You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

transparency to our clients and gives them even more confidence in us.”<br />

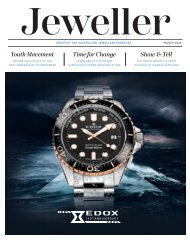

Nowlan also believes in the value of 3D printing.<br />

“We have specifically seen an increase in jewellers utilising 3D printing,<br />

including the Asiga range of 3D printers,” he says. “<strong>Jeweller</strong>s who are utilising<br />

this technology benefit from the ability to control the model manufacturing<br />

capability in-house and also check prototypes to identify potential design<br />

faults or issues prior to casting. This leads to a greater chance of success in the<br />

manufacturing process.”<br />

Desma Noble, a goldsmith and jeweller who owns Desma Designs, believes<br />

jewellers should be aware of innovations in welding technology also.<br />

“The techniques of making and repairing jewellery have barely changed for<br />

hundreds of years but new welding technology is changing that,” she says.<br />

“Electronic-fusion welding in jewellery enables a relatively instant, clean join with<br />

precise control through a digital interface and microscopic accuracy.”<br />

According to Noble, the benefits are large.<br />

“These techniques can bring incredible productivity to a jewellery workshop as<br />

very fine and delicate jewellery can be more easily repaired – metal joins can be<br />

within a millimetre of heat-sensitive gems and less oxidisation means very little<br />

finishing required,” she adds.<br />

LOOKING AHEAD<br />

The general consensus among<br />

the suppliers included here is that<br />

innovations are easing the burden<br />

and cost of manufacture and design<br />

and that these innovations should<br />

continue in coming years.<br />

OLYMPUS<br />

Botha sees the future as a melding of old<br />

and new technologies. “More Australian jewellers<br />

requiring low to mid-levels of product supply are leveraging<br />

online platforms,” he says. “These volumes will not be entertained by offshore<br />

manufacturers, so we’re seeing a marked increase in model-making and<br />

finishing in Australia. This is great news for the industry!<br />

“[We will also see] direct-metal printing and direct-mould printing,” he continues.<br />

“As per all other technologies, this will become cheaper and faster.”<br />

Sher concurs but believes such innovations might still take time to emerge here.<br />

“Direct metal printing could be an option if it becomes economically viable –<br />

currently, the machines are extremely expensive to run and the quality is not at<br />

the standards required,” he says.