FLEISCHWIRTSCHAFT international_04_2018

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

......................................................................................<br />

................................................................................................................................................................<br />

Fleischwirtschaft <strong>international</strong> 4_<strong>2018</strong><br />

45<br />

Research & Development<br />

might be due to a comparatively<br />

higher proportion of orange pulp<br />

in blend C. Emulsion stability for<br />

all treatments was insignificantly<br />

higher (P>0.05) than control. The<br />

pH values for the treatment<br />

products were marginally lower<br />

than control and there was decline<br />

in product pH from blend A<br />

to C. The decreasing trend in<br />

product and emulsion pH from<br />

blend A to C might be due to<br />

progressively increasing levels of<br />

orange pulp in blends which have<br />

acidic nature.<br />

The cooking yields of all treatment<br />

products were marginally<br />

higher than control. It could be<br />

attributed to the characteristic<br />

properties of non-meat additives<br />

to bind the water (REITMER and<br />

PRUSA, 1991).<br />

The moisture percentage for<br />

treatment products with blend A<br />

and C were significantly higher<br />

(P0.05) than<br />

control, which could be due to a<br />

higher mineral content of plant<br />

materials as compared to lean<br />

meat. The shear force values of<br />

treatment products with blends A<br />

and B were comparable to control.<br />

Lower shear force values for<br />

treatments in comparison to<br />

control might be due to higher<br />

moisture retention.<br />

Mean sensory scores of functional<br />

mutton patties incorporated<br />

with three different combinations<br />

of plant materials i.e.<br />

Product profile<br />

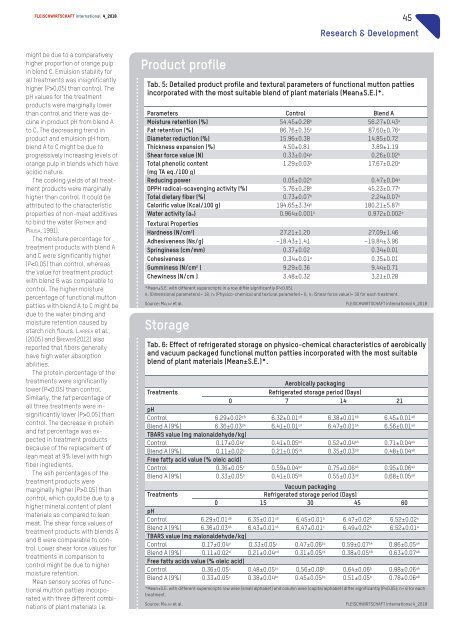

Tab. 5: Detailed product profile and textural parameters of functional mutton patties<br />

incorporated with the most suitable blend of plant materials (Mean±S.E.)*.<br />

Parameters Control Blend A<br />

Moisture retention (%) 54.45±0.28 b 56.27±0.43 a<br />

Fat retention (%) 86.76±0.35 b 87.60±0.76 a<br />

Diameter reduction (%) 15.96±0.38 14.85±0.72<br />

Thickness expansion (%) 4.50±0.81 3.89±1.19<br />

Shear force value (N) 0.33±0.<strong>04</strong> a 0.26±0.02 b<br />

Total phenolic content<br />

1.29±0.03 b 17.67±0.20 a<br />

(mg TA eq./100 g)<br />

Reducing power 0.05±0.02 b 0.47±0.<strong>04</strong> a<br />

DPPH radical-scavenging activity (%) 5.76±0.28 b 45.23±0.77 a<br />

Total dietary fiber (%) 0.73±0.07 b 2.24±0.07 a<br />

Calorific value (Kcal/100 g) 194.65±3.34 a 180.21±5.87 b<br />

Water activity (aw) 0.964±0.001 b 0.972±0.002 a<br />

Textural Properties<br />

Hardness (N/cm 2 ) 27.21±1.20 27.09±1.46<br />

Adhesiveness (Ns/g) –18.43±1.41 –19.84±3.96<br />

Springiness (cm/mm) 0.37±0.02 0.34±0.01<br />

Cohesiveness 0.34±0.01 a 0.35±0.01<br />

Gumminess (N/cm 2 ) 9.29±0.36 9.44±0.71<br />

Chewiness (N/cm ) 3.48±0.32 3.21±0.28<br />

*Mean±S.E. with different superscripts in a row differ significantly (P