CPT International 02/2019

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GIFA <strong>2019</strong><br />

hall 16 / C11<br />

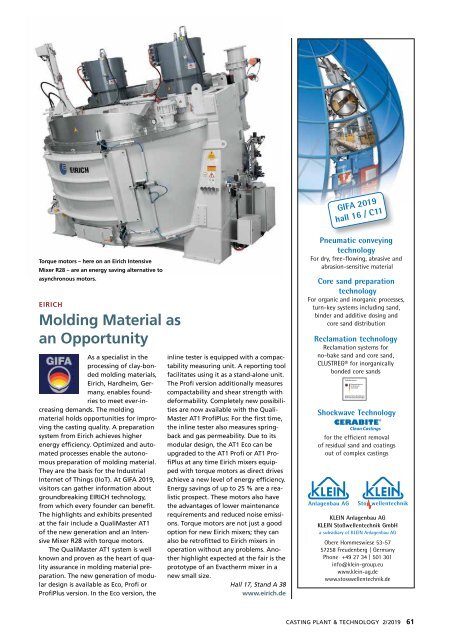

Torque motors – here on an Eirich Intensive<br />

Mixer R28 – are an energy saving alternative to<br />

asynchronous motors.<br />

EIRICH<br />

Molding Material as<br />

an Opportunity<br />

As a specialist in the<br />

processing of clay-bonded<br />

molding materials,<br />

Eirich, Hardheim, Germany,<br />

enables foundries<br />

to meet ever-increasing<br />

demands. The molding<br />

material holds opportunities for improving<br />

the casting quality. A preparation<br />

system from Eirich achieves higher<br />

energy efficiency. Optimized and automated<br />

processes enable the autonomous<br />

preparation of molding material.<br />

They are the basis for the Industrial<br />

Internet of Things (IIoT). At GIFA <strong>2019</strong>,<br />

visitors can gather information about<br />

groundbreaking EIRICH technology,<br />

from which every founder can benefit.<br />

The highlights and exhibits presented<br />

at the fair include a QualiMaster AT1<br />

of the new generation and an Intensive<br />

Mixer R28 with torque motors.<br />

The QualiMaster AT1 system is well<br />

known and proven as the heart of quality<br />

assurance in molding material preparation.<br />

The new generation of modular<br />

design is available as Eco, Profi or<br />

ProfiPlus version. In the Eco version, the<br />

inline tester is equipped with a compactability<br />

measuring unit. A reporting tool<br />

facilitates using it as a stand-alone unit.<br />

The Profi version additionally measures<br />

compactability and shear strength with<br />

deformability. Completely new possibilities<br />

are now available with the Quali-<br />

Master AT1 ProfiPlus: For the first time,<br />

the inline tester also measures springback<br />

and gas permeability. Due to its<br />

modular design, the AT1 Eco can be<br />

upgraded to the AT1 Profi or AT1 ProfiPlus<br />

at any time Eirich mixers equipped<br />

with torque motors as direct drives<br />

achieve a new level of energy efficiency.<br />

Energy savings of up to 25 % are a realistic<br />

prospect. These motors also have<br />

the advantages of lower maintenance<br />

requirements and reduced noise emissions.<br />

Torque motors are not just a good<br />

option for new Eirich mixers; they can<br />

also be retrofitted to Eirich mixers in<br />

operation without any problems. Another<br />

highlight expected at the fair is the<br />

prototype of an Evactherm mixer in a<br />

new small size.<br />

Hall 17, Stand A 38<br />

www.eirich.de<br />

Pneumatic conveying<br />

technology<br />

For dry, free-flowing, abrasive and<br />

abrasion-sensitive material<br />

Core sand preparation<br />

technology<br />

For organic and inorganic processes,<br />

turn-key systems including sand,<br />

binder and additive dosing and<br />

core sand distribution<br />

Reclamation technology<br />

Reclamation systems for<br />

no-bake sand and core sand,<br />

CLUSTREG® for inorganically<br />

bonded core sands<br />

Shockwave Technology<br />

CERABITE ®<br />

Clean Castings<br />

for the efficient removal<br />

of residual sand and coatings<br />

out of complex castings<br />

KLEIN Anlagenbau AG<br />

KLEIN Stoßwellentechnik GmbH<br />

a subsidiary of KLEIN Anlagenbau AG<br />

Obere Hommeswiese 53-57<br />

57258 Freudenberg | Germany<br />

Phone +49 27 34 | 501 301<br />

info@klein-group.eu<br />

www.klein-ag.de<br />

www.stosswellentechnik.de<br />

CASTING PLANT & TECHNOLOGY 2/<strong>2019</strong> 61