Issue 04/2018

bioplasticsMAGAZINE_1804

bioplasticsMAGAZINE_1804

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Coffee capsules & pods<br />

Bio-PBS to<br />

increase<br />

benefits<br />

of PLA coffee<br />

capsules<br />

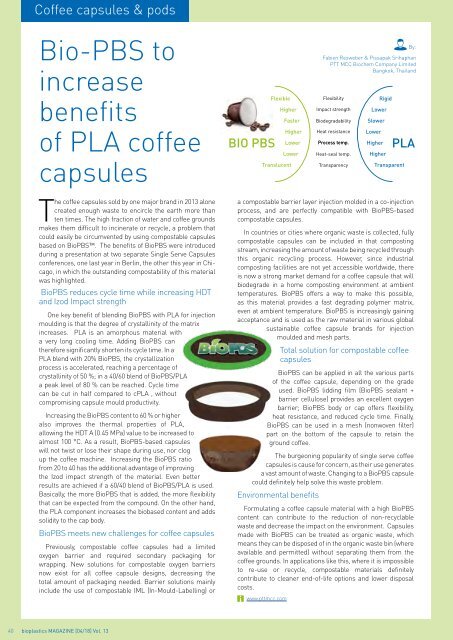

BIO PBS<br />

Flexible<br />

Higher<br />

Faster<br />

Translucent<br />

Higher<br />

Lower<br />

Lower<br />

By:<br />

Fabien Resweber & Pissapak Srihaphan<br />

PTT MCC Biochem Company Limited<br />

Bangkok, Thailand<br />

Flexibility<br />

Impact strength<br />

Biodegradability<br />

Heat resistance<br />

Process temp.<br />

Heat-seal temp.<br />

Transparency<br />

Rigid<br />

Lower<br />

Slower<br />

Lower<br />

Higher<br />

Higher<br />

PLA<br />

Transparent<br />

The coffee capsules sold by one major brand in 2013 alone<br />

created enough waste to encircle the earth more than<br />

ten times. The high fraction of water and coffee grounds<br />

makes them difficult to incinerate or recycle, a problem that<br />

could easily be circumvented by using compostable capsules<br />

based on BioPBS. The benefits of BioPBS were introduced<br />

during a presentation at two separate Single Serve Capsules<br />

conferences, one last year in Berlin, the other this year in Chicago,<br />

in which the outstanding compostability of this material<br />

was highlighted.<br />

BioPBS reduces cycle time while increasing HDT<br />

and Izod Impact strength<br />

One key benefit of blending BioPBS with PLA for injection<br />

moulding is that the degree of crystallinity of the matrix<br />

increases. PLA is an amorphous material with<br />

a very long cooling time. Adding BioPBS can<br />

therefore significantly shorten its cycle time. In a<br />

PLA blend with 20% BioPBS, the crystallization<br />

process is accelerated, reaching a percentage of<br />

crystallinity of 50 %; in a 40/60 blend of BioPBS/PLA<br />

a peak level of 80 % can be reached. Cycle time<br />

can be cut in half compared to cPLA , without<br />

compromising capsule mould productivity.<br />

Increasing the BioPBS content to 60 % or higher<br />

also improves the thermal properties of PLA,<br />

allowing the HDT A (0.45 MPa) value to be increased to<br />

almost 100 °C. As a result, BioPBS-based capsules<br />

will not twist or lose their shape during use, nor clog<br />

up the coffee machine. Increasing the BioPBS ratio<br />

from 20 to 40 has the additional advantage of improving<br />

the Izod impact strength of the material. Even better<br />

results are achieved if a 60/40 blend of BioPBS/PLA is used.<br />

Basically, the more BioPBS that is added, the more flexibility<br />

that can be expected from the compound. On the other hand,<br />

the PLA component increases the biobased content and adds<br />

solidity to the cap body.<br />

BioPBS meets new challenges for coffee capsules<br />

Previously, compostable coffee capsules had a limited<br />

oxygen barrier and required secondary packaging for<br />

wrapping. New solutions for compostable oxygen barriers<br />

now exist for all coffee capsule designs, decreasing the<br />

total amount of packaging needed. Barrier solutions mainly<br />

include the use of compostable IML (In-Mould-Labelling) or<br />

a compostable barrier layer injection molded in a co-injection<br />

process, and are perfectly compatible with BioPBS-based<br />

compostable capsules.<br />

In countries or cities where organic waste is collected, fully<br />

compostable capsules can be included in that composting<br />

stream, increasing the amount of waste being recycled through<br />

this organic recycling process. However, since industrial<br />

composting facilities are not yet accessible worldwide, there<br />

is now a strong market demand for a coffee capsule that will<br />

biodegrade in a home composting environment at ambient<br />

temperatures. BioPBS offers a way to make this possible,<br />

as this material provides a fast degrading polymer matrix,<br />

even at ambient temperature. BioPBS is increasingly gaining<br />

acceptance and is used as the raw material in various global<br />

sustainable coffee capsule brands for injection<br />

moulded and mesh parts.<br />

Total solution for compostable coffee<br />

capsules<br />

BioPBS can be applied in all the various parts<br />

of the coffee capsule, depending on the grade<br />

used. BioPBS lidding film (BioPBS sealant +<br />

barrier cellulose) provides an excellent oxygen<br />

barrier; BioPBS body or cap offers flexibility,<br />

heat resistance, and reduced cycle time. Finally,<br />

BioPBS can be used in a mesh (nonwoven filter)<br />

part on the bottom of the capsule to retain the<br />

ground coffee.<br />

The burgeoning popularity of single serve coffee<br />

capsules is cause for concern, as their use generates<br />

a vast amount of waste. Changing to a BioPBS capsule<br />

could definitely help solve this waste problem.<br />

Environmental benefits<br />

Formulating a coffee capsule material with a high BioPBS<br />

content can contribute to the reduction of non-recyclable<br />

waste and decrease the impact on the environment. Capsules<br />

made with BioPBS can be treated as organic waste, which<br />

means they can be disposed of in the organic waste bin (where<br />

available and permitted) without separating them from the<br />

coffee grounds. In applications like this, where it is impossible<br />

to re-use or recycle, compostable materials definitely<br />

contribute to cleaner end-of-life options and lower disposal<br />

costs.<br />

www.pttmcc.com<br />

40 bioplastics MAGAZINE [<strong>04</strong>/18] Vol. 13