AlitInform 50

“ALITinform” is a periodical that covers different aspects in production and applications of cement, concrete, and dry building mixtures. Pages of this journal offer contributions from leading Russian and International scientists, technologists and leading professionals, news from the stock markets, research laboratories, latest elaborations by producers and suppliers of modern building materials and equipment. The magazine goal is to unite on its pages the articles of the leading Russian and International specialists in the field of cement, concrete, dry building mixtures; latest news of the Russian and world building materials market, the traditions of peer-reviewed Russian scientific magazines and innovative informational approach of the contemporary printed media. The prime focus is on developments serving the purpose of rationalization of production, reduction of energy consumption, enhancement of quality and improvement of environmental safety. _______________________________________

“ALITinform” is a periodical that covers different aspects in production and applications of cement, concrete, and dry building mixtures. Pages of this journal offer contributions from leading Russian and International scientists, technologists and leading professionals, news from the stock markets, research laboratories, latest elaborations by producers and suppliers of modern building materials and equipment.

The magazine goal is to unite on its pages the articles of the leading Russian and International specialists in the field of cement, concrete, dry building mixtures; latest news of the Russian and world building materials market, the traditions of peer-reviewed Russian scientific magazines and innovative informational approach of the contemporary printed media. The prime focus is on developments serving the purpose of rationalization of production, reduction of energy consumption, enhancement of quality and improvement of environmental safety.

_______________________________________

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

concrete | бетон<br />

then can polymerize with maleic anhydride to form<br />

a PCE structure [29]. In this polymer, MPEG provides<br />

the backbone as well as the side chain while maleic<br />

anhydride delivers the carboxylate anchoring group<br />

and the linkage to the side chain (Fig. 2).<br />

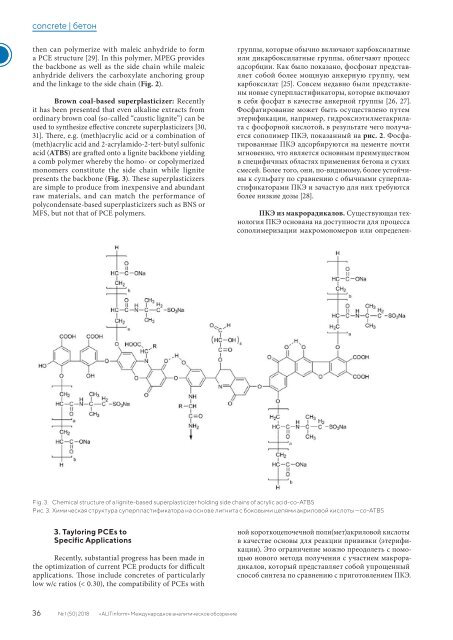

Brown coal-based superplasticizer: Recently<br />

it has been presented that even alkaline extracts from<br />

ordinary brown coal (so-called “caustic lignite”) can be<br />

used to synthesize effective concrete superplasticizers [30,<br />

31]. There, e.g. (meth)acrylic acid or a combination of<br />

(meth)acrylic acid and 2-acrylamido-2-tert-butyl sulfonic<br />

acid (ATBS) are grafted onto a lignite backbone yielding<br />

a comb polymer whereby the homo- or copolymerized<br />

monomers constitute the side chain while lignite<br />

presents the backbone (Fig. 3). These superplasticizers<br />

are simple to produce from inexpensive and abundant<br />

raw materials, and can match the performance of<br />

polycondensate-based superplasticizers such as BNS or<br />

MFS, but not that of PCE polymers.<br />

группы, которые обычно включают карбоксилатные<br />

или дикарбоксилатные группы, облегчают процесс<br />

адсорбции. Как было показано, фосфонат представляет<br />

собой более мощную анкерную группу, чем<br />

карбоксилат [25]. Совсем недавно были представлены<br />

новые суперпластификаторы, которые включают<br />

в себя фосфат в качестве анкерной группы [26, 27].<br />

Фосфатирование может быть осуществлено путем<br />

этерификации, например, гидроксиэтилметакрилата<br />

с фосфорной кислотой, в результате чего получается<br />

сополимер ПКЭ, показанный на рис. 2. Фосфатированные<br />

ПКЭ адсорбируются на цементе почти<br />

мгновенно, что является основным преимуществом<br />

в специфичных областях применения бетона и сухих<br />

смесей. Более того, они, по-видимому, более устойчивы<br />

к сульфату по сравнению с обычными суперпластификаторами<br />

ПКЭ и зачастую для них требуются<br />

более низкие дозы [28].<br />

Fig. 3. Chemical structure of a lignite-based superplasticizer holding side chains of acrylic acid-co-ATBS<br />

Рис. 3. Химическая структура суперпластификатора на основе лигнита с боковыми цепями акриловой кислоты —co-ATBS<br />

3. Tayloring PCEs to<br />

Specific Applications<br />

Recently, substantial progress has been made in<br />

the optimization of current PCE products for difficult<br />

applications. Those include concretes of particularly<br />

low w/c ratios (< 0.30), the compatibility of PCEs with<br />

ПКЭ из макрорадикалов. Существующая технология<br />

ПКЭ основана на доступности для процесса<br />

сополимеризации макромономеров или определенной<br />

короткоцепочечной поли(мет)акриловой кислоты<br />

в качестве основы для реакции прививки (этерификации).<br />

Это ограничение можно преодолеть с помощью<br />

нового метода получения с участием макрорадикалов,<br />

который представляет собой упрощенный<br />

способ синтеза по сравнению с приготовлением ПКЭ.<br />

36 № 1 (<strong>50</strong>) 2018 «ALITinform» Международное аналитическое обозрение