- Page 1: Fuel cells and electrolysers in fut

- Page 5 and 6: Tilegnet mine forældre Karl Kristi

- Page 7 and 8: Abstract Efficient fuel cells and e

- Page 9 and 10: Dansk resumé Effektive brændselsc

- Page 11 and 12: Contents ABSTRACT .................

- Page 13: Appendices I. B. V. Mathiesen and M

- Page 16 and 17: In this dissertation, fuel cells an

- Page 18 and 19: Nomenclature Power generation and r

- Page 20 and 21: Fuel cells and electrolysers have t

- Page 22 and 23: In December 2006, a plan for how an

- Page 24 and 25: a) Fuel 107 units b) Fuel 87 units

- Page 26 and 27: In the current energy system, elect

- Page 29 and 30: 2 The energy system analysis method

- Page 31 and 32: taxes. Output consists of annual en

- Page 33 and 34: 3 Reference systems and the design

- Page 35 and 36: the IDA 2030 system, and, in an upd

- Page 37: gies to improve the integration of

- Page 40 and 41: Fuel cells AFC PEMFC PAFC MCFC SOFC

- Page 42 and 43: PEMFCs are characterised by a rathe

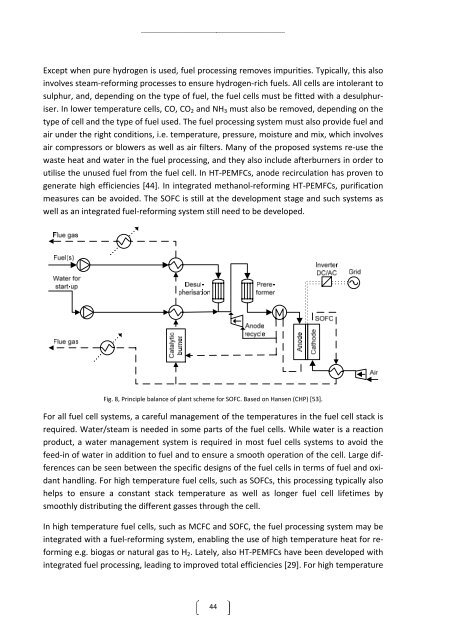

- Page 44 and 45: tion time in portable devices [25].

- Page 48 and 49: they supply. In transport applicati

- Page 50 and 51: Thus, when in operation, all types

- Page 52 and 53: CHP, and under four ancillary servi

- Page 54 and 55: Grid‐stabilising plants 30 per ce

- Page 56 and 57: In the IDA 2030 energy system, a sh

- Page 58 and 59: PES excl. wind power (TWh) PES excl

- Page 61 and 62: 6 Applications of solid oxide fuel

- Page 63 and 64: tion of power plants and improve th

- Page 65 and 66: hydrogen Central and Local FC‐CHP

- Page 67 and 68: The combinations of seven different

- Page 69 and 70: when fuel prices are high, especial

- Page 71 and 72: 6.4 Socio‐economic consequences I

- Page 73 and 74: 7 Individual household heating syst

- Page 75 and 76: kW/kW‐average 3 2 1 0 Heat Demand

- Page 77 and 78: Fig. 19, Annual fuel consumption of

- Page 79 and 80: Fuel (TWh/year) 14 12 10 8 6 4 2 0

- Page 81 and 82: M. EUR/year 800 700 600 500 400 300

- Page 83 and 84: Fuel (TWh/year) 18 16 14 12 10 8 6

- Page 85 and 86: d) Compared with other fossil fuel

- Page 87 and 88: systems are installed, such low tax

- Page 89: given heat production. A system is

- Page 92 and 93: energy systems in the coming years,

- Page 94 and 95: The second of the two types of ener

- Page 96 and 97:

Wind power Fuel Power plant CHP Boi

- Page 98 and 99:

has been used for identifying the n

- Page 100 and 101:

In Fig. 37, the effects of using th

- Page 102 and 103:

In the energy system analyses, HP p

- Page 104 and 105:

M€/TWh fuel saved 120 100 80 60 4

- Page 106 and 107:

For all alternatives, doubling the

- Page 109 and 110:

9 Life cycle screening of solid oxi

- Page 111 and 112:

chromium alloy used in the intercon

- Page 113:

In terms of primary energy consumpt

- Page 116 and 117:

ures on the path towards future 100

- Page 118 and 119:

plemented first. The socio‐econom

- Page 120 and 121:

socio‐economic calculations)," Da

- Page 122 and 123:

[40] M. C. Tucker, G. Y. Lau, C. P.

- Page 124 and 125:

[69] H. Lund, "Excess electricity d

- Page 127:

Appendix I 3

- Page 130 and 131:

2 Fuel cell types In most countries

- Page 132 and 133:

transport or smaller devices. DMFCs

- Page 134 and 135:

combined with the water management

- Page 136 and 137:

While interconnectors diffuse the g

- Page 138 and 139:

the systems are less sensitive to p

- Page 140 and 141:

Annex I. AFC Technology (2008‐pri

- Page 142 and 143:

Annex III. LT‐PEMFC Technology (2

- Page 144 and 145:

Annex V. MCFC Technology MCFC‐sys

- Page 146 and 147:

References [1] B. V. Mathiesen and

- Page 148 and 149:

[32] J. R. Selman, "Molten‐salt f

- Page 150 and 151:

[64] L. Blum, H. P. Buchkremer, S.

- Page 153 and 154:

Abstract Solid oxide fuel cells and

- Page 155 and 156:

West Denmark Norway Germany 31 Swed

- Page 157 and 158:

2 Ancillary service requirements An

- Page 159 and 160:

have been identified. For SOFCs, me

- Page 161 and 162:

As a reference for the analyses, a

- Page 163 and 164:

• Wind turbines and locally dispa

- Page 165 and 166:

In the first ancillary service scen

- Page 167 and 168:

10 Acknowledgements This paper is p

- Page 169:

[34] M. C. Tucker, G. Y. Lau, C. P.

- Page 173 and 174:

Research Signpost 37/661 (2), Fort

- Page 175 and 176:

Energy system analysis of fuel cell

- Page 177 and 178:

Energy system analysis of fuel cell

- Page 179 and 180:

Energy system analysis of fuel cell

- Page 181 and 182:

Energy system analysis of fuel cell

- Page 183 and 184:

Energy system analysis of fuel cell

- Page 185 and 186:

Energy system analysis of fuel cell

- Page 187 and 188:

Energy system analysis of fuel cell

- Page 189:

Energy system analysis of fuel cell

- Page 193 and 194:

Solid oxide fuel cells in renewable

- Page 195 and 196:

now, the changes in the Danish ener

- Page 197 and 198:

In the next step, a market exchange

- Page 199 and 200:

Extensive investments have to be ma

- Page 201 and 202:

2.4 Costs of fuels, fuel handling,

- Page 203 and 204:

Input: BAU 2030 Electricity system

- Page 205 and 206:

potential for producing heat in FC

- Page 207 and 208:

cies do not increase due to larger

- Page 209 and 210:

In dry years, FC‐CHPs generate pr

- Page 211 and 212:

4 Conclusion SOFC can improve the f

- Page 213:

[23] Danish Energy Authority, "Frem

- Page 217 and 218:

Comparative energy system analysis

- Page 219 and 220:

2 Methodology In the methodology, t

- Page 221 and 222:

to fuel at households of 72 per cen

- Page 223 and 224:

listed in table 5 are from the Dani

- Page 225 and 226:

Fig. 4, Annual fuel consumption of

- Page 227 and 228:

enables a heat supply for at least

- Page 229 and 230:

The COP of both HP systems have to

- Page 231 and 232:

operated simultaneously; that the C

- Page 233 and 234:

The HP systems analysed for 300,000

- Page 235 and 236:

M. EUR/year 1,300 1,100 900 700 500

- Page 237:

[11] B. V. Mathiesen and H. Lund, "

- Page 241 and 242:

Comparative analyses of seven techn

- Page 243 and 244:

energy system analysed. Outputs are

- Page 245 and 246:

illustrates the excess electricity

- Page 247 and 248:

Input: DEA 2030 (market) 123 Refere

- Page 249 and 250:

Wind power Fuel Power plant CHP Boi

- Page 251 and 252:

of driving at full capacity. The di

- Page 253 and 254:

Open energy system, 25 TWh annual w

- Page 255 and 256:

Marginal PES excl. wind (TWh) 0,0 -

- Page 257 and 258:

educes excess production and fuel s

- Page 259 and 260:

M€/TWh fuel saved 120 100 80 60 4

- Page 261 and 262:

[8] M. Little, M. Thomson, and D. I

- Page 263:

[37] Danish Energy Authority, Elkra

- Page 267 and 268:

Long term perspective for balancing

- Page 269 and 270:

Contents 1 Technology Description .

- Page 271 and 272:

7.2.1 Fuel cell types In Table 7-2

- Page 273 and 274:

In the SOFCs the electrolyte allows

- Page 275 and 276:

In the same energy system SOFC CHP

- Page 277 and 278:

400$/kW before 2015 also for SOFC s

- Page 279 and 280:

unning temperature is lowered to 55

- Page 281:

[12] B. V. Mathiesen and H. Lund, "

- Page 285 and 286:

Abstract Integrated transport and r

- Page 287 and 288:

phase. The detailed energy system a

- Page 289 and 290:

The increase in the international a

- Page 291 and 292:

2030, this results in 28.56 PJ net

- Page 293 and 294:

ate to 6 per cent. The result is th

- Page 295:

Appendix IX 171

- Page 298 and 299:

2 The design of 100% renewable ener

- Page 300 and 301:

4 documentation of the model can be

- Page 302 and 303:

6 1.000 900 800 700 600 500 400 300

- Page 304 and 305:

8 combined in order to reach the ta

- Page 307 and 308:

Uncertainties related to the identi

- Page 309 and 310:

tion of one marginal technology is

- Page 311 and 312:

policies for changes and a projecti

- Page 313 and 314:

The policy from 1996 [24] built on

- Page 315 and 316:

tial LCA studies should include sev

- Page 317 and 318:

6 Case study of the affected electr

- Page 319 and 320:

adding waste to the BAU energy syst

- Page 321 and 322:

fected; thus, reinvestments are aff

- Page 323 and 324:

Appendix A LCA‐Study Miljømæssi

- Page 325:

LCA‐Study LCA of Danish fish prod

- Page 328 and 329:

[16] G. Finnveden, J. Johansson, P.

- Page 330:

[46] N. Mattsson, T. Unger, and T.