Fuel cells and electrolysers in future energy systems - VBN

Fuel cells and electrolysers in future energy systems - VBN

Fuel cells and electrolysers in future energy systems - VBN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

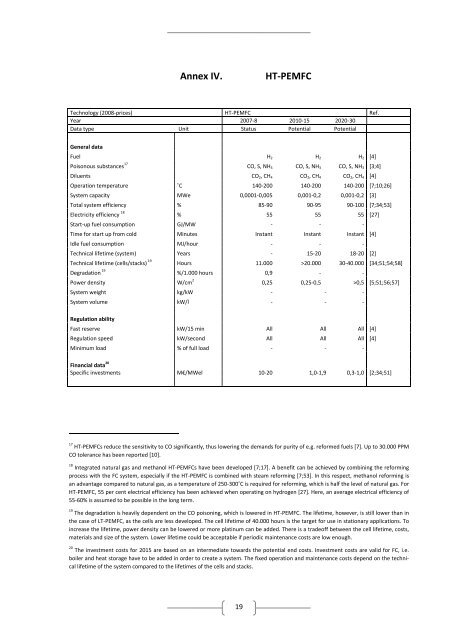

Annex IV. HT‐PEMFC<br />

Technology (2008‐prices) HT‐PEMFC Ref.<br />

Year 2007‐8 2010‐15 2020‐30<br />

Data type Unit Status Potential Potential<br />

General data<br />

<strong>Fuel</strong> H2 H2 H2 [4]<br />

Poisonous substances 17 CO, S, NH3 CO, S, NH3 CO, S, NH3 [3;4]<br />

Diluents CO2, CH4 CO2, CH4 CO2, CH4 [4]<br />

Operation temperature ˚C 140‐200 140‐200 140‐200 [7;10;26]<br />

System capacity MWe 0,0001‐0,005 0,001‐0,2 0,001‐0,2 [3]<br />

Total system efficiency % 85‐90 90‐95 90‐100 [7;34;53]<br />

Electricity efficiency 18 % 55 55 55 [27]<br />

Start‐up fuel consumption GJ/MW ‐ ‐ ‐<br />

Time for start up from cold M<strong>in</strong>utes Instant Instant Instant [4]<br />

Idle fuel consumption MJ/hour ‐ ‐ ‐<br />

Technical lifetime (system) Years ‐ 15‐20 18‐20 [2]<br />

Technical lifetime (<strong>cells</strong>/stacks) 19 Hours 11.000 >20.000 30‐40.000 [34;51;54;58]<br />

Degradation 19<br />

%/1.000 hours 0,9 ‐ ‐<br />

Power density W/cm 2 0,25 0,25‐0,5 >0,5 [5;51;56;57]<br />

System weight kg/kW ‐ ‐ ‐<br />

System volume kW/l ‐ ‐ ‐<br />

Regulation ability<br />

Fast reserve kW/15 m<strong>in</strong> All All All [4]<br />

Regulation speed kW/second All All All [4]<br />

M<strong>in</strong>imum load % of full load ‐ ‐ ‐<br />

F<strong>in</strong>ancial data 20<br />

Specific <strong>in</strong>vestments M€/MWel 10‐20 1,0‐1,9 0,3‐1,0 [2;34;51]<br />

17<br />

HT‐PEMFCs reduce the sensitivity to CO significantly, thus lower<strong>in</strong>g the dem<strong>and</strong>s for purity of e.g. reformed fuels [7]. Up to 30.000 PPM<br />

CO tolerance has been reported [10].<br />

18 Integrated natural gas <strong>and</strong> methanol HT‐PEMFCs have been developed [7;17]. A benefit can be achieved by comb<strong>in</strong><strong>in</strong>g the reform<strong>in</strong>g<br />

process with the FC system, especially if the HT‐PEMFC is comb<strong>in</strong>ed with steam reform<strong>in</strong>g [7;53]. In this respect, methanol reform<strong>in</strong>g is<br />

an advantage compared to natural gas, as a temperature of 250‐300˚C is required for reform<strong>in</strong>g, which is half the level of natural gas. For<br />

HT‐PEMFC, 55 per cent electrical efficiency has been achieved when operat<strong>in</strong>g on hydrogen [27]. Here, an average electrical efficiency of<br />

55‐60% is assumed to be possible <strong>in</strong> the long term.<br />

19 The degradation is heavily dependent on the CO poison<strong>in</strong>g, which is lowered <strong>in</strong> HT‐PEMFC. The lifetime, however, is still lower than <strong>in</strong><br />

the case of LT‐PEMFC, as the <strong>cells</strong> are less developed. The cell lifetime of 40.000 hours is the target for use <strong>in</strong> stationary applications. To<br />

<strong>in</strong>crease the lifetime, power density can be lowered or more plat<strong>in</strong>um can be added. There is a tradeoff between the cell lifetime, costs,<br />

materials <strong>and</strong> size of the system. Lower lifetime could be acceptable if periodic ma<strong>in</strong>tenance costs are low enough.<br />

20 The <strong>in</strong>vestment costs for 2015 are based on an <strong>in</strong>termediate towards the potential end costs. Investment costs are valid for FC, i.e.<br />

boiler <strong>and</strong> heat storage have to be added <strong>in</strong> order to create a system. The fixed operation <strong>and</strong> ma<strong>in</strong>tenance costs depend on the techni‐<br />

cal lifetime of the system compared to the lifetimes of the <strong>cells</strong> <strong>and</strong> stacks.<br />

19