AlitInform 50

“ALITinform” is a periodical that covers different aspects in production and applications of cement, concrete, and dry building mixtures. Pages of this journal offer contributions from leading Russian and International scientists, technologists and leading professionals, news from the stock markets, research laboratories, latest elaborations by producers and suppliers of modern building materials and equipment. The magazine goal is to unite on its pages the articles of the leading Russian and International specialists in the field of cement, concrete, dry building mixtures; latest news of the Russian and world building materials market, the traditions of peer-reviewed Russian scientific magazines and innovative informational approach of the contemporary printed media. The prime focus is on developments serving the purpose of rationalization of production, reduction of energy consumption, enhancement of quality and improvement of environmental safety. _______________________________________

“ALITinform” is a periodical that covers different aspects in production and applications of cement, concrete, and dry building mixtures. Pages of this journal offer contributions from leading Russian and International scientists, technologists and leading professionals, news from the stock markets, research laboratories, latest elaborations by producers and suppliers of modern building materials and equipment.

The magazine goal is to unite on its pages the articles of the leading Russian and International specialists in the field of cement, concrete, dry building mixtures; latest news of the Russian and world building materials market, the traditions of peer-reviewed Russian scientific magazines and innovative informational approach of the contemporary printed media. The prime focus is on developments serving the purpose of rationalization of production, reduction of energy consumption, enhancement of quality and improvement of environmental safety.

_______________________________________

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

concrete | бетон<br />

The first test method can be used later for quality control<br />

on site, but since its results strongly depend on the concrete<br />

density, it is not suited for lightweight concrete<br />

for determining a consistency class. This was declared<br />

based on the degree of compactability. The mix was selfcompacting<br />

until 60 minutes after the start of mixing<br />

according to the degree of compactability (consistency<br />

class C4). The concrete delivered on site had consistency<br />

class C3. Its effective workability on site confirmed that<br />

the results of the degree of compactability measurements<br />

are representative for such mixes other than the flow table<br />

results which indicated a stiffer mix (class F2).<br />

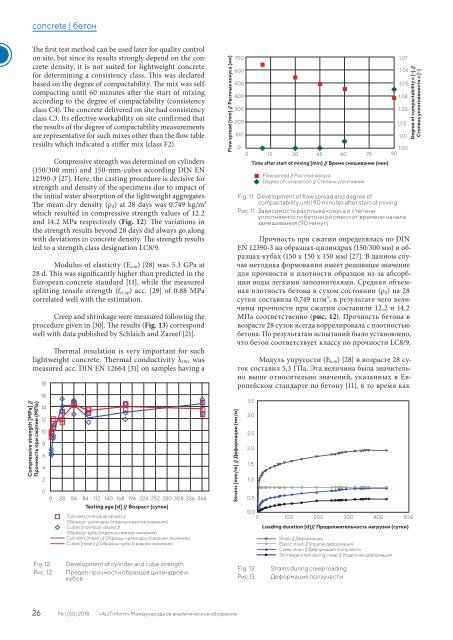

Compressive strength was determined on cylinders<br />

(1<strong>50</strong>/300 mm) and 1<strong>50</strong>-mm-cubes according DIN EN<br />

12390-3 [27]. Here, the casting procedure is decisive for<br />

strength and density of the specimens due to impact of<br />

the initial water absorption of the lightweight aggregates.<br />

The mean dry density (ρ d ) at 28 days was 0.749 kg/m3<br />

which resulted in compressive strength values of 12.2<br />

and 14.2 MPa respectively (Fig. 12). The variations in<br />

the strength results beyond 28 days did always go along<br />

with deviations in concrete density. The strength results<br />

led to a strength class designation LC8/9.<br />

Modulus of elasticity (E lcm ) [28] was 5.3 GPa at<br />

28 d. This was significantly higher than predicted in the<br />

European concrete standard [11], while the measured<br />

splitting tensile strength (f ct,sp ) acc. [29] of 0.88 MPa<br />

correlated well with the estimation.<br />

Creep and shrinkage were measured following the<br />

procedure given in [30]. The results (Fig. 13) correspond<br />

well with data published by Schlaich and Zareef [21].<br />

Thermal insulation is very important for such<br />

lightweight concrete. Thermal conductivity λ 10tr was<br />

measured acc. DIN EN 12664 [31] on samples having a<br />

Compressive strength [MPa] //<br />

Прочность при сжатии (МПа)<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Fig. 12.<br />

Рис. 12.<br />

0 28 56 84 112<br />

140 168 196 224 252 280 308 336 364<br />

Testing age [d] // Возраст (сутки)<br />

Cylinders (individual values) //<br />

Образцы-цилиндры (отдельно взятые значения)<br />

Cubes (individual values) //<br />

Образцы-кубы (отдельно взятые значения)<br />

Cylinders (mean) // Образцы-цилиндры (среднее значение)<br />

Cubes (mean) // Образцы-кубы (среднее значение)<br />

Development of cylinder and cube strength<br />

Предел прочности образцов цилиндров и<br />

кубов<br />

Flow spread [mm] // Расплыв конуса (мм)<br />

700<br />

600<br />

<strong>50</strong>0<br />

400<br />

300<br />

200<br />

Strains [mm/m] // Деформации (мм/м)<br />

100<br />

0<br />

0 15 30 45 60<br />

Fig. 11. Development of flow spread and degree of<br />

compactability until 90 minutes after start of mixing<br />

Рис. 11. Зависимость расплыва конуса и степени<br />

уплотняемости бетонной смеси от времени начала<br />

замешивания (90 минут)<br />

Прочность при сжатии определялась по DIN<br />

EN 12390-3 на образцах-цилиндрах (1<strong>50</strong>/300 мм) и образцах-кубах<br />

(1<strong>50</strong> х 1<strong>50</strong> х 1<strong>50</strong> мм) [27]. В данном случае<br />

методика формования имеет решающее значение<br />

для прочности и плотности образцов из-за абсорбции<br />

воды легкими заполнителями. Средняя объемная<br />

плотность бетона в сухом состоянии (ρ d ) на 28<br />

сутки составила 0,749 кг/м 3 , в результате чего величины<br />

прочности при сжатии составили 12,2 и 14,2<br />

МПа соответственно (рис. 12). Прочность бетона в<br />

возрасте 28 суток всегда коррелировала с плотностью<br />

бетона. По результатам испытаний было установлено,<br />

что бетон соответствует классу по прочности LC8/9.<br />

Модуль упругости (E lcm ) [28] в возрасте 28 суток<br />

составил 5,3 ГПа. Эта величина была значительно<br />

выше относительно значений, указанных в Европейском<br />

стандарте по бетону [11], в то время как<br />

3,5<br />

3,0<br />

2,5<br />

2,0<br />

1,5<br />

1,0<br />

0,5<br />

Fig. 13.<br />

Рис. 13.<br />

Time after start of mixing [min] // Время смешивания (мин)<br />

Flow spread // Расплыв конуса<br />

Degree of compaction // Степень уплотнения<br />

0,0<br />

0 100<br />

Strains during creep loading<br />

Деформация ползучести<br />

1,07<br />

1,06<br />

1,05<br />

1,04<br />

1,03<br />

1,02<br />

1,01<br />

1,00<br />

75 90<br />

200 300 400 <strong>50</strong>0<br />

Loading duration [d]// Продолжительность нагрузки (сутки)<br />

Strain // Деформация<br />

Elastic strain // Упругая деформация<br />

Creep strain // Деформация ползучести<br />

Shrinkage strain during creep // Усадочная деформация<br />

Degree of compactability с [-] //<br />

Степень уплотняемости с [-]<br />

26 № 1 (<strong>50</strong>) 2018 «ALITinform» Международное аналитическое обозрение