proceedings of the fourth us water jet conference - Waterjet ...

proceedings of the fourth us water jet conference - Waterjet ...

proceedings of the fourth us water jet conference - Waterjet ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

than against <strong>water</strong> hammer. C<strong>us</strong>hioning <strong>of</strong> <strong>the</strong> <strong>water</strong> hammer impact is not excessive if<br />

<strong>the</strong> bunch diameter is substantially greater than <strong>the</strong> film thickness, Ref. (12).<br />

Fur<strong>the</strong>rmore, <strong>the</strong> target is also attacked by cavitation produced at nuclei within <strong>the</strong> liquid<br />

film by <strong>the</strong> <strong>water</strong> hammer pressure wave, Ref. (13).<br />

Since <strong>the</strong> pressure levels generated on a target surface can be expected to be a<br />

major factor in determining <strong>the</strong> effectiveness <strong>of</strong> <strong>the</strong> cutting operation, estimating <strong>the</strong>se<br />

pressure levels is important. With a steady-state flow <strong>of</strong> <strong>water</strong> from a conventional<br />

steady-state <strong>jet</strong> impinging normally on a flat surface, <strong>the</strong> level <strong>of</strong> stress generated at <strong>the</strong><br />

stagnation point is given by:<br />

Ps = 1 2<br />

V<br />

2<br />

where:<br />

ρ is <strong>the</strong> <strong>water</strong> density<br />

V is <strong>the</strong> <strong>jet</strong> velocity.<br />

However in applications <strong>us</strong>ing <strong>the</strong> Perc<strong>us</strong>sive Jet where <strong>the</strong> <strong>water</strong> <strong>jet</strong> tends to<br />

break up to form discrete liquid droplets or bunches, <strong>the</strong> impact stress can be order <strong>of</strong><br />

magnitude higher P s. Numero<strong>us</strong> studies have indicated that <strong>the</strong> transient stress between a<br />

liquid droplet and rigid plane surface can be given approximately by <strong>the</strong> simplified <strong>water</strong><br />

hammer equation.<br />

where<br />

C is <strong>the</strong> aco<strong>us</strong>tive wave speed.<br />

P a = ρ C. V<br />

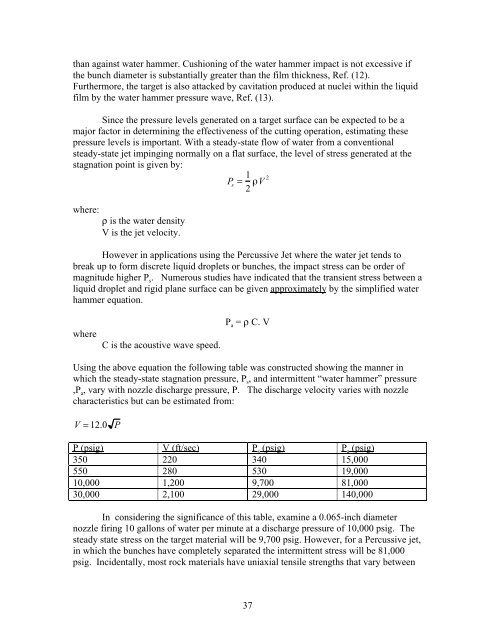

Using <strong>the</strong> above equation <strong>the</strong> following table was constructed showing <strong>the</strong> manner in<br />

which <strong>the</strong> steady-state stagnation pressure, P s, and intermittent “<strong>water</strong> hammer” pressure<br />

,P a, vary with nozzle discharge pressure, P. The discharge velocity varies with nozzle<br />

characteristics but can be estimated from:<br />

V = 12.0 P<br />

P (psig) V (ft/sec) P s (psig) P a (psig)<br />

350 220 340 15,000<br />

550 280 530 19,000<br />

10,000 1,200 9,700 81,000<br />

30,000 2,100 29,000 140,000<br />

In considering <strong>the</strong> significance <strong>of</strong> this table, examine a 0.065-inch diameter<br />

nozzle firing 10 gallons <strong>of</strong> <strong>water</strong> per minute at a discharge pressure <strong>of</strong> 10,000 psig. The<br />

steady state stress on <strong>the</strong> target material will be 9,700 psig. However, for a Perc<strong>us</strong>sive <strong>jet</strong>,<br />

in which <strong>the</strong> bunches have completely separated <strong>the</strong> intermittent stress will be 81,000<br />

psig. Incidentally, most rock materials have uniaxial tensile strengths that vary between<br />

37