drinkworld Technology + Marketing 1/2022

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ZKZ 62006<br />

ISSN 1433-1594 Vol. 26 No. 1 March <strong>2022</strong> US $ 12 · € 12<br />

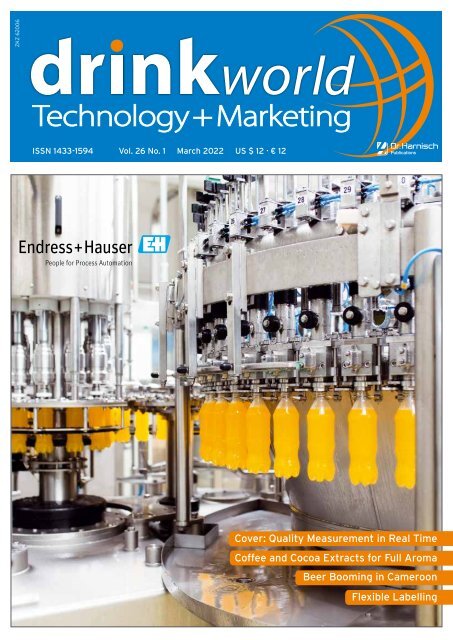

Cover: Quality Measurement in Real Time<br />

Coffee and Cocoa Extracts for Full Aroma<br />

Beer Booming in Cameroon<br />

Flexible Labelling

NEW: THE<br />

ELECTRIC STEAM<br />

GENERATOR<br />

[GENERATION E]<br />

E320MX<br />

_ EFFICIENT<br />

[CERTUSS PLUG & PLAY]<br />

_ COMPACT<br />

[SPACE-SAVING]<br />

_ MODULAR<br />

[OUTPUT 10 TO 320 KG/H]<br />

_ STRONG<br />

[MAWP UP TO 16 BAR]<br />

Visit us at Anuga FoodTec:<br />

Hall 10.1 · Stand F 069<br />

www.certuss-emx.com

Editorial<br />

Women of the World - We Salute You<br />

Every year around this time it is<br />

International Women's Day. This<br />

brings a chance to reflect and<br />

consider what benefits and riches<br />

we have in our lives, because a<br />

woman has stood up or fought for<br />

something, just because of who she<br />

is. Women represent less than 1% of<br />

written history.<br />

One day is of course not enough<br />

to do justice to the incredible work<br />

carried out by women everywhere,<br />

and especially in the world of drink<br />

technology. Here is a very small<br />

selection from spirits and from<br />

coffee to whet your appetite for<br />

more. In honour of International<br />

Women's Day the UK company The<br />

Bottle Club (www.thebottleclub.<br />

com), celebrated some of the most<br />

amazing women in history.<br />

Betsy Flanagan coined the word<br />

'cocktail' in her Yorktown tavern<br />

in the 1770s. Flanagan is said to<br />

have stirred drinks decorated with<br />

colourful rooster tails to show her<br />

support of the rebels during the<br />

English occupation of northern<br />

Virginia - dubbing the term<br />

'cocktail.' Betsy was an innovative<br />

entrepreneur, who was witty and<br />

successful, as stories of her legend<br />

are still told to this day.<br />

Raise your Margarita to Margarita<br />

Carmen Cansino herself, better<br />

known as Old Hollywood actress<br />

Rita Hayworth. Rita is said to have<br />

inspired barman Enrique Bastante<br />

Gutierez, a former cocktail champion<br />

who mixed drinks for some of the<br />

world's most famous film stars, to<br />

invent the Margarita due to her<br />

glamour and beauty. The Margarita<br />

has certainly stood the test of time<br />

and is still a favourite cocktail today.<br />

Known as the First Lady of Spirits,<br />

Joy Spence is a Jamaican chemist<br />

and master blender at Appleton<br />

Estate, becoming the first female<br />

blender in 1997. Since then, she's<br />

created many of the blends that<br />

made Appleton Estate famous. Her<br />

love, expertise and personal touch<br />

goes into each and every bottle to<br />

produce only the finest concoctions.<br />

Joy was the first, and today remains<br />

only one of three women Master<br />

Blenders in the world.<br />

Nayana Ferguson is the first black<br />

woman in the world to found a tequila<br />

company. She's a pancreatic and<br />

breast cancer survivor and cancer<br />

awareness advocate, and initially<br />

created Anteel for health reasons<br />

as she wanted to enjoy cocktails<br />

without the harmful additives.<br />

Tequila is a spirit that is made from<br />

the agave plant, so it is naturally<br />

gluten free and low in carbs, sugar<br />

and calories. Ferguson wanted to<br />

educate people on the benefits of<br />

tequila and change the stereotypical<br />

thought of what tequila is.<br />

The European Fair Trade Pioneer<br />

GEPA in Germany (www.gepa.de)<br />

has also paid tribute to women in<br />

the coffee sector. The key word<br />

Empowerment helps women to<br />

find economic independence and<br />

leadership. When women are strong,<br />

society is strong.<br />

Leiticia Vilchez is a good example<br />

of this. Through fair prices for their<br />

coffee cooperative in Peru, her<br />

parents could finance her studies<br />

Ian D. Healey<br />

Editor-in-Chief<br />

Photo: BB<br />

to become a dentist. Now she can treat<br />

and help members of the cooperative.<br />

In Honduras twelve women learned all<br />

about coffee roasting, as well as quality<br />

assurance. They can now earn more<br />

income through packaging and labelling,<br />

keeping added value at source.<br />

Evangelina Matute Vasquez is a coffee<br />

farmer who has also profited from Fair<br />

Trade. Through the sale of her organic<br />

products she has been able to improve<br />

storage, invested in transport and waste<br />

reduction facilities. "Every year I have<br />

new goals, which the cooperative helps<br />

me to meet."<br />

According to a World Fair Trade<br />

Organization study, women who are<br />

supported by their member associations<br />

have a four times higher chance to<br />

reach senior management positions<br />

than those in conventional trades.<br />

When women are strengthened, more<br />

fairness and more effectivity is found<br />

throughout society as a whole. Again,<br />

we cannot underline this enough. But<br />

International Women's Day is definitely<br />

a start.<br />

Cheers<br />

www.drink-tm.com<br />

If you like it – subscribe!<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong> 3

Contents<br />

ZKZ 62006<br />

tic<br />

Industry.<br />

ge processing plants. These high<br />

e application capability, lubricant<br />

1 safety requirements.<br />

:<br />

rade Fluid Lubricants<br />

ynthetic H1 Fluids.<br />

mended for Air Compressors,<br />

s, Gearboxes and Chains.<br />

y grades.<br />

ries:<br />

rade Synthetic Greases<br />

Calcium Sulfonate Complex Type Greases.<br />

l for a Variety of Applications.<br />

ar and Extreme Pressure Protection.<br />

SO-FG 150<br />

hetic lubricants are designed for use in<br />

ment with oil recirculating systems<br />

Registered ISO 9001<br />

95 23<br />

and ISO 50001<br />

ISSN 1433-1594 Vol. 26 No. 1 March <strong>2022</strong> US $ 12 · € 12<br />

Cover: Quality Measurement in Real Time<br />

Coffee and Cocoa Extracts for Full Aroma<br />

Beer Booming in Cameroon<br />

Flexible Labelling<br />

Issue 1 · March <strong>2022</strong><br />

A liquid analysis directly in the process with Teqwave H offers users many<br />

advantages. The device enables reduced costs because it measures differentconcentrations<br />

at the same time using only one sensor. Concentration<br />

data sets that are preinstalled make it possible to use the same sensor with<br />

noreprogramming. It is also possible to read additional parameters. Teqwave<br />

H ensures reliable processes and transparency of product quality in real<br />

time.<br />

Our cover story starts on page 6.<br />

Cover: Endress+Hauser<br />

Ingredients<br />

14 Coffee and Cocoa Extracts: Natural Products<br />

Full of Aroms<br />

16 ‘Positive Ageing’ is Driving Demand for<br />

Healthier Nutrition<br />

19 Best of Both Worlds: Vitafoods Europe Returns as<br />

a SMART event for <strong>2022</strong><br />

Processing<br />

6 In-Line Concentration Measurement<br />

in Real Time for Highest Quality<br />

24 It’s All About the Mix – for Beer Exports and<br />

Industrial Hoses<br />

28 Key Role for Quality<br />

33 New Sensors for Measuring H 2<br />

O 2<br />

and PAA<br />

Coffee and cocoa beans are highly aromatic, as anyone<br />

knows who has ever smelled the intense aroma of freshly<br />

milled coffee beans or tasted freshly made cocoa. The raw<br />

beans only develop their full aromatic effect after roasting.<br />

That’s why producers use roasted coffee beans and cocoa<br />

powder as raw materials for creating natural cocoa and<br />

coffee aromas. Full details on page 14<br />

Fast urbanization and a rapidly growing middle class are<br />

turning the African continent into a dynamic market that<br />

holds great potential. This is something international<br />

breweries especially are profiting from and where they see<br />

new opportunities. By 2025 a third of the growth in beer<br />

sales is expected to be attributable to sub-Saharan Africa.<br />

The technology is already in place. See page 28<br />

4

Contents<br />

<strong>Marketing</strong> & Trends<br />

8 Beverages Get Juicy<br />

Departments<br />

3 Editorial<br />

42 Supplier's Guide<br />

Events<br />

41 Calendar of Events<br />

Packaging<br />

34 Process Pilot Provides “Technical Safeguard” as<br />

Eckes-Granini Shifts to 100% rPET Bottles<br />

36 Speedy Response for Soaring Demand<br />

38 How the Label becomes more Sustainable and<br />

Flexible<br />

Food and beverage industry players are particularly concerned<br />

about the costs of materials and are keen to optimize their<br />

investment while increasing brand recognition. One of the<br />

leading manufacturers in the market shares their expertise to<br />

meet all labelling needs. A greater focus on sustainability and<br />

flexibility is changing the way labels are created and applied.<br />

See the full article on page 38<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong> 5

Cover Story<br />

Teqwave H<br />

In-Line Concentration Measurement in<br />

Real Time for Highest Quality<br />

The reliable smart sensor in hygienic design for permanent process control in the food and<br />

beverage industry<br />

Teqwave H enables users to analyze and<br />

monitor fluids in the food and beverage<br />

industry reliably. Applications include<br />

monitoring sugar content in fruit<br />

juices and distilled beverages or the<br />

concentration of cleaning agents. The<br />

hygienic design of Teqwave H fulfills the<br />

highest quality standards. State-of-theart<br />

algorithms and a flexible application<br />

concept guarantee optimal process<br />

control even for changing batches.<br />

A liquid analysis directly in the process<br />

with Teqwave H offers users<br />

many advantages. The device enables<br />

reducing costs because it measures<br />

different concentrations at the<br />

same time using only one sensor.<br />

Concentration data sets that are<br />

preinstalled for the most common<br />

beverages and cleaning agents make it<br />

possible to use the same sensor with<br />

no reprogramming and without any<br />

problems, even for batch changes. It<br />

is also possible to read in additional<br />

parameters, such as the acid content.<br />

Teqwave H uses these to calculate<br />

the concentration with even greater<br />

accuracy thanks to state-of-the-art<br />

algorithms. Thus, it ensures reliable<br />

processes and transparency of product<br />

quality in real time. The continuous<br />

in-line measurement means that no<br />

sampling is required. The easy-toclean<br />

full-bore design of Teqwave H<br />

guarantees that the highest hygienic<br />

standards are fulfilled.<br />

The dispersion measurement is<br />

another advantage. The common<br />

appearance of disturbance variables<br />

such as particles and gas bubbles are<br />

no longer a problem, since Teqwave H<br />

measures, displays and compensates<br />

for these disturbances and their<br />

severity directly.<br />

Teqwave H with tri-clamp process connections and transmitter with protective housing in stainless steel<br />

Concentration crucial for<br />

product quality<br />

Teqwave H is capable of measuring a wide<br />

range of measured variables that enable it<br />

to be used flexibly in various applications.<br />

In soft drink and fruit juice production,<br />

the measuring device assures product<br />

quality through its reliable determination<br />

of sugar content and invert sugar content.<br />

For production of distilled beverages, it<br />

ensures that the alcohol content remains<br />

consistent. In addition, it simultaneously<br />

measures the sugar content. When<br />

cleaning plants, bottles and kegs, Teqwave<br />

H also monitors different concentrations<br />

and it supports precise dosing of cleaning<br />

agents. If the cleaning agent needs to be<br />

changed, this can be done easily without<br />

recalibration.<br />

Hygienic design for highest<br />

quality standards<br />

Teqwave H is especially developed<br />

for hygienic applications in the food<br />

6

Cover Story<br />

and beverage industry. Its outstanding<br />

feature, in addition to the stainless-steel<br />

measuring tube, is its full-bore design.<br />

Thanks to the design without protruding<br />

parts, there are no places inside the<br />

measuring tube where material can<br />

accumulate. Another benefit is that<br />

there is no pressure loss, making it<br />

possible to save on energy costs.<br />

Plug-and-play thanks to<br />

preinstalled data sets<br />

Teqwave H offers a wide variety of<br />

preinstalled product-specific data sets for<br />

concentration measurement, which allow<br />

the calibration usually repeated after<br />

batch change to be omitted. The users can<br />

adapt these data sets to their product as<br />

needed to further increase the accuracy<br />

of concentration measurements. This<br />

means that users with a wide product<br />

range need just one measuring device<br />

for a broad range of applications. This is<br />

particularly helpful when one production<br />

line is being used to manufacture the<br />

entire product range in various batches.<br />

Unique function for gas bubble<br />

and particle detection<br />

In many processes, dispersion typically<br />

occurs in the form of gas bubbles or<br />

particles that can interfere with the<br />

measuring signals. To support stable<br />

process control, Teqwave enables users<br />

to detect such disturbance variables,<br />

evaluate their severity and compensate<br />

for them to achieve continuous<br />

accurate measurement. The device<br />

warns the user when the disturbance<br />

variables affect measuring accuracy.<br />

This guarantees maximum reliability<br />

and provides users with even greater<br />

transparency in their processes.<br />

• Continuous monitoring of disturbance<br />

variables directly in the process<br />

• Immediate notice message if<br />

the disturbance variables affect<br />

measuring accuracy<br />

• Reliable dispersion measurement;<br />

reacts exclusively to gas bubbles,<br />

particles, or two-phase mixtures (e.g.<br />

with emulsion formation)<br />

• Targeted reaction to error signals in<br />

the production process, such as for<br />

contamination or leaks.<br />

Transmitter for seamless<br />

system integration<br />

Teqwave H is available with a transmitter<br />

in a remote version that can be optionally<br />

ordered with a stainless-steel protective<br />

housing. Teqwave leaves nothing to<br />

be desired in terms of performance<br />

and accuracy. Teqwave simultaneously<br />

records multiple measured values that<br />

are essential for process control, such<br />

as concentrations, speed of sound,<br />

acoustic density, and temperature in<br />

many different fluids, and then forwards<br />

them to the process control systems.<br />

Complete access to all measurement<br />

data is possible at any time – by using<br />

conventional 4–20 mA or thanks to digital<br />

data transmission via Modbus TCP.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

7

<strong>Marketing</strong><br />

Beverages Get Juicy<br />

by DONNA BERRY<br />

A lot has changed in the juice beverage<br />

business in the past 25 years, much<br />

out of necessity. The category needed<br />

a makeover to stay competitive and<br />

keep consumers drinking juice, as many<br />

learned to think of fruit and vegetable<br />

extractions as concentrated sources of<br />

empty-calorie sugars.<br />

Today juices are being used in<br />

combination with other fluids and<br />

better-for-you ingredients to improve<br />

their nutritional value. Many emphasize<br />

their sourcing while others promote the<br />

juicing process. In some instances, the<br />

juice serves as a flavor or sweetening<br />

ingredient to a different base beverage.<br />

It’s even getting boozed up.<br />

Molson Coors Beverage Company, for<br />

example, is expanding its Vizzy Hard<br />

Seltzer portfolio with the introduction<br />

of Vizzy Mimosa Hard Seltzer. Inspired<br />

by the mimosa cocktail, the hard seltzer<br />

is made with real orange juice, mimosainspired<br />

flavors and antioxidant vitamin<br />

C from the acerola fruit. The new product<br />

is available in four different flavors:<br />

Peach Orange, Pineapple Orange,<br />

Pomegranate Orange and Strawberry<br />

Orange.<br />

Fruit juice helps “naturally” sweeten<br />

caffeinated beverages, such as Starbucks<br />

Refreshers, where the caffeine comes<br />

from green coffee extract. There’s also<br />

MTN DEW KICKSTART from PepsiCo,<br />

which is a fusion of Mountain Dew soda,<br />

real fruit juice and a kick of caffeine.<br />

Both lines have been around for<br />

almost a decade, with flavors coming<br />

and going. It’s all about switching up<br />

the juice component. Some of the<br />

trendy offerings in the KICKSTART line<br />

now include Blood Orange, Blueberry<br />

Pomegranate and Watermelon.<br />

Watermelon juice has been gaining<br />

traction among health aficionados for<br />

its high antioxidant (lycopene) and<br />

electrolyte (potassium) content. In<br />

the US, Frey Farms—one of the largest<br />

processors of watermelon juice in the<br />

country--is responding to growing<br />

interest in watermelon juice through<br />

a major expansion to its cold-pressed<br />

processing center. It will yield 6,000<br />

gallons of cold-pressed, unpasteurized<br />

watermelon juice per day. Each<br />

watermelon undergoes a proprietary<br />

process that uses minimal processing<br />

techniques to cold extract the juice and<br />

chill it to near freezing within minutes.<br />

This innovative process helps to<br />

maintain superior flavor while retaining<br />

its natural color, as well as nutrients. In<br />

addition to the original watermelon juice,<br />

the company now offers a watermelon<br />

juice and coconut water blend, with<br />

more concepts in the works.<br />

Cold-press processing is a key to many<br />

of the newer 100% juice products<br />

entering the marketplace. The more<br />

traditional method of extracting liquid<br />

from fruits and vegetables is centrifugal<br />

juicing. This is where fast-spinning<br />

blades expel the juices, as compared to<br />

the slow pulverizer with hydraulic press<br />

used in cold-pressed technology. Most<br />

of the bottled juice brands driving sales<br />

in the category fall into the category<br />

of cold pressed, with many of these<br />

juices further undergoing high-pressure<br />

processing (HPP) in order to obtain<br />

about a 30-day refrigerated shelf life.<br />

The HPP technology uses very high<br />

pressure and no heat to kill potentially<br />

harmful microorganisms to ensure a<br />

safe and good-tasting product.<br />

Consumer interest in cold-pressed juice<br />

is fueled by research showing that this<br />

type of juicing preserves the integrity<br />

8

made in the usa<br />

<strong>Marketing</strong><br />

ZAHM&NAGEL<br />

producing the highest quality carbonation equipment since 1908<br />

. . . with our 100% satisfaction<br />

guarantee or your money back,<br />

Zahm & Nagel is a trusted name<br />

in the industry built on quality<br />

and service for over 100years.<br />

carbonating stones<br />

series19000 stainless steel<br />

■ 1” diameter in lengths from 4” to 24”<br />

■<br />

■<br />

■<br />

2 micron pore rating<br />

2 PSI break through pressure<br />

Ideal for BBTs from 1 to 60 BBLs<br />

the absolute finest carbonating stone in the industry<br />

series16000 ceramic<br />

■<br />

■<br />

■<br />

■<br />

2” diameter in 4.5” and 10” lengths<br />

.05 micron pore rating<br />

6 PSI break through pressure<br />

Ideal for BBTs 60 BBLs and larger<br />

All Zahm & Nagel carbonation stones include an internal check valve to prevent product backup<br />

into the CO2 lines, with multiple mounting options available. The range of sizes in our series allow<br />

for production versatility and cost. All parts are available for replacement. Durable 304SS<br />

construction polished to a food grade mirror finish, from the producers of the highest quality<br />

carbonation equipment in the brewing industry.<br />

www.zahmnagel.com<br />

e-mail: sales@zahmnagel.com / phone: 716.537.2110<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

9

<strong>Marketing</strong><br />

of vitamins, minerals and enzymes.<br />

This is because the blades encountered<br />

in centrifugal juicing generate heat<br />

and circulate air, both of which have a<br />

deleterious effect on nutrients. With<br />

cold-pressed processing, these elements<br />

are negligible.<br />

Kayco Beyond is debuting Wonder<br />

Lemon, a first-of-its-kind, 100% organic<br />

cold-pressed juice with zero added<br />

sugar. Lemon juice, the primary fruit in<br />

the beverages, is rich in vitamins A and<br />

C, as well as calcium, potassium and<br />

beta-carotene, positioning lemon as<br />

being helpful for immunity, fatigue, and<br />

mood. The drink comes in three flavors:<br />

Lemon Basil Jalapeño, Lemon Ginger<br />

and Lemon Mint, each made with only<br />

five to six ingredients, with less than<br />

110 calories per bottle and made up of<br />

100% natural fruits and vegetables<br />

and no added sugar, artificial flavors,<br />

preservatives, additives or artificial<br />

coloring.<br />

“Lemon has been a popular drink flavor<br />

forever, but most people don’t realize<br />

how much benefit lemons actually<br />

provide,” said Laura Morris, associate<br />

marketing director at Kayco Brands.<br />

“Unlike many other fruits, a lot of<br />

people don’t want to just bite into a<br />

tart, sour lemon, so they just squeeze<br />

it into some water, losing a lot of the<br />

great flavor. That’s why we created<br />

Wonder Lemon, to give our customers<br />

those incredible health benefits while<br />

maintaining the full, delicious flavor of<br />

the lemon.”<br />

Gunna Craft Soft Drinks uses real lemon<br />

juice concentrate, along with other fruits<br />

juices, to make its craft lemonades. Two<br />

of the company’s newest offerings are<br />

Sundowner Lime Lemonade and Turtle<br />

Juice Tropical Lemonade.<br />

When co-founder Chris Prowting<br />

was asked to describe the flavor<br />

development process in three words, he<br />

went with “exciting, fruity and tiring.”<br />

The process involves refining the flavors<br />

from an idea to an excellent drink.<br />

“Having new ideas and inspiration is<br />

relatively easy, but the fun (and hard<br />

work) is in finding the right type and<br />

combinations of flavors to create a<br />

new soft drink that is truly delicious,”<br />

he said.<br />

Each of Gunna’s drinks are named after<br />

the location of the inspiration behind<br />

each recipe. Sundowner, for example,<br />

is inspired by lemon, lime and bitters,<br />

a concoction widely enjoyed across<br />

Australia. Turtle Juice is inspired by a<br />

specific mango daiquiri cocktail enjoyed<br />

in St. Lucia.<br />

“Turtle Juice is packed with sweet<br />

mangos, a zesty twist of lime and a hint<br />

of coconut,” said Prowting. “Adding a<br />

new dimension to traditional mango<br />

drinks, we’ve incorporated the sourness<br />

of lime to cut through the sweet mangos<br />

and a hint of coconut to add a tropical<br />

complexity without overpowering it.”<br />

Garden of Flavor markets a range of<br />

cold-pressed juices. The brand’s newest<br />

offering is Pear Reishi Energy Elixir,<br />

which includes two superfoods: Lion’s<br />

Mane and Chaga mushrooms. Both are<br />

known to support brain health, promote<br />

better sleep and help the body adapt<br />

to stress. These superfoods, along with<br />

reishi, another mushroom, get blended<br />

with ingredients like organic pear juice,<br />

lemon juice, guayusa and probiotic<br />

cultures to help support mental clarity<br />

and energy levels even further.<br />

Adding probiotics to juices is not new,<br />

but really only in the past few years<br />

have consumers caught on that not just<br />

milk and yogurt can be a carrier of these<br />

beneficial live and active bacteria. Juice<br />

can, too.<br />

PepsiCo has been doing it the past few<br />

years under its Naked Juice brand,<br />

which also includes a line of cold-pressed<br />

juices. The brand’s newest offerings are<br />

two vegan smoothies: Orange Vanilla<br />

10

<strong>Marketing</strong><br />

Crème and Key Lime. They combine<br />

almond milk with fruit juices and are<br />

sweetened with monkfruit.<br />

Evive, makers of the blender-less<br />

smoothie, is rolling out three “Super<br />

Functional” offerings. Each superfoodpacked,<br />

certified organic and vegan<br />

smoothie is offered in frozen cubes.<br />

Simply pop into a bottle, add water, juice<br />

or plant-based milk and shake. “Energy”<br />

is a combination of raspberry, blackberry<br />

and mint that helps boost energy without<br />

any caffeine thanks to the addition of<br />

panax ginseng, goji berries, medium<br />

chain triglyceride oil, pitaya powder<br />

and moringa. Banana, mango and beet<br />

round out the energizing effects.<br />

“Zen” has a calming lavender hue<br />

and boasts the subtly sweet flavors of<br />

blueberry, peach, vanilla and lavender.<br />

Light and creamy on the palate,<br />

the drink is packed with superfoods<br />

that support mindfulness, including<br />

ashwagandha, vanilla bean, flaxseed<br />

and wild blueberries. Zen also includes<br />

banana, edamame and avocado, which<br />

amplify the calming effects.<br />

“Immunity” combines cherry, orange,<br />

elderberry and hibiscus into a potent<br />

brew packed with 17 vitamins and<br />

minerals. It also carries superfoods<br />

with key nutrients for immunity,<br />

including camu camu, sea buckthorn<br />

and rosehip; and antioxidant-rich fruits<br />

and vegetables, such as strawberries,<br />

carrots and red bell peppers.<br />

Immunity is a key attraction with many<br />

of today’s juices. Old Orchard Brands<br />

now offers Old Orchard’s Immune Health<br />

Blends, which are 100% fruit juice<br />

fortified with vitamins A, B6, C and E,<br />

along with zinc.<br />

Less sugar also increases a juice’s<br />

market appeal. Uncle Matt’s Organic<br />

is rolling out Matt50 Orange Juice<br />

Beverage. It contains half the sugar and<br />

calories as regular orange juice and is<br />

boosted with vitamin C for immunity,<br />

plus prebiotics and probiotics for gut<br />

health and immune support.<br />

“You can now have your juice and drink<br />

it too with just 50 calories per serving,”<br />

said Susan McLean, vice president of<br />

marketing and innovation. “Sweetened<br />

with organic stevia, Matt50 delivers on<br />

taste and nutrition.”<br />

Another fruit gaining attraction postpandemic<br />

is the Montmorency tart<br />

cherry, which is grown largely in the<br />

U.S. and Canada. These cherries are<br />

abundant in anthocyanins, the natural<br />

flavonoid compounds that contribute<br />

to the ruby-red color and distinctive<br />

sour-sweet taste. The fruit has become<br />

the source of more than 50 studies<br />

supporting varied health and wellness<br />

qualities. It’s most well-recognized<br />

benefit is as an anti-inflammatory agent.<br />

It has been shown to assist with general<br />

pain relief, reducing muscle soreness<br />

after exercise and easing arthritic or<br />

gout pain.<br />

Through the presence of melatonin, a<br />

human sleep regulating hormone, tart<br />

cherries have also gained notoriety<br />

as a natural sleep aid. In addition, as a<br />

concentrated source of vitamin C, tart<br />

cherries serve as a natural immune<br />

system regulator.<br />

FruitHaven’s Super Fruit Juice blends<br />

Montmorency cherries with sweet<br />

cherries, pomegranate, cranberries,<br />

blueberries and currants. With no added<br />

sweeteners, the juice is described as<br />

helping an energy boost for increased<br />

mental and physical strength.<br />

Dole Packaged Foods has entered the<br />

tropical juice category with beverages<br />

with benefits. New Dole Fruitify Glow<br />

combines pineapple and mango juice<br />

with turmeric. Dole Fruitify Energize is<br />

pineapple juice with green tea extract<br />

and Dole Fruitify Replenish is pineapple<br />

juice and coconut water.<br />

Longtime juice category player Ocean<br />

Spray has been busy keeping cranberry<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

11

<strong>Marketing</strong><br />

relevant to consumers. New Frutas<br />

Frescas is a line of light beverages<br />

containing fewer calories and sugar<br />

than leading juice drinks. Available in<br />

three flavor offerings rooted in the<br />

cranberry--Cranberry Pineapple Passion<br />

Fruit, Cranberry Lemon Raspberry<br />

and Cranberry Raspberry Pear--Frutas<br />

Frescas are made with real fruit juice,<br />

no artificial sweeteners and boosted<br />

with vitamin C. In addition, Ocean Spray<br />

has introduced two new flavors of<br />

100% Juice: Cranberry Elderberry and<br />

Cranberry Watermelon.<br />

Graasi Barley Water is a new concept<br />

designed to satisfy consumer cravings<br />

for more hydration, immunity and<br />

overall wellness. The line of ready-todrink<br />

organic waters has organic barley<br />

grass juice powder as a key ingredient.<br />

It comes from the tender young grass<br />

grown from barley seed. Barley grass is<br />

harvested at the peak of its chlorophyll,<br />

protein and vitamin concentration,<br />

before the grass produces any grain.<br />

In addition to the wellness benefits<br />

provided from barley grass juice powder<br />

(fiber, vitamins and antioxidants), each<br />

bottle contains vitamin C, D and zinc.<br />

It comes in three flavors: Citrus Mint,<br />

Cucumber Lime and Lemongrass Ginger.<br />

“When developing a new line of functional<br />

waters, we focused on unique ingredients<br />

that would promote overall wellness<br />

and self-care,” said Chris LaCorata,<br />

founder of Graasi. “Barley water has<br />

been consumed by cultures around the<br />

world for thousands of years as a general<br />

wellness drink. We’re bringing it back and<br />

making it better with organic ingredients<br />

and immunity-boosting vitamins and<br />

minerals.”<br />

Speaking of hydration, pickle juice is now<br />

getting bottled for its benefits. Pickle<br />

juice is loaded with electrolytes in the<br />

form of sodium (from the brine), as well<br />

as some potassium and magnesium,<br />

making it a natural way to rehydrate<br />

after exercise. Pickle juice also contains<br />

probiotics from the natural fermentation<br />

that turns cucumbers into pickles.<br />

Mt. Olive has been offering its pickle juice<br />

in 2-ounce shot-style bottles for a few<br />

years. The company recently rolled out a<br />

64-ounce jug for extra thirsty people.<br />

As consumers learn the benefits of<br />

whole food nutrition, and prioritize<br />

health and wellness, expect to see more<br />

innovations in the fruit and vegetable<br />

juice space.<br />

The Author<br />

Donna Berry is a food and beverage industry<br />

consultant and editor with over 25 years experience<br />

in tracking trends and advancements in<br />

product development.<br />

12

<strong>Marketing</strong><br />

Connect with<br />

nutraceutical<br />

experts<br />

This year, Vitafoods Europe <strong>2022</strong> returns to its annual<br />

May slot in your diary. As it’s a hybrid event you’ll be<br />

able to join us in person and online to share ideas,<br />

see new products, source ingredients and innovate<br />

with an inspiring community of experts. This is your<br />

chance to connect with industry-leading buyers,<br />

suppliers and manufacturers from over 110 countries,<br />

so don’t miss it.<br />

Register for your free<br />

badge now and save €160*<br />

Geneva: 10-12 May<br />

Online: 2-13 May<br />

For more details visit<br />

vitafoods.eu.com<br />

*Onsite visitor registration will cost €160<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

13

Ingredients<br />

Coffee and Cocoa Extracts: Natural<br />

Products Full of Aroma<br />

Coffee and cocoa beans are highly aromatic. This is obvious to anyone who has ever smelled<br />

the intense aroma of freshly milled coffee beans or tasted freshly made cocoa. The raw beans<br />

only develop their full aromatic effect after roasting. That’s why producers from Indonesia use<br />

roasted coffee beans and cocoa powder as the raw materials for creating natural cocoa and<br />

coffee aromas. The extracts contain a large portion of natural aroma. Natural coffee and cocoa<br />

extracts are widely used in the food and drinks industry and can be found in products such as<br />

deserts, baked goods, ice cream, milk products and in the growing segment of iced coffee drinks.<br />

The Import Promotion Desk (IPD) an initiative promoting imports, supports manufacturers of<br />

natural aromatic substances, essential oils and plant extracts in exporting to the European<br />

market and introduces European traders to new partners and products from Indonesia, for<br />

instance at trade fairs – neutrally and free of charge.<br />

High quality natural raw<br />

materials<br />

Indonesia is made up of over 17,000<br />

islands. It has a high level of biodiversity<br />

and is rich in natural resources. One of<br />

the many advantages this brings is the<br />

range of natural ingredients available for<br />

food and drinks. Besides a wide variety<br />

of coconut products, these especially<br />

include spices, such as cinnamon, vanilla<br />

and ginger, from which essential oils and<br />

extracts are produced. And the delicate<br />

coffee and cocoa plants benefit from<br />

the nutrient-rich soil and favourable<br />

climate conditions of the Indonesian<br />

islands, which ensure constantly high<br />

temperatures, high humidity and ample<br />

shadow.<br />

Indonesian coffee is cultivated mainly<br />

in Sumatra, Java, Sulawesi, Flores and<br />

Bali. Formerly, the arabica bean was the<br />

focus of production, which is why it is also<br />

known as java coffee. Today, it is mostly<br />

robusta beans that are cultivated in the<br />

farming regions. And as for cocoa, it is<br />

the criollo variety that grows between<br />

Indonesia’s shadowy coconut palms.<br />

Cooperation with small farmers<br />

Most coffee and cocoa plantations<br />

are worked by small farmers who still<br />

harvest, dry, process and roast the<br />

14

Ingredients<br />

coffee and cocoa beans using traditional<br />

methods. The enterprise Sima Arome, a<br />

specialist producer of natural extracts,<br />

collaborates with a number of small<br />

farmers and processes their harvests to<br />

create high quality natural ingredients.<br />

The direct cooperation with farmers<br />

ensures compliance with standards<br />

like FSCC 22000 and consistent high<br />

quality. The quality of the raw materials<br />

is essential, because it is not only the<br />

variety of the coffee and cocoa beans,<br />

but also the growing conditions, in the<br />

case of cocoa beans the fermentation<br />

process, and the roasting process that<br />

have a major impact on flavor and aroma.<br />

Sima Arome processes the raw materials<br />

in a modern production facility on Java,<br />

established with European technology,<br />

and produces a large range of natural<br />

ingredients, aromatic substances and<br />

essential oils.<br />

Extraction of the coffee and<br />

cocoa aromas<br />

The production of concentrated coffee<br />

and cocoa aromas is done using roasted<br />

beans and the cocoa beans are also<br />

ground to powder. The enterprise Sima<br />

Arome uses the gentle technique of<br />

pressurized liquid extraction (PLE) and<br />

mainly water in the extraction process.<br />

The coffee aroma has the typically bitter<br />

coffee flavor, roasted scent and a slight<br />

caramel note. Taste differences between<br />

the arabica and robusta beans are also<br />

noticeable in the extracts. As well as the<br />

aromatic substances, the other typical<br />

ingredients of the beans are retained.<br />

Thus, cocoa extract contains flavanols,<br />

secondary plant substances of the<br />

cocoa bean, and coffee extract contains<br />

caffeine.<br />

The enterprise Sima Arome also uses<br />

its modern extraction technology to<br />

produce other natural extracts, e.g.<br />

from fruits, ginger, tea and vanilla.<br />

The subsequent spray-drying process<br />

produces double encapsulated powder<br />

extract which has various uses in food<br />

and drink products.<br />

IPD partner country Indonesia<br />

IPD has been supporting small and medium-sized enterprises from Indonesia since 2014, preparing them<br />

for the European market and presenting them to European wholesalers at European trade fairs. The forestry<br />

and farming industry and the associated industries are major contributors to Indonesia’s gross domestic<br />

product and also significant employers. They ensure a source of income and thus the future prospects of the<br />

(young) population of rural regions.<br />

IPD introduces European importers to the carefully selected producers, opening up new purchasing sources<br />

for them and supporting them in the procurement process. IPD is funded by the German Federal Ministry for<br />

Economic Cooperation and Development (BMZ).<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

15

Ingredients<br />

New Survey Shows ‘Positive Ageing’ is<br />

Driving Demand for Healthier Nutrition<br />

New research, conducted on behalf of<br />

BENEO, reveals that consumers are now<br />

even more focused on ‘positive’ ageing.<br />

The research, carried out by HealthFocus<br />

International, includes an exclusive<br />

analysis of the health-conscious 50+<br />

age range. It shows that those aged over<br />

50 want to be able to continue with the<br />

activities that they enjoy in their latter<br />

years and are increasingly looking to<br />

food and drink alternatives to support<br />

this goal.<br />

Getting the best out of the present<br />

and the future is what drives healthconscious<br />

over-50’s. They want to be the<br />

best version of themselves that they can<br />

be in every life-stage. This means taking<br />

control over future health, whilst being<br />

fit and healthy enough to enjoy the<br />

present, and nutrition plays a significant<br />

part in achieving this for them.<br />

For those over-50’s concerned about<br />

the issue of healthy ageing, three out of<br />

every four (79%) are primarily focused<br />

on maintaining their ability to continue<br />

with activities as they age. A similar<br />

number (76%) see good physical and<br />

mental health and a balanced diet as<br />

key to overall health. In particular, the<br />

importance of nutrition is reflected by<br />

the survey results: 42% think a healthy<br />

diet helps to coping better with life's<br />

challenges. Three quarters (74%) are<br />

making a conscious effort to eat a<br />

healthy diet, while more than half (56%)<br />

choose food and drink products that<br />

provide protective or preventive health<br />

benefits. The research findings also show<br />

that offering “better nutrition” is one of<br />

the top influencing factors to consumers<br />

trying a new brand (68%), presenting<br />

food and drink manufacturers with a<br />

great opportunity to drive purchases<br />

by improving the nutrition of their<br />

products.<br />

With regard to health benefits, the<br />

science is widely recognized by this<br />

cohort when it comes to food: 60% agree<br />

that they “accept scientific and technical<br />

improvements to foods and beverages<br />

if they provide the required benefits”.<br />

Interestingly, although only between<br />

10-20% of these health-conscious over-<br />

50’s are personally affected by digestive<br />

health, bone health or blood glucose<br />

issues, half of those surveyed are ‘very<br />

or extremely concerned’ about such<br />

matters. These consumers are actively<br />

looking for food and beverage products<br />

that support their aim of staying healthy<br />

for longer, with more than half choosing<br />

products that promote stronger bones,<br />

improve digestion or manage blood<br />

sugar levels.<br />

Myriam Snaet, Head of Market<br />

Intelligence and Consumer Insights<br />

at BENEO comments: “Today’s over-<br />

50’s want to be their best self. They<br />

want to be proactive in managing<br />

their health and want to live their life<br />

to the fullest, no matter the life-stage<br />

they are in. Being well aware that food<br />

choices have an effect on overall health,<br />

they are looking for food and drink<br />

products that offer additional health<br />

support, such as lowering blood glucose<br />

levels or improving digestive health.<br />

Manufacturers can help them achieve<br />

these goals by developing products that<br />

tap into these specific health benefits<br />

through the use of BENEO’s functional<br />

ingredients, including the slow-release<br />

sugar, Palatinose and prebiotic chicory<br />

16

Registration opens March<br />

Ingredients<br />

1<br />

July 10–13, <strong>2022</strong><br />

McCormick Place | Chicago, IL<br />

Reconnect Learn Innovate<br />

Stay connected with the latest<br />

IFT FIRST updates at iftevent.org.<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

17

Ingredients<br />

root fibers oligofructose and inulin, that<br />

can easily fit into their daily routines<br />

without compromising on taste.”<br />

Steve Walton, President at HealthFocus<br />

International also comments: “People<br />

are taking charge of their health and<br />

making serious changes. While some<br />

of these new eating patterns and<br />

nutritional adjustments happened due<br />

to COVID-19, we expect many of them to<br />

be long-lasting. We’ve seen a real shift<br />

over the past 10 years and now, healthy<br />

ageing and the quality of life it can give<br />

are top of mind today. Consumers are<br />

adopting a long-term approach to health<br />

maintenance, which highlights that<br />

healthy ageing is relevant for every age.<br />

A fact that food and drink manufacturers<br />

can use to their advantage when looking<br />

at new product development.”<br />

For producers looking to make the most<br />

of the increasing consumer desire to<br />

manage their blood glucose, bone health<br />

and digestive health, BENEO’s products<br />

offer solutions that are backed by sound<br />

science. A person’s blood glucose levels<br />

are a key way to help promote long-term<br />

health, and this is why choosing the right<br />

carbohydrate is so important. BENEO’s<br />

Palatinose (isomaltulose) is a slowrelease<br />

sugar which occurs naturally in<br />

honey and is derived from sugar that is<br />

naturally extracted from sugar beets. It<br />

is unique in its ability to deliver a lower<br />

rise in blood glucose, whilst providing<br />

full carbohydrate energy. It supplies the<br />

body with 4 kcal/g and contributes to<br />

daily energy intake from carbohydrates,<br />

thus making it an ideal ingredient to<br />

help support blood sugar management.<br />

When it comes to digestive health, gut<br />

friendly foods - such as prebiotics - can<br />

help with nourishing the microbiota as<br />

a person gets older. BENEO’s prebiotic<br />

chicory root fibres oligofructose and<br />

inulin play an important role in selectively<br />

promoting the growth of good bacteria<br />

and this in turn supports a person’s<br />

inner defence system. In fact, inulin<br />

and oligofructose are the only proven<br />

plant-based prebiotics. Orafti® Inulin<br />

and Oligofructose have been shown to<br />

support a healthy microbiota and the<br />

selective increase in bifidobacteria in<br />

over 50 human intervention studies<br />

and an increase in stool frequency in 20<br />

human intervention studies.<br />

For further details and insights on the<br />

research, Myriam Snaet, Head of Market<br />

Intelligence and Consumer Insights at<br />

BENEO, is available for comment.<br />

18

Best of Both Worlds: Vitafoods Europe<br />

Returns as a SMART event for <strong>2022</strong><br />

Ingredients<br />

Registrations are now open for Vitafoods Europe <strong>2022</strong> both online and in-person this May<br />

Vitafoods Europe is set to return<br />

as a market-leading SMART event<br />

this summer, combining popular inperson<br />

attractions with a lively online<br />

programme designed to inspire<br />

nutraceutical professionals around the<br />

world. Attendees will be able to access<br />

the online platform a week before the<br />

live event (2-13 May) to watch exclusive<br />

insight-lead content and use the datadriven<br />

matchmaking tool to conduct<br />

virtual meetings. Plus, the platform<br />

and SMART technology enables them<br />

to plan their visit to Geneva and set<br />

up in-person meetings in advance to<br />

ultimately enhance their experience<br />

and maximize their time at the event<br />

between 10-12 May.<br />

“With over 22,000 virtual and in-person<br />

attendees, Vitafoods 2021 was a huge<br />

success, despite the challenges of the<br />

ever-changing COVID-19 situation in<br />

the build up to the event’s return. Now,<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

19

Ingredients<br />

Vitafoods Europe is back for <strong>2022</strong> –<br />

at its usual May timing – providing<br />

opportunities for collaboration in ways<br />

that could only have been dreamed<br />

of when the exhibition started back in<br />

1997,” says Chris Lee, Managing Director<br />

at Informa Markets. “Not only do we<br />

have a truly exciting agenda, but our<br />

enhanced SMART event is designed to<br />

increase connectivity and enhance the<br />

in-person experience. By allowing the<br />

industry to connect ahead of the event,<br />

for example to set up virtual meetings<br />

as well as plan face-to-face meetings<br />

in Geneva, we’re enabling everyone to<br />

expand their global network and make<br />

the most of their time at Vitafoods<br />

Europe.”<br />

With an agenda exploring market trends,<br />

regulatory complexities, packaging<br />

and labelling challenges and more –<br />

including women in nutraceuticals and<br />

sustainability – the SMART event will<br />

provide opportunities to network and<br />

explore the latest industry trends and<br />

innovations both online or in-person.<br />

Highlights of this year’s event include:<br />

• Extensive expert presentations<br />

across 4 theatres – featuring the<br />

Main Stage, powered by Vitafoods<br />

Insights, Life Stages, New Ingredients,<br />

and Probiotics theatres, with over 90<br />

hours of content available across the<br />

whole event.<br />

• Tailored networking opportunities –<br />

enabled by an intelligent data-driven<br />

matchmaking service, the SMART<br />

event allows visitors to find and<br />

connect with potential partners both<br />

in-person and online.<br />

• Innovation tours – available in video<br />

and audio format to enable visitors to<br />

discover the cutting-edge ingredients,<br />

formulations, products and services<br />

on offer at the show.<br />

• Themed Resource Centers – including<br />

the New Ingredients & Products Zones<br />

and, as well as the Omega-3 and<br />

Probiotics Resource Centers.<br />

20

www.anugafoodtec.com<br />

Ingredients<br />

International<br />

supplier fair for the<br />

food and beverage industry<br />

ONE FOR ALL.<br />

ALL IN ONE.<br />

Food Processing | Food Packaging | Safety & Analytics | Intralogistics<br />

Digitalisation | Automation | Environment & Energy | Science & Pioneering<br />

COLOGNE, GERMANY<br />

26.–29.04.<strong>2022</strong><br />

Special Edition!<br />

Be part of it -<br />

find out more here!<br />

Koelnmesse GmbH<br />

Messeplatz 1<br />

50679 Köln, Germany<br />

Tel. +49 1806 578 866<br />

Fax +49 221 821 99-1020<br />

anugafoodtec@visitor.koelnmesse.de<br />

21

Events<br />

Let Your Inspiration Flow<br />

22

Events<br />

World’s Leading Trade Fair for the<br />

Beverage and Liquid Food Industry<br />

September 12–16, <strong>2022</strong><br />

drinktec.com<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

23

Processing<br />

It’s all about the Mix – for Beer Exports<br />

and Industrial Hoses<br />

Hops, barley malt and clear water are<br />

the essential ingredients for one of<br />

the world’s most popular beverages:<br />

Beer. Every year, the world’s largest<br />

hop wholesaler, the BarthHaas Group<br />

in Nuremberg, Germany, provides the<br />

most important statistics, facts and<br />

figures about the brewing industry in its<br />

annual report. According to BarthHaas,<br />

around 1.8 billion hectoliters of beer<br />

were brewed in 172 countries in 2020.<br />

This corresponds to 36 million 50-liter<br />

barrels, or 246 times the amount of<br />

beer consumed at Munich’s famous<br />

Oktoberfest. In 2019, no fewer than 7.3<br />

million one liter beer mugs were filled at<br />

the last beer festival before the corona<br />

virus pandemic.<br />

However, it is not Germany that leads<br />

the way in beer production: In 2020, the<br />

world’s largest producers were China,<br />

the USA, Brazil, and Mexico. Germany<br />

takes fifth place, ahead of Russia, Japan,<br />

Vietnam, Poland and Spain. While the<br />

trend toward more and more types and<br />

specialty beers is apparent in Germany,<br />

traditional beers brewed according to<br />

the German Reinheitsgebot (purity law)<br />

are in demand on the global market.<br />

Despite this diversity, many beers from<br />

all over the world have one thing in<br />

common: They flow through food safe<br />

special purpose hoses from Continental<br />

before they reach the tap.<br />

Bavarian brewing traditions and<br />

modern strategies also coincide<br />

at OeTTINGER<br />

The OeTTINGER brewery also relies<br />

on hose solutions from Continental<br />

and has enjoyed longstanding success<br />

on international markets as a “global<br />

brand made in Germany”. The<br />

Oettingen, Gotha, Mönchengladbach<br />

and Braunschweig brewing plants<br />

produce around 40 specialty beers and<br />

mixed beers as well as soft drinks – for<br />

the domestic market and worldwide<br />

export. The origins of the OeTTINGER<br />

brewery date back to 1731. Over the<br />

past 60 years, the Kollmar owner family<br />

has developed the company from a<br />

small village brewery in the Donau-Ries<br />

region to one of Germany’s largest beer<br />

brands measured in terms of output and<br />

number 25 among the world’s largest<br />

breweries. “My family firmly has faith<br />

in one of the most beautiful products in<br />

the world: Beer. Beer is part of our family<br />

history and is, so to speak, in our DNA,”<br />

says Pia Kollmar, managing partner at<br />

the brewery.<br />

24

We bring colour into view!<br />

Compact capacitive level switches with<br />

360° custom-colour status display<br />

Processing<br />

256 colours<br />

Individually selectable:<br />

Measurement in progress<br />

Sensor switching<br />

Process malfunction<br />

Compact design<br />

NEW!<br />

15 cm<br />

Absolutely<br />

front-flush<br />

design<br />

Hygienic<br />

adapter system<br />

Adjustment via<br />

smartphone<br />

www.vega.com/vegapoint<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

25

Processing<br />

At the start of the new millennium,<br />

the Bavarian family-owned company<br />

dipped its toe in international business,<br />

scoring an impressive success. Today,<br />

its beer is consumed in more than 100<br />

countries around the world, with around<br />

one third of annual production going<br />

for export. This puts OeTTINGER in 2nd<br />

place in the export ranking of German<br />

brewers. The most important foreign<br />

markets for the family-owned company<br />

are Italy, China, Belgium, Switzerland,<br />

Russia and the Netherlands. Countryspecific<br />

preferences are obvious: While<br />

the “Original OeTTINGER Super Forte”<br />

strong beer is mainly delivered to<br />

China, Italy, and Peru, “Naturally Cloudy<br />

Original OeTTINGER Radler” is popular<br />

in Taiwan, Uruguay, and Ecuador.<br />

Overall, however, the traditional wheat<br />

beer, export and pils types dominate the<br />

brewery’s export portfolio; mixed drinks<br />

are considered niche products. After<br />

all, German beer enjoys a worldwide<br />

reputation for its pure taste, purity and<br />

natural ingredients. In fact, the German<br />

purity law is the oldest food law still in<br />

force today. As early as 1516, the Dukes<br />

of Bavaria decreed that beer should be<br />

brewed exclusively from barley, hops and<br />

water.<br />

Hoses from Continental<br />

withstand the challenges of<br />

everyday brewing<br />

Not only do the high-quality ingredients<br />

required under the purity law contribute<br />

to the taste experience, but food<br />

safe materials and hygiene are just<br />

as important in the brewing process.<br />

At OeTTINGER’s highly automated<br />

manufacturing facilities, special-purpose<br />

hoses such as the “Purple Snake”<br />

and the “Aquapal” from Continental<br />

play an important role in food safety.<br />

The technology company supplies not<br />

only hoses, but also complete lines<br />

with crimped fittings. These complete<br />

solutions are particularly hygienic<br />

because both components fit seamlessly<br />

into one another; there is almost no<br />

place for germs to hide and turbulence<br />

is almost completely ruled out. The<br />

fixed, hygienically flawless connection<br />

between the rubber tubing and the<br />

fitting can withstand pressures of up to<br />

16 bar with triple safety.<br />

Of particular importance for use in the<br />

food industry is the fact that the smooth<br />

inner liner of Continental hoses, referred<br />

to as the soul of the hose, is absolutely<br />

odorless and taste-neutral. It conforms to<br />

the XXI recommendations of the German<br />

Federal Institute for Risk Assessment<br />

(BfR) as well as the directives of the<br />

Food and Drug Administration (FDA)<br />

in the US. The special elastomer inner<br />

layer in the “Purple Snake” is completely<br />

non-porous. Synthetic yarns with two<br />

spiralized copper strands have proven<br />

their worth as pressure carriers. The<br />

outer layer, in turn, is made of a special<br />

abrasion-resistant elastomer and, with its<br />

ribbed surface, is ozone-, weather-, and<br />

UV-resistant. In the “Aquapal”, the soul<br />

of the hose is made from plasticizer-free<br />

fluoro plastic. As with the “Purple Snake”,<br />

synthetic yarn is used as a pressure<br />

carrier. The characteristic blue hose<br />

26

Processing<br />

cover of the “Aquapal” is resistant to oils<br />

and greases, as well as abrasion and also<br />

ozone, weathering and UV impact.<br />

“Our material blends have been adapted<br />

to market requirements, ensuring<br />

maximum safety over a long period<br />

of use,” explains Georg Bester, who<br />

is responsible for food hose sales at<br />

Continental and an expert in technical<br />

consulting. Bester’s many years of<br />

experience mean he knows exactly<br />

the stringent requirements for hose<br />

solutions: “Hoses in breweries are used<br />

and cleaned extremely frequently –<br />

so they have to withstand high levels<br />

of stress. Our hoses can withstand<br />

temperatures of up to +95°C and are<br />

chemical-resistant and robust i.e.,<br />

designed for challenging applications.<br />

At the same time, the hoses can be used<br />

very flexibly. They are suitable for a wide<br />

range of media – various types of beer,<br />

mixed beer and soft drinks, alkalis and<br />

cleaning agents,” explains Bester.<br />

Sven Willim, deputy production<br />

manager at the OeTTINGER Brewery<br />

in Möchengladbach, confirms the<br />

remarkable properties of Continental’s<br />

food hoses produced in Korbach in the<br />

German state Hesse. “Our employees<br />

can give the hoses a lot of punishment,<br />

laying lines spontaneously and<br />

sometimes dragging them over the<br />

floor without causing them to twist or<br />

get damaged,” explains Willim. In some<br />

cases, Continental hoses are used for<br />

up to ten years – without compromising<br />

on quality: “This is confirmed time and<br />

again by regular microbiological samples<br />

of liquids and hose tests by independent<br />

organizations.”<br />

<strong>drinkworld</strong> <strong>Technology</strong> + <strong>Marketing</strong> · March <strong>2022</strong><br />

27

Processing<br />

Key Role for Quality<br />

KHS supports beverage producer UCB from Cameroon in implementing its ambitious<br />

sustainability goals<br />

On the booming beer market in<br />

Cameroon one local brewery isn’t simply<br />

out to make a few fast bucks – or francs<br />

– but is instead going for sustainability,<br />

high-quality products and future-proof<br />

technology. This strategy is proving<br />

extremely successful and has made the<br />

company the market leader in major<br />

cities.<br />

Fast urbanization and a rapidly growing<br />

middle class are turning large swathes<br />

of the African continent into a dynamic<br />

market that holds great potential. With<br />

their sales markets in North America<br />

and Europe stagnating or declining, this<br />

is something international breweries<br />

especially are profiting from and<br />

where they see new opportunities.<br />

Consumption is rising every year by 5%;<br />

in 2015 experts from the Deutsche Bank<br />

already forecast that by 2025 more<br />

than a third of the growth in worldwide<br />

beer sales would be attributable to sub-<br />

Saharan Africa.<br />

This trend is also evident in Cameroon,<br />

whose gross domestic product has<br />

more than doubled over the last 15<br />

years. However, it’s not just the big<br />

international names that are quenching<br />

the increasing thirst of the population<br />

here. One local business is also in the<br />

same top league as the major players:<br />

Union Camerounaise de Brasseries<br />

(UCB) based in the port of Douala ranks<br />

second on the Central African market<br />

between two big global breweries. With<br />

its traditional King Beer and Kadji Beer<br />

and K44 brands UCB is very popular<br />

in Cameroon. The company is also<br />

heralded as something of a pioneer. A<br />

considerable amount has been invested<br />

in new technology since 2016: this<br />

includes two new returnable glass lines,<br />

for example, for which KHS supplied the<br />

entire packaging and palletizing sections<br />

in 2019 and 2020. Furthermore, in May<br />

of 2021 a KHS PET line – UCB’s very first–<br />

was commissioned for the relatively new<br />

segment of soda pop and water. It has a<br />

capacity of up to 20,000 bottles per hour<br />

and comprises a stretch blow molder/<br />

filler block, labeler, packaging machine<br />

and palletizing equipment. At the time<br />

of writing UCB is also considering filling<br />

its beverages into cans; in keeping with<br />

its role as a trailblazer, this would make<br />

it the first brewery in Cameroon to<br />

operate its own can filling process.<br />

The line at UCB includes an Innopack Kisters SP, a shrink packer that wraps and bundles the packs in shrink film.<br />

28

We understand how you strive for constant<br />

product quality and optimized costs.<br />

Processing<br />

CONSISTENT<br />

+ CONFIDENT<br />

You are poised to meet your safety and quality<br />

requirements while optimizing resources and<br />

securing process repeatability.<br />

Endress+Hauser helps you to improve your processes:<br />

• With a hygienic, robust product portfolio that meets<br />

international standards<br />

• With access to traceable, reliable and real-time data<br />

• With a network of industry application experts that help<br />

you ensure greater plant availability throughout the<br />

product life cycle<br />

Do you want to learn more?<br />

<strong>drinkworld</strong> <strong>Technology</strong> www.endress.com/food-beverage<br />

+ <strong>Marketing</strong> · March <strong>2022</strong><br />

29

Processing<br />

On schedule<br />

The coronavirus pandemic caused a<br />

number of delays among sub-suppliers<br />

responsible for preceding work,<br />

particularly in 2020, that could be largely<br />

compensated for as both the packaging<br />

and palletizing sections of the second<br />

glass line and the new PET line were<br />

more or less fully implemented by the<br />

KHS subsidiary in Nigeria. This meant<br />

that installation and commissioning were<br />

completed within the given time frame.<br />

Many other KHS projects currently in<br />

progress in Cameroon illustrate that<br />

the country is booming and steadily<br />

becoming an attractive market for the<br />

Dortmund systems supplier. In the past,<br />

the French-speaking countries of Africa<br />

especially imported a large percentage<br />

of their beverages. However, more and<br />

more local retailers and bottlers are now<br />

asking themselves why they should ship<br />

beverages in from Europe when they<br />

could bottle them themselves in their own<br />

region.<br />

In the following interview, Whalen Kadji,<br />

project manager for the Kadji Group and<br />

one of the brewery founder’s grandsons,<br />

gives us an insight into his company’s<br />

philosophy and sustainability strategy and<br />

talks about its cooperation with KHS.<br />

How would you describe UCB’s<br />

corporate philosophy?<br />

Our company is characterized both<br />

by the deep roots it has in the culture<br />

of Cameroon and by our wish to<br />

Whalen Kadji is convinced that UCB has made exactly the right choice in opting for KHS.<br />

View of the line’s packaging section: in the center is the labeler, with the packer to the right and the<br />

conveyors with buffer segments in front of and between the two.<br />

become better and better. Founded in<br />

1972, we’ve always put quality before<br />

quantity and have thus been able to<br />

retain our expertise and individuality.<br />

As proud Cameroonians we still stand<br />

for perfect craftsmanship in brewing<br />

and believe in only using the best<br />

ingredients.<br />

Quality seems to be an<br />

important factor for your<br />

brewery. How do you establish<br />

and maintain your high<br />

standards of quality?<br />

Our core values are creativity, integrity<br />

and courage. Quality also indeed plays<br />

a key role for us – in our processes and<br />

in our dealings with our partners, both<br />

in Cameroon and abroad. With the<br />

help of a dedicated system of quality<br />

management, with precise planning<br />

and strict methods of measurement we<br />

achieve top performance at practically<br />

every point in the value chain.<br />

What have been the most<br />

significant success factors in<br />

the almost 50 years of your<br />

company?<br />

For us, people have always been<br />

the key to our success. Our founder<br />

Joseph Kadji Defosso envisaged a<br />

Long-term partners UCB and KHS: Benedict<br />

Jatto, sales and marketing manager for KHS<br />

Machines Nigeria, Alexander Fuchs, managing<br />

director of KHS Machines Nigeria and Whalen<br />

Kadji, project manager for the Kadji Group,<br />

which UCB is part of (from left to right).<br />

30

Processing<br />

company that would become one of<br />

the best in its field. Besides this vision<br />

he also had the will and determination<br />

to achieve this goal. Now, under the<br />

leadership of Nicole Kadji Defosso,<br />

his daughter, we’re constantly on<br />

the lookout for first-class employees<br />

whose professional attitude and<br />

qualifications satisfy the highest<br />

standards and who are able to tread in<br />

Joseph Kadji’s great footsteps.<br />

If we now turn to the bottling of<br />

your products, which container<br />

segments are most important<br />

in Cameroon? And what role<br />

does sustainability play in this<br />

context?<br />

On our home beer market the<br />

returnable glass bottle definitely<br />

has the lion’s share. Beer can be<br />

pasteurized in this type of container,<br />

meaning that it keeps longer. What’s<br />

more, the glass acts as a CO 2<br />

diffusion<br />

barrier, thus ensuring long-lasting<br />

quality on the shelf. Moreover, bar<br />

proprietors and owners of small stores<br />

find it of great benefit that the empties<br />

are collected from their properties.<br />

Finally, for our part we procure our<br />

bottles from a local glass factory that<br />

can also recycle glass. This therefore<br />

means that this is a tried-and-tested<br />

and sustainable material for container<br />

manufacture on all counts.<br />

Which trends and developments<br />

The KHS Innoket Neo roll-fed labeler dresses the PET bottles on the line with labels.<br />

A KHS service employee shows UCB operators how to change reels on the Innoket Neo for roll-fed<br />

labeling.<br />

do you see emerging in relation<br />

to beverage packaging in<br />

Cameroon?<br />

PET has enjoyed a rise in popularity<br />

in conjunction with carbonated soft<br />

drinks and water for some time now.<br />

Unfortunately, we don’t yet have a bottleto-bottle<br />

recycling system in Cameroon,<br />

however. At the moment plastic bottles<br />

are merely pressed, shredded and sent<br />

to a PET materials manufacturer. In view<br />

of their rapidly increasing use and the<br />

subsequent growing amount of plastic<br />

waste, the PET recycling process still<br />

needs to become established here. Cans<br />

and kegs made of aluminum could be<br />

an alternative to this material but at<br />

present this is still a very small segment,<br />

albeit one that’s growing. This is based<br />

on the premize that these containers are<br />

made locally, however. Cameroon needs<br />

to catch up here.<br />

Is plastic waste a big issue in<br />

your country? What are the<br />

state and the economy doing to<br />

prevent it?<br />

Plastic and especially PET waste is<br />

indeed a big problem. We do have a few<br />

state regulations and levies in place<br />

but they have very little impact. One<br />

major reason for this is, for example,<br />

that empty PET bottles are often<br />

reused for a totally different purpose,<br />

although there are repeated warnings<br />

not to do so. For the Kadji Group, which<br />

UCB is part of, the protection of the<br />

environment has a high priority. We’ve<br />

thus entered into partnership with a<br />

number of startups that invest in PET<br />

recycling. Among them is a company<br />

that makes school bags and pencil<br />

cases from recycled PET and another<br />

that presses and bundles returned<br />

bottles and sends them to recyclers in<br />