CPT International 02/2019

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Kinetic Assembly Structure reflects the materialization<br />

of a train of thought. The lines form an infinite<br />

loop. voxeljet printed the models of the complex<br />

sculpture in several parts.<br />

The stool „Infiniala“ by designer<br />

Sergej Ehret: Future of Sculpture.<br />

With voxeljet 3-D printing systems,<br />

even the most complex<br />

sculptures that would have been<br />

impossible using traditional molding<br />

techniques can be realized.<br />

3-D printing systems evolutionize<br />

traditional art casting<br />

Art foundry Strassacker creates artistic works using 3-D printing systems by voxeljet<br />

Frederik von Saldern, Friedberg; Peter Mühlhäuser, Süßen<br />

Photos: Voxeljet<br />

Strassacker, one of the oldest and<br />

largest art foundries in Europe, is<br />

modernizing art casting with 3-D<br />

printing from voxeljet, Friedberg, Germany.<br />

The printing technology is used<br />

to create investment casting patterns<br />

and increases the artists’ freedom of<br />

design. Artworks which previously could<br />

not be produced using traditional molding<br />

techniques can now be printed<br />

directly in the form of a casting pattern.<br />

Have you heard of The Bambi<br />

Award? The German Media and Television<br />

Prize, which is awarded annually to<br />

people with visions and for outstanding<br />

achievements? The award winners<br />

include world stars such as Christoph<br />

Waltz, Samuel L. Jackson and Kate<br />

Winslet. But far less known is the company<br />

that produces the coveted bronze<br />

deer: the family owned company Strassacker<br />

from Süßen near Stuttgart. Since<br />

it was founded in 1919, the company<br />

has evolved from the manufacture of<br />

pasta machines and everyday objects to<br />

the production of numerous precious<br />

artworks. The company has made a<br />

name for itself especially in the art<br />

industry and is now a well-known<br />

player. Their customers include world<br />

renowned contemporary artists, who<br />

rely on the Strassackers’ specialist expertise.<br />

Digital model creation at Strassacker<br />

While traditional production<br />

methods have characterized the creation<br />

of works of art to date, today there<br />

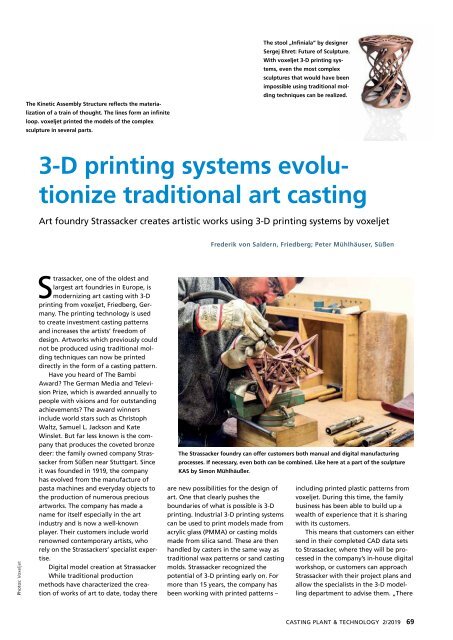

The Strassacker foundry can offer customers both manual and digital manufacturing<br />

processes. If necessary, even both can be combined. Like here at a part of the sculpture<br />

KAS by Simon Mühlhäußer.<br />

are new possibilities for the design of<br />

art. One that clearly pushes the<br />

boundaries of what is possible is 3-D<br />

printing. Industrial 3-D printing systems<br />

can be used to print models made from<br />

acrylic glass (PMMA) or casting molds<br />

made from silica sand. These are then<br />

handled by casters in the same way as<br />

traditional wax patterns or sand casting<br />

molds. Strassacker recognized the<br />

potential of 3-D printing early on. For<br />

more than 15 years, the company has<br />

been working with printed patterns –<br />

including printed plastic patterns from<br />

voxeljet. During this time, the family<br />

business has been able to build up a<br />

wealth of experience that it is sharing<br />

with its customers.<br />

This means that customers can either<br />

send in their completed CAD data sets<br />

to Strassacker, where they will be processed<br />

in the company’s in-house digital<br />

workshop, or customers can approach<br />

Strassacker with their project plans and<br />

allow the specialists in the 3-D modelling<br />

department to advise them. „There<br />

CASTING PLANT & TECHNOLOGY 2/<strong>2019</strong> 69