CPT International 02/2019

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

COMPONENT DEVELOPMENT<br />

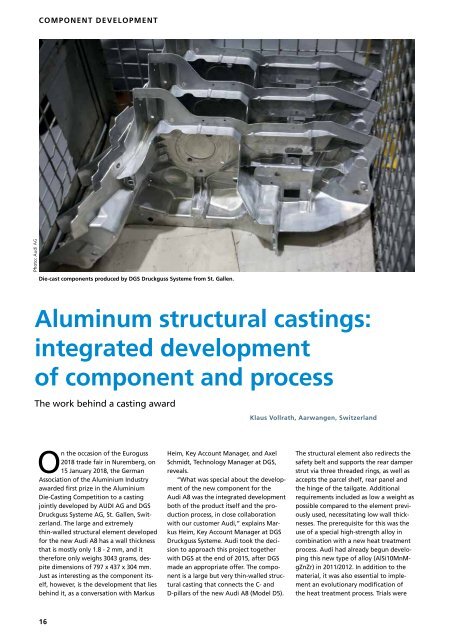

Photo: Audi AG<br />

Die-cast components produced by DGS Druckguss Systeme from St. Gallen.<br />

Aluminum structural castings:<br />

integrated development<br />

of component and process<br />

The work behind a casting award<br />

Klaus Vollrath, Aarwangen, Switzerland<br />

On the occasion of the Euroguss<br />

2018 trade fair in Nuremberg, on<br />

15 January 2018, the German<br />

Association of the Aluminium Industry<br />

awarded first prize in the Aluminium<br />

Die-Casting Competition to a casting<br />

jointly developed by AUDI AG and DGS<br />

Druckguss Systeme AG, St. Gallen, Switzerland.<br />

The large and extremely<br />

thin-walled structural element developed<br />

for the new Audi A8 has a wall thickness<br />

that is mostly only 1.8 - 2 mm, and it<br />

there fore only weighs 3043 grams, despite<br />

dimensions of 797 x 437 x 304 mm.<br />

Just as interesting as the component itself,<br />

however, is the development that lies<br />

behind it, as a conversation with Markus<br />

Heim, Key Account Manager, and Axel<br />

Schmidt, Technology Manager at DGS,<br />

reveals.<br />

“What was special about the development<br />

of the new component for the<br />

Audi A8 was the integrated development<br />

both of the product itself and the production<br />

process, in close collaboration<br />

with our customer Audi,” explains Markus<br />

Heim, Key Account Manager at DGS<br />

Druckguss Systeme. Audi took the decision<br />

to approach this project together<br />

with DGS at the end of 2015, after DGS<br />

made an appropriate offer. The component<br />

is a large but very thin-walled structural<br />

casting that connects the C- and<br />

D-pillars of the new Audi A8 (Model D5).<br />

The structural element also redirects the<br />

safety belt and supports the rear damper<br />

strut via three threaded rings, as well as<br />

accepts the parcel shelf, rear panel and<br />

the hinge of the tailgate. Additional<br />

requirements included as low a weight as<br />

possible compared to the element previously<br />

used, necessitating low wall thicknesses.<br />

The prerequisite for this was the<br />

use of a special high-strength alloy in<br />

combination with a new heat treatment<br />

process. Audi had already begun developing<br />

this new type of alloy (AlSi10MnMgZnZr)<br />

in 2011/2012. In addition to the<br />

material, it was also essential to implement<br />

an evolutionary modification of<br />

the heat treatment process. Trials were<br />

16