cutting fluid

- Page 153 and 154:

A second series of tests at the ful

- Page 155 and 156:

Figure 8. 6061-T6 aluminum cut with

- Page 157 and 158:

serves to reduce tool wear (8). It

- Page 159 and 160:

Traverse speed is the velocity of t

- Page 161 and 162:

Figure 4: Diagram illustrating the

- Page 163 and 164:

The picture changes dramatically wh

- Page 165 and 166:

Analysis of the residuals of these

- Page 167 and 168:

5. Hood, M., "Cutting Strong Rock w

- Page 169 and 170:

hundred feet-per-second. At these v

- Page 171 and 172:

Figure 1. Typical Nozzle Configurat

- Page 173 and 174:

Figure 5. Expanded Signal from an I

- Page 175 and 176:

where: V w = water velocity F = mea

- Page 177 and 178:

HYDRO-ABRASIVE CUTTING HEAD—ENERG

- Page 179 and 180:

Figure 3. Percentage of initial abr

- Page 181 and 182:

Figure 6. Location of optimum recei

- Page 183 and 184:

WATER JET ASSISTED LONGWALL SHEARER

- Page 185 and 186:

• reduction of the proportion of

- Page 187 and 188:

The conversion set for the shearer

- Page 189 and 190:

into account. As far as possible no

- Page 191 and 192:

gal/yd 3 ). Another important influ

- Page 193 and 194:

At approximately 2 m/s (393 fpm), a

- Page 195 and 196:

Proceedings of the 8th Internationa

- Page 197 and 198:

κ = permeability of rock at atmosp

- Page 199 and 200:

operating parameters (P. V tr , etc

- Page 201 and 202:

κ = permeability at 1 atm. pressur

- Page 203 and 204:

was substantial gain in the depth o

- Page 205 and 206:

Figure 9. Plot of exposure rate aga

- Page 207 and 208:

For nozzle C2, a = 0.5 x 10 4 and b

- Page 209 and 210:

204

- Page 211 and 212:

Deep drilling or slotting requires

- Page 213 and 214:

imparted by an air motor coupled to

- Page 215 and 216:

Conventional rotary or percussive r

- Page 217 and 218:

A RELATIVE CLEANABILITY FACTOR A. F

- Page 219 and 220:

Relation [6] was used to derive the

- Page 221 and 222:

which has been observed for much of

- Page 223 and 224:

As part of a project to develop the

- Page 225 and 226:

Figure 1. Cost per square foot clea

- Page 227 and 228:

Abrasive Feed Rate The effect of ab

- Page 229 and 230:

Figure 4. Total cost per square foo

- Page 231 and 232:

3. Barker, C. R.; Mazurkiewicz, M.

- Page 233 and 234:

For our purposes here, we will lump

- Page 235 and 236:

Surface condensers can be cleaned b

- Page 237 and 238:

Some Powerlance customers have 20,0

- Page 239 and 240:

system could be designed that was o

- Page 241 and 242:

236

- Page 243 and 244:

ROTARY WATERBLAST LANCING MACHINES

- Page 245 and 246:

Motors and Gearing An advantage of

- Page 247 and 248:

The DuPont Company in LaPlace, Loui

- Page 249 and 250:

Fig 3 Heavy duty Rotary Lancing Mac

- Page 251 and 252:

D L - lower diameter of through hol

- Page 253 and 254:

Figure 1. A - single-pass, rough ke

- Page 255 and 256:

The erosion process is stochastic i

- Page 257 and 258:

three dimensional controlled erosio

- Page 259 and 260:

This can only be regarded as a simp

- Page 261 and 262:

approximately zero. Time constant T

- Page 263 and 264:

Figure 12. Transients of HAJM cycli

- Page 265 and 266:

T A = (f, h o, p, s o, f o, c, . .

- Page 267 and 268:

SURFACE FINISH CHARACTERIZATION IN

- Page 269 and 270:

FIG. 2 Force Sensor Designed for Cu

- Page 271 and 272:

system can be used in the developme

- Page 273 and 274:

Figure 8 Cutting Force versus Cutti

- Page 275 and 276:

nearly at the center of the ceramic

- Page 277 and 278:

ABRASIVE WATERJET CUTTING OF METAL

- Page 279 and 280:

Figure 1. Experimental setup, inclu

- Page 281 and 282:

Figure 3. Scanning microphotograph

- Page 283 and 284:

Figure 8. Effect of cutting speed o

- Page 285 and 286:

a. Scanning microphotograph, lOOOx

- Page 287 and 288:

c. Silicon image 1000x Figure 16. S