issue 02/2021

Highlights: Injection Moulding Basics: Mass Balance

Highlights:

Injection Moulding

Basics: Mass Balance

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

More bio in surfing<br />

Researchers at the Fraunhofer WKI, Braunschweig, Germany, are developing the stand-up paddleboard ecoSUP with a<br />

lightweight sandwich element made from renewable raw materials. Lightweight construction materials are environmentally<br />

friendly, as less energy and fewer resources are required for transport and production. Conventional lightweight-construction<br />

materials are based on fossil and other finite resources such as metals and minerals. “We selected a stand-up paddleboard<br />

as the demonstration object for our lightweight-construction material, as it has to meet high requirements with regard to<br />

mechanical strength in combination with resistance to moisture, saltwater, and UV radiation. In the future, our new biocomposite<br />

material could be utilized not only in other watersports equipment but also in the construction of buildings, cars,<br />

ships, and trains,” explained Christoph Pöhler, Project Manager at the Fraunhofer WKI.<br />

Currently, watersports equipment, such as surfboards, is produced using petroleum-based materials such as<br />

epoxy resin, polyester resin, polyurethane, and expanded or extruded polystyrene in combination with<br />

glass and carbon-fibre fabrics. The market for glass- and carbon-fibre-reinforced plastics is<br />

also growing continuously in other economic sectors. This offers a high savings potential<br />

for finite resources.<br />

Application News<br />

“For the core of the new bio lightweight-construction material, we use recycled<br />

balsa wood and modify it accordingly. Balsa wood is used in large quantities<br />

in the rotor blades of wind turbines. At the end of the life cycle of the rotor<br />

blades, it accumulates as waste and is then burnt. We now want to give this<br />

balsa wood a longer useful life,” Pöhler explained.<br />

The researchers are also developing an outer shell made from natural-fibrereinforced<br />

bioplastics on the basis of itaconic acid. They are hereby concentrating on the<br />

application of flax fibres, as these have advantageous mechanical properties and are cultivated in<br />

Europe. AT<br />

www.wki.fraunhofer.de/en<br />

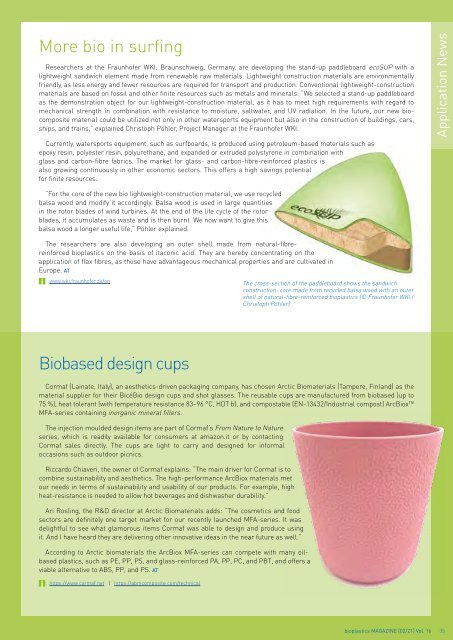

The cross-section of the paddleboard shows the sandwich<br />

construction: core made from recycled balsa wood with an outer<br />

shell of natural-fibre-reinforced bioplastics (© Fraunhofer WKI I<br />

Christoph Pöhler)<br />

Biobased design cups<br />

Cormaf (Lainate, Italy), an aesthetics-driven packaging company, has chosen Arctic Biomaterials (Tampere, Finland) as the<br />

material supplier for their BicéBio design cups and shot glasses. The reusable cups are manufactured from biobased (up to<br />

75 %), heat tolerant (with temperature resistance 83–96 °C, HDT b), and compostable (EN-13432/Industrial compost) ArcBiox TM<br />

MFA-series containing inorganic mineral fillers.<br />

The injection moulded design items are part of Cormaf’s From Nature to Nature<br />

series, which is readily available for consumers at amazon.it or by contacting<br />

Cormaf sales directly. The cups are light to carry and designed for informal<br />

occasions such as outdoor picnics.<br />

Riccardo Chiaveri, the owner of Cormaf explains: “The main driver for Cormaf is to<br />

combine sustainability and aesthetics. The high-performance ArcBiox materials met<br />

our needs in terms of sustainability and usability of our products. For example, high<br />

heat-resistance is needed to allow hot beverages and dishwasher durability.”<br />

Ari Rosling, the R&D director at Arctic Biomaterials adds: “The cosmetics and food<br />

sectors are definitely one target market for our recently launched MFA-series. It was<br />

delightful to see what glamorous items Cormaf was able to design and produce using<br />

it. And I have heard they are delivering other innovative ideas in the near future as well.”<br />

According to Arctic biomaterials the ArcBiox MFA-series can compete with many oilbased<br />

plastics, such as PE, PP, PS, and glass-reinforced PA, PP, PC, and PBT, and offers a<br />

viable alternative to ABS, PP, and PS. AT<br />

https://www.cormaf.net | https://abmcomposite.com/technical<br />

bioplastics MAGAZINE [<strong>02</strong>/21] Vol. 16 35