FLEISCHWIRTSCHAFT international 1/2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

...............................<br />

...........................................................<br />

86<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2018</strong><br />

Research &Development<br />

The effects of different levels of iota- and kappa-carrageenan...<br />

Effects on viscosity<br />

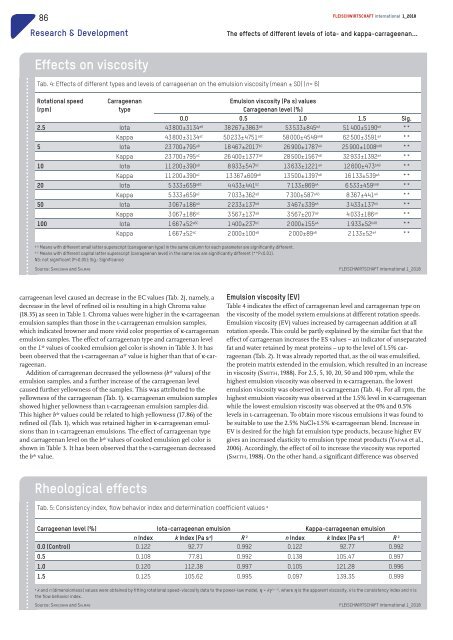

Tab. 4: Effects of different types and levels of carrageenan on the emulsion viscosity (mean ±SD) (n=6)<br />

Rotational speed<br />

(rpm)<br />

Carrageenan<br />

type<br />

Emulsion viscosity (Pa s) values<br />

Carrageenan level (%)<br />

0.0 0.5 1.0 1.5 Sig.<br />

2.5 Iota 43 800±3134 aB 38267±3863 bB 53 533±845 bA 51 400±5190 bA **<br />

Kappa 43 800±3134 aC 50 233±4751 aBC 58 000±4549 aAB 62 500±3591 aA **<br />

5 Iota 23 700±795 aB 18467±2017 bC 26 900±1787 aA 25 900±1008 bAB **<br />

Kappa 23 700±795 aC 26 400±1377 aB 28 500±1567 aB 32 933±1392 aA **<br />

10 Iota 11200±390 aB 8933±547 bC 13633±1221 aA 12600±473 bAB **<br />

Kappa 11200±390 aC 13367±609 aB 13500±1397 aB 16133±539 aA **<br />

20 Iota 5333±659 aBC 4433±441 bC 7133±869 aA 6533±459 bAB **<br />

Kappa 5333±659 aC 7033±362 aB 7300±587 aAB 8367±441 aA **<br />

50 Iota 3067±186 aA 2233±137 bB 3467±339 aA 3433±137 bA **<br />

Kappa 3067±186 aC 3567±137 aB 3567±207 aB 4033±186 aA **<br />

100 Iota 1667±52 aBC 1400±237 bC 2000±155 aA 1933±52 bAB **<br />

Kappa 1667±52 aC 2000±100 aB 2000±89 aB 2133±52 aA **<br />

a-b<br />

Meanswith differentsmall lettersuperscript(carrageenan type) in thesame column for each parameter are significantly different.<br />

A-C<br />

Means with different capitalletter superscript (carrageenan level) in thesame roware significantly different (**P0.05); Sig.: Significance<br />

Source: SARIÇOBAN and SALMAN <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 1_<strong>2018</strong><br />

carrageenan level caused an decrease in the EC values (Tab. 2), namely,a<br />

decrease in the level of refined oil is resulting in ahigh Chroma value<br />

(18.35) as seen in Table 1. Chromavalues were higher in the κ-carrageenan<br />

emulsion samples than those in the ι-carrageenan emulsion samples,<br />

which indicated browner and more vivid color properties of κ-carrageenan<br />

emulsion samples. The effect of carrageenan type and carrageenan level<br />

on the L* values of cooked emulsion gel color is shown in Table 3. It has<br />

been observed that the ι-carrageenan a* value is higher than that of κ-carrageenan.<br />

Addition of carrageenan decreased the yellowness (b* values) of the<br />

emulsion samples, and afurther increase of the carrageenan level<br />

caused further yellowness of the samples. This was attributed to the<br />

yellowness of the carrageenan (Tab. 1). κ-carrageenan emulsion samples<br />

showed higher yellowness than ι-carrageenan emulsion samples did.<br />

This higher b* values could be related to high yellowness (17.86) of the<br />

refined oil (Tab. 1),which was retained higher in κ-carrageenan emulsions<br />

than in ι-carrageenan emulsions. The effect of carrageenan type<br />

and carrageenan level on the b* values of cooked emulsion gel color is<br />

shown in Table 3. It has been observed that the ι-carrageenan decreased<br />

the b* value.<br />

Emulsion viscosity (EV)<br />

Table 4indicates the effect of carrageenan level and carrageenan type on<br />

the viscosity of the model system emulsions at different rotation speeds.<br />

Emulsion viscosity (EV) values increased by carrageenan addition at all<br />

rotation speeds. This could be partly explained by the similar fact that the<br />

effect of carrageenan increases the ES values –anindicator of unseparated<br />

fat and water retained by meat proteins –uptothe level of 1.5% carrageenan<br />

(Tab. 2). It was already reported that, as the oil was emulsified,<br />

the protein matrix extended in the emulsion, which resulted in an increase<br />

in viscosity (SMITH,1988). For2.5, 5, 10,20, 50 and 100rpm, while the<br />

highest emulsion viscosity was observed in κ-carrageenan, the lowest<br />

emulsion viscosity was observed in ι-carrageenan (Tab. 4). Forall rpm, the<br />

highest emulsion viscosity was observed at the 1.5% level in κ-carrageenan<br />

while the lowest emulsion viscosity was observed at the 0% and 0.5%<br />

levels in ι-carrageenan. To obtain more viscous emulsions it was found to<br />

be suitable to use the 2.5% NaCl+1.5% κ-carrageenan blend. Increase in<br />

EV is desired for the high fat emulsion type products, because higher EV<br />

gives an increased elasticity to emulsion type meat products (YAPAR et al.,<br />

2006). Accordingly,the effect of oil to increase the viscosity was reported<br />

(SMITH,1988). On the other hand, asignificant difference was observed<br />

Rheological effects<br />

Tab. 5: Consistency index, flow behavior index and determination coefficient values a<br />

Carrageenan level (%) Iota-carrageenan emulsion Kappa-carrageenan emulsion<br />

n Index k Index (Pa s n ) R 2 n Index k Index (Pa s n ) R 2<br />

0.0 (Control) 0.122 92.77 0.992 0.122 92.77 0.992<br />

0.5 0.108 77.81 0.992 0.138 105.47 0.997<br />

1.0 0.120 112.38 0.997 0.105 121.28 0.996<br />

1.5 0.125 105.62 0.995 0.097 139.35 0.999<br />

a<br />

k and n (dimensionless) values were obtained by fitting rotational speed-viscosity data to the power-law model, η = kγ (n -1) ,where η is the apparent viscosity, k is the consistency index and n is<br />

the flow behavior index.<br />

Source: SARIÇOBAN and SALMAN <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 1_<strong>2018</strong>