FLEISCHWIRTSCHAFT international_04_2018

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

.......................................................<br />

Fleischwirtschaft <strong>international</strong> 4_<strong>2018</strong><br />

43<br />

Research & Development<br />

Calorific value<br />

Two grams of sample was electrically burnt in excess of oxygen in a bomb<br />

calorimeter. The maximum temperature rise of the bomb calorimeter was<br />

measured with a thermocouple and a galvanometer system. By comparing this<br />

rise with that obtained when a sample of known calorific value is burnt, the<br />

calorific value of the sample material could be determined. Gross energy of<br />

samples was determined by a Gallenkamp and Ballistic Bomb Calorimeter (HAQUE<br />

andMURALI LAL, 1999).<br />

Water activity (aw)<br />

The water activity of functional mutton patties was measured by an Aqua LAB<br />

dew point water activity meter 4TE.<br />

Total phenolics<br />

The total phenolic content in the phyto-ingredients powder and mutton patties<br />

were quantified using the Folin-Ciocalteu colorimetric method as described by<br />

MAKKAR (2000). Suitable aliquots of the extracts were taken in test tubes, and<br />

the volume was made upto 0.5 ml with distilled water and 0.25 ml Folin-Ciocalteu<br />

(1N) reagent was added and then the reaction was neutralized by addition<br />

with 1.25 ml sodium carbonate solution (20%). The tubes were vortexed and the<br />

absorbance of the resulting blue color was measured using a Beckman DU-640<br />

UV/Vis spectrophotometer at 760 nm against blank after incubation for 40min<br />

at room temperature. From the standard calibration curve equation y= f(x) the<br />

quantification of phenolics was done and expressed as mg tannic acid equivalents<br />

per gram of sample.<br />

Texture profile analysis<br />

The texture profile of mutton patties was measured with the help of instrumental<br />

texture profile analyzer (TAHD Plus Texture analyser). The procedure used for<br />

instrumental texture profile analysis was similar to those described by BOURNE<br />

(1978). Chilled samples were tempered to bring to room temperature and were<br />

cut into 1cm squares. The samples were placed on a platform in a fixture and<br />

compressed twice to 85% of their original height by a compression probe (P75)<br />

at a cross head speed of 10 mm/s through a two cycle sequence, using a 50 kg<br />

load cell.<br />

Antioxidant capacity<br />

Total Phenolics by F-C Method<br />

Dried (finely ground) phyto-ingredients powder (0.2g) was taken in a centrifuge<br />

tube of 25 ml capacity. 10 ml of aqueous acetone (70%) was added and subjected<br />

to centrifugation for 10 min at 3000 g in a REMI research centrifuge and<br />

then the contents were cooled by keeping the centrifuge tube in the refrigerator<br />

at 4±1°C (MAKKAR, 2000). Five gram of mutton patties was taken in a beaker<br />

of 100ml capacity. 25 ml of aqueous ice cold 70% acetone was added and<br />

subjected to homogenization for 60 s in an Ultra Turrax T25 tissue homogenizer<br />

(Janke and Kenkel IKA Labortechnik, Germany) and then the beaker was<br />

wrapped with aluminium foil and kept overnight for extraction at a refrigeration<br />

temperature of 4±1°C (NAVEENA et al., 2008).<br />

Preparation of a calibration curve using Standard Tannic Acid (TA)<br />

Table 1 shows the tannic acid stock standard concentration. The calibration<br />

curve was drawn and the equation was calculated in a Microsoft Excel 2007<br />

spread sheet. The linear correlation between standard concentration and<br />

absorbance was expressed with the equation y= f(x) and r 2 value. Where y=<br />

absorbance, x= standard concentration (µg/ml) and r 2 = correlation coefficient.<br />

Reducing power assay<br />

Suitable aliquots of the extracts containing 50 to 100 µg phenolics from<br />

phyto-ingredients and mutton patties were taken in test tubes, and the<br />

volume was made equal with acetone (70%) and mixed with 2.5 ml phosphate<br />

buffer (200 mM, pH 6.6) and 2.5 ml potassium ferricynide (1% w/v).<br />

This mixture was kept at 50 o C in a water bath for 20 min. After cooling,<br />

2.5 ml of 10% trichloro acetic acid was added and centrifuged at 5000 rpm<br />

for 10 min in a REMI research centrifuge. The upper layer of the solution<br />

(2.5 ml) was mixed with (2.5 ml) distilled water and 0.5 ml of freshly prepared<br />

ferric chloride (0.1% w/v) solution. The absorbance was measured<br />

using Beckman DU-640 UV/Vis spectrophotometer at 700 nm against<br />

blank without any extracts and 0.1% ferric chloride. An increase in absorbance<br />

of the reaction mixture indicated the reducing power of the<br />

sample.<br />

DPPH radical scavenging activity<br />

The ability to scavenge the 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical by<br />

phyto-ingredients and mutton patties was estimated by the method of<br />

SINGH et al. (2002). Different concentrations (50 and 100 µL equivalent to<br />

50 and 100ppm of total phenolics) of phyto-ingredients and mutton<br />

patties were taken in different test tubes. The volume was adjusted to<br />

100 µL by adding MeOH. 5ml of 0.1mM methanolic solution of DPPH was<br />

added to these tubes and shaken vigorously. The tubes were allowed to<br />

stand at 27 °C for 20 min. The control was prepared as above without any<br />

extract, and MeOH was used for the baseline correction. Changes in the<br />

absorbance of the samples were measured at 517 nm using a Beckman<br />

DU-640 UV-VIS spectrophotometer. The radical scavenging activity was<br />

expressed as the inhibition percentage and was calculated using the<br />

following formula:<br />

Calibration<br />

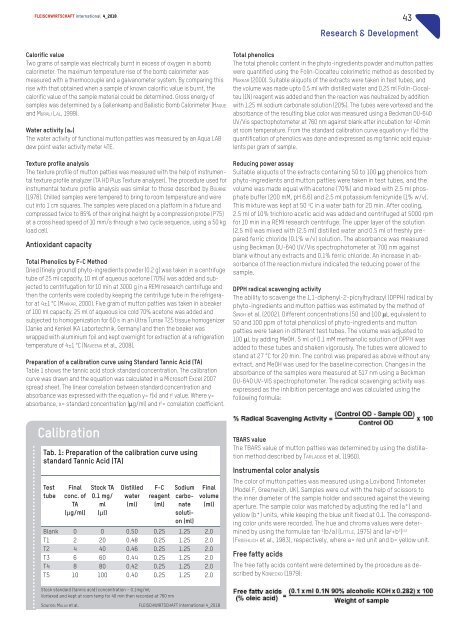

Tab. 1: Preparation of the calibration curve using<br />

standard Tannic Acid (TA)<br />

Test<br />

tube<br />

Final<br />

conc. of<br />

TA<br />

(µg/ml)<br />

Stock TA<br />

0.1 mg/<br />

ml<br />

(µl)<br />

Distilled<br />

water<br />

(ml)<br />

F-C<br />

reagent<br />

(ml)<br />

Sodium<br />

carbonate<br />

solution<br />

(ml)<br />

Final<br />

volume<br />

(ml)<br />

Blank 0 0 0.50 0.25 1.25 2.0<br />

T1 2 20 0.48 0.25 1.25 2.0<br />

T2 4 40 0.46 0.25 1.25 2.0<br />

T3 6 60 0.44 0.25 1.25 2.0<br />

T4 8 80 0.42 0.25 1.25 2.0<br />

T5 10 100 0.40 0.25 1.25 2.0<br />

Stock standard (tannic acid) concentration – 0.1mg/ml;<br />

Vortexed and kept at room temp for 40 min then recorded at 760 nm<br />

Source: MALAV et al. <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 4_<strong>2018</strong><br />

TBARS value<br />

The TBARS value of mutton patties was determined by using the distillation<br />

method described by TARLADGIS et al. (1960).<br />

Instrumental color analysis<br />

The color of mutton patties was measured using a Lovibond Tintometer<br />

(Model F, Greenwich, UK). Samples were cut with the help of scissors to<br />

the inner diameter of the sample holder and secured against the viewing<br />

aperture. The sample color was matched by adjusting the red (a*) and<br />

yellow (b*) units, while keeping the blue unit fixed at 0.1. The corresponding<br />

color units were recorded. The hue and chroma values were determined<br />

by using the formulae tan -1 (b/a) (LITTLE, 1975) and (a 2 +b 2 ) 1/2<br />

(FROEHLICH et al., 1983), respectively, where a= red unit and b= yellow unit.<br />

Free fatty acids<br />

The free fatty acids content were determined by the procedure as described<br />

by KONIECKO (1979):