Fuel cells and electrolysers in future energy systems - VBN

Fuel cells and electrolysers in future energy systems - VBN

Fuel cells and electrolysers in future energy systems - VBN

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

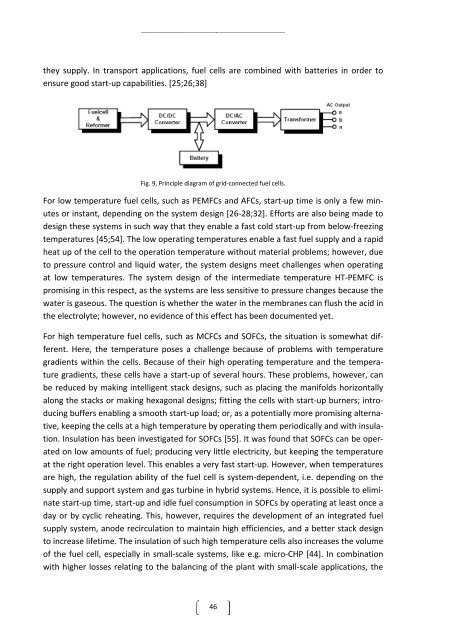

they supply. In transport applications, fuel <strong>cells</strong> are comb<strong>in</strong>ed with batteries <strong>in</strong> order to<br />

ensure good start‐up capabilities. [25;26;38]<br />

Fig. 9, Pr<strong>in</strong>ciple diagram of grid‐connected fuel <strong>cells</strong>.<br />

For low temperature fuel <strong>cells</strong>, such as PEMFCs <strong>and</strong> AFCs, start‐up time is only a few m<strong>in</strong>‐<br />

utes or <strong>in</strong>stant, depend<strong>in</strong>g on the system design [26‐28;32]. Efforts are also be<strong>in</strong>g made to<br />

design these <strong>systems</strong> <strong>in</strong> such way that they enable a fast cold start‐up from below‐freez<strong>in</strong>g<br />

temperatures [45;54]. The low operat<strong>in</strong>g temperatures enable a fast fuel supply <strong>and</strong> a rapid<br />

heat up of the cell to the operation temperature without material problems; however, due<br />

to pressure control <strong>and</strong> liquid water, the system designs meet challenges when operat<strong>in</strong>g<br />

at low temperatures. The system design of the <strong>in</strong>termediate temperature HT‐PEMFC is<br />

promis<strong>in</strong>g <strong>in</strong> this respect, as the <strong>systems</strong> are less sensitive to pressure changes because the<br />

water is gaseous. The question is whether the water <strong>in</strong> the membranes can flush the acid <strong>in</strong><br />

the electrolyte; however, no evidence of this effect has been documented yet.<br />

For high temperature fuel <strong>cells</strong>, such as MCFCs <strong>and</strong> SOFCs, the situation is somewhat dif‐<br />

ferent. Here, the temperature poses a challenge because of problems with temperature<br />

gradients with<strong>in</strong> the <strong>cells</strong>. Because of their high operat<strong>in</strong>g temperature <strong>and</strong> the tempera‐<br />

ture gradients, these <strong>cells</strong> have a start‐up of several hours. These problems, however, can<br />

be reduced by mak<strong>in</strong>g <strong>in</strong>telligent stack designs, such as plac<strong>in</strong>g the manifolds horizontally<br />

along the stacks or mak<strong>in</strong>g hexagonal designs; fitt<strong>in</strong>g the <strong>cells</strong> with start‐up burners; <strong>in</strong>tro‐<br />

duc<strong>in</strong>g buffers enabl<strong>in</strong>g a smooth start‐up load; or, as a potentially more promis<strong>in</strong>g alterna‐<br />

tive, keep<strong>in</strong>g the <strong>cells</strong> at a high temperature by operat<strong>in</strong>g them periodically <strong>and</strong> with <strong>in</strong>sula‐<br />

tion. Insulation has been <strong>in</strong>vestigated for SOFCs [55]. It was found that SOFCs can be oper‐<br />

ated on low amounts of fuel; produc<strong>in</strong>g very little electricity, but keep<strong>in</strong>g the temperature<br />

at the right operation level. This enables a very fast start‐up. However, when temperatures<br />

are high, the regulation ability of the fuel cell is system‐dependent, i.e. depend<strong>in</strong>g on the<br />

supply <strong>and</strong> support system <strong>and</strong> gas turb<strong>in</strong>e <strong>in</strong> hybrid <strong>systems</strong>. Hence, it is possible to elimi‐<br />

nate start‐up time, start‐up <strong>and</strong> idle fuel consumption <strong>in</strong> SOFCs by operat<strong>in</strong>g at least once a<br />

day or by cyclic reheat<strong>in</strong>g. This, however, requires the development of an <strong>in</strong>tegrated fuel<br />

supply system, anode recirculation to ma<strong>in</strong>ta<strong>in</strong> high efficiencies, <strong>and</strong> a better stack design<br />

to <strong>in</strong>crease lifetime. The <strong>in</strong>sulation of such high temperature <strong>cells</strong> also <strong>in</strong>creases the volume<br />

of the fuel cell, especially <strong>in</strong> small‐scale <strong>systems</strong>, like e.g. micro‐CHP [44]. In comb<strong>in</strong>ation<br />

with higher losses relat<strong>in</strong>g to the balanc<strong>in</strong>g of the plant with small‐scale applications, the<br />

46