AlitInform 50

“ALITinform” is a periodical that covers different aspects in production and applications of cement, concrete, and dry building mixtures. Pages of this journal offer contributions from leading Russian and International scientists, technologists and leading professionals, news from the stock markets, research laboratories, latest elaborations by producers and suppliers of modern building materials and equipment. The magazine goal is to unite on its pages the articles of the leading Russian and International specialists in the field of cement, concrete, dry building mixtures; latest news of the Russian and world building materials market, the traditions of peer-reviewed Russian scientific magazines and innovative informational approach of the contemporary printed media. The prime focus is on developments serving the purpose of rationalization of production, reduction of energy consumption, enhancement of quality and improvement of environmental safety. _______________________________________

“ALITinform” is a periodical that covers different aspects in production and applications of cement, concrete, and dry building mixtures. Pages of this journal offer contributions from leading Russian and International scientists, technologists and leading professionals, news from the stock markets, research laboratories, latest elaborations by producers and suppliers of modern building materials and equipment.

The magazine goal is to unite on its pages the articles of the leading Russian and International specialists in the field of cement, concrete, dry building mixtures; latest news of the Russian and world building materials market, the traditions of peer-reviewed Russian scientific magazines and innovative informational approach of the contemporary printed media. The prime focus is on developments serving the purpose of rationalization of production, reduction of energy consumption, enhancement of quality and improvement of environmental safety.

_______________________________________

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

market | рынок<br />

SK<br />

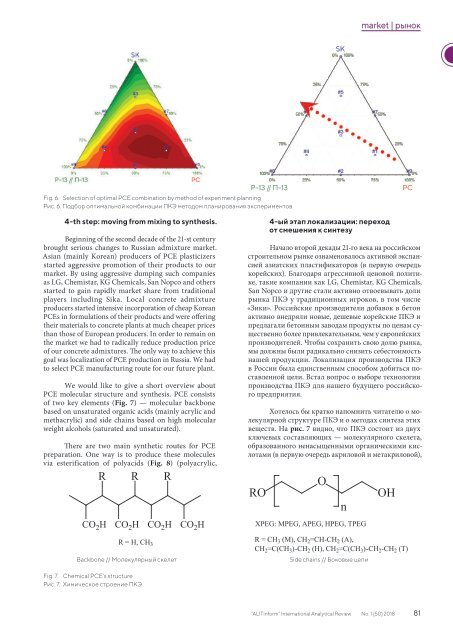

Fig. 6. Selection of optimal PCE combination by method of experiment planning<br />

Рис. 6. Подбор оптимальной комбинации ПКЭ методом планирования экспериментов<br />

P-13 // П-13 PC<br />

4-th step: moving from mixing to synthesis.<br />

Beginning of the second decade of the 21-st century<br />

brought serious changes to Russian admixture market.<br />

Asian (mainly Korean) producers of PCE plasticizers<br />

started aggressive promotion of their products to our<br />

market. By using aggressive dumping such companies<br />

as LG, Chemistar, KG Chemicals, San Nopco and others<br />

started to gain rapidly market share from traditional<br />

players including Sika. Local concrete admixture<br />

producers started intensive incorporation of cheap Korean<br />

PCEs in formulations of their products and were offering<br />

their materials to concrete plants at much cheaper prices<br />

than those of European producers. In order to remain on<br />

the market we had to radically reduce production price<br />

of our concrete admixtures. The only way to achieve this<br />

goal was localization of PCE production in Russia. We had<br />

to select PCE manufacturing route for our future plant.<br />

We would like to give a short overview about<br />

PCE molecular structure and synthesis. PCE consists<br />

of two key elements (Fig. 7) — molecular backbone<br />

based on unsaturated organic acids (mainly acrylic and<br />

methacrylic) and side chains based on high molecular<br />

weight alcohols (saturated and unsaturated).<br />

There are two main synthetic routes for PCE<br />

preparation. One way is to produce these molecules<br />

via esterification of polyacids (Fig. 8) (polyacrylic,<br />

R<br />

R<br />

R = H, CH 3<br />

R<br />

CO 2 H CO 2 H CO 2 H CO 2 H<br />

Backbone // Молекулярный скелет<br />

4-ый этап локализации: переход<br />

от смешения к синтезу<br />

Начало второй декады 21-го века на российском<br />

строительном рынке ознаменовалось активной экспансией<br />

азиатских пластификаторов (в первую очередь<br />

корейских). Благодаря агрессивной ценовой политике,<br />

такие компании как LG, Chemistar, KG Chemicals,<br />

San Nopco и другие стали активно отвоевывать доли<br />

рынка ПКЭ у традиционных игроков, в том числе<br />

«Зики». Российские производители добавок в бетон<br />

активно внедряли новые, дешевые корейские ПКЭ и<br />

предлагали бетонным заводам продукты по ценам существенно<br />

более привлекательным, чем у европейских<br />

производителей. Чтобы сохранить свою долю рынка,<br />

мы должны были радикально снизить себестоимость<br />

нашей продукции. Локализация производства ПКЭ<br />

в России была единственным способом добиться поставленной<br />

цели. Встал вопрос о выборе технологии<br />

производства ПКЭ для нашего будущего российского<br />

предприятия.<br />

Хотелось бы кратко напомнить читателю о молекулярной<br />

структуре ПКЭ и о методах синтеза этих<br />

веществ. На рис. 7 видно, что ПКЭ состоит из двух<br />

ключевых составляющих — молекулярного скелета,<br />

образованного ненасыщенными органическими кислотами<br />

(в первую очередь акриловой и метакриловой),<br />

RO<br />

O<br />

n<br />

XPEG: MPEG, APEG, HPEG, TPEG<br />

OH<br />

R = CH 3 (M), CH 2 =CH-CH 2 (A),<br />

CH 2 =C(CH 3 )-CH 2 (H), CH 2 =C(CH 3 )-CH 2 -CH 2 (T)<br />

Side chains // Боковые цепи<br />

Fig. 7. Chemical PCE’s structure<br />

Рис. 7. Химическое строение ПКЭ<br />

“ALITinform” International Analytical Review No. 1 (<strong>50</strong>) 2018<br />

81