Issue 06/2018

bioplasticsMAGAZINE_1806

bioplasticsMAGAZINE_1806

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

From Science & Research<br />

allocation of 30 % and shows land use ranges for PLA capacity<br />

in 2017 from 75,000 hectares down to 38,000 hectares, if another<br />

source of feedstock (sugar cane) would be used.<br />

Summarizing, having single changes in fluctuations and raw<br />

material yield assumptions by each, results in a range between<br />

38,000 and almost 115,000 hectares of land, which is necessary to<br />

produce exactly the same amount of PLA.<br />

Looking at different approaches to feedstock yield and how<br />

it affects land use calculation of recent PLA capacities, there is<br />

a tremendous variation in results to be found. By the means of<br />

feedstock yields, land use ranges from -30 % to +30 % and using<br />

another feedstock source varies results up to -57 % compared to<br />

the base calculation.<br />

Thus, results of land use calculations can range as high as the<br />

amount and range of possible impact factors. This is to be kept in<br />

mind, if not only one but two or more impact factors at the same<br />

time are applied, which will multiply and lead to further increased<br />

ranges. Accumulating all ‘best case’ factors in this scenario would<br />

correspond to a theoretical land use of 25,000 hectares of PLA (-76<br />

% against base calculation).<br />

Now, how do we calculate accurately? Concerning deviations<br />

in results due to differing impact factors and also keeping in<br />

mind, that there is no ‚common sense‘ cut-off-rule for renewable<br />

feedstocks (not even in life cycle assessments), there is still more<br />

work needed on this topic. The shown examples could help to<br />

assess land use of bioplastics in a more realistic approach but as<br />

all data gathered by IfBB is openly accessible, further adaptations<br />

to the calculation of land use can be made individually, if needed.<br />

At this point, it should be mentioned that, despite the negligible<br />

amount of land use, even without a more realistic approach of<br />

calculation, there is no reason for the industry to rest on it. The<br />

pressure on agricultural land in the coming decades due to the<br />

growing world population, the loss and erosion of cultivated land<br />

will increase, and thus bioplastics will not be able to escape<br />

discussion.<br />

But there is a major advantage here: The development of<br />

bioprocessing technology increases the possibility of large-scale<br />

use of alternative renewable raw materials, which can be grown<br />

on barren soils, as well as arising new building blocks and the<br />

decomposition of organic waste streams as the starting point for<br />

the (re-)synthesis of biobased polymers is a foreseeable future.<br />

However, the primary goal for all biobased plastics, as well as<br />

for the plastics industry as a whole, should be to create intelligent<br />

material cycles and to achieve higher recycling rates. If the need<br />

for virgin material was to be reduced effectively, fewer resources<br />

would be needed to keep the plastic circle rolling. Saving raw<br />

materials could also be a way to keep the land use impact of<br />

bioplastics on a low level, when the emerging trend steadies or<br />

increases in the near future, to produce larger quantities of usually<br />

petro-based plastics from now available biobased building blocks<br />

(drop-ins).<br />

More information can be found in IfBB’s annualy updated<br />

publication of Biopolymers. Facts and statistics. It can be<br />

downloaded for free at: bit.ly/factsandstatistics<br />

www.ifbb-hannover.de<br />

Table 1<br />

Material group Producer To tal annual<br />

capacity<br />

[t]<br />

Calculations<br />

PLA<br />

A<br />

B<br />

C<br />

Land use<br />

factor<br />

[ha / t]<br />

Multiplication<br />

Equals<br />

To tal annual<br />

land use<br />

[ha]<br />

240,000 0.368 88,300<br />

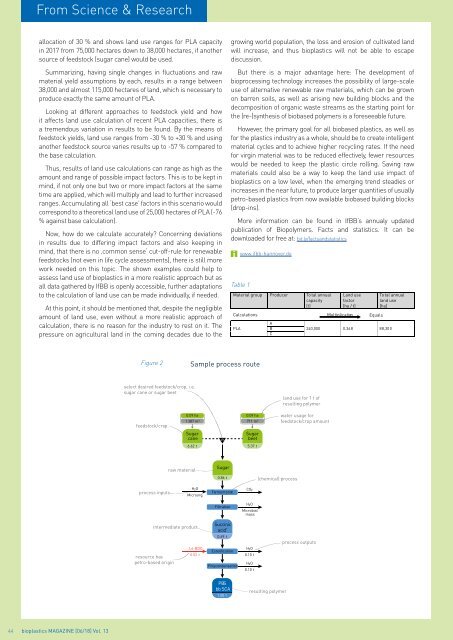

Figure 2<br />

Sample process route<br />

select desired feedstock/crop, i.e.<br />

sugar cane or sugar beet<br />

land use for 1 t of<br />

resulting polymer<br />

feedstock/crop<br />

0.09 ha<br />

1 387 m³<br />

Sugar<br />

cane<br />

6.62 t<br />

or<br />

0.09 ha<br />

711 m³<br />

Sugar<br />

beet<br />

5.37 t<br />

water usage for<br />

feedstock/crop amount<br />

raw material<br />

Sugar<br />

0.86 t<br />

(chemical) process<br />

process inputs<br />

H2O<br />

Microorg.<br />

Fermentation<br />

CO2<br />

Filtration<br />

H2O<br />

Microbial<br />

mass<br />

intermediate product<br />

resource has<br />

petro-based origin<br />

1,4-BDO<br />

0.52 t<br />

Succinic<br />

acid *<br />

0.69 t<br />

Esterification<br />

Polycondensation<br />

H2O<br />

0.10 t<br />

H2O<br />

0.10 t<br />

process outputs<br />

PBS<br />

bb SCA<br />

1.00 t<br />

resulting polymer<br />

44 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13