UC4™ Total Control™ Quick Guide - NORAC Systems

UC4™ Total Control™ Quick Guide - NORAC Systems

UC4™ Total Control™ Quick Guide - NORAC Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

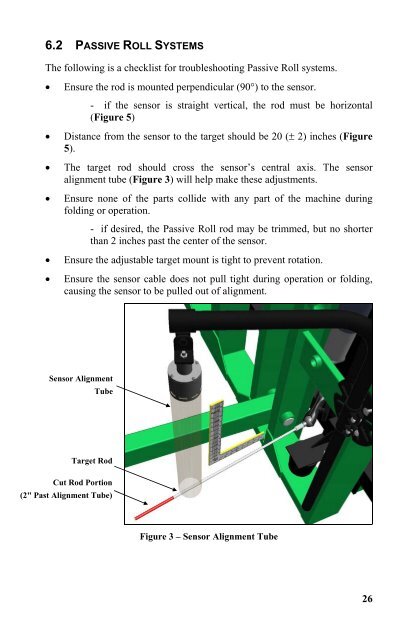

6.2 PASSIVE ROLL SYSTEMS<br />

The following is a checklist for troubleshooting Passive Roll systems.<br />

• Ensure the rod is mounted perpendicular (90°) to the sensor.<br />

- if the sensor is straight vertical, the rod must be horizontal<br />

(Figure 5)<br />

• Distance from the sensor to the target should be 20 (± 2) inches (Figure<br />

5).<br />

• The target rod should cross the sensor’s central axis. The sensor<br />

alignment tube (Figure 3) will help make these adjustments.<br />

• Ensure none of the parts collide with any part of the machine during<br />

folding or operation.<br />

- if desired, the Passive Roll rod may be trimmed, but no shorter<br />

than 2 inches past the center of the sensor.<br />

• Ensure the adjustable target mount is tight to prevent rotation.<br />

• Ensure the sensor cable does not pull tight during operation or folding,<br />

causing the sensor to be pulled out of alignment.<br />

Sensor Alignment<br />

Tube<br />

Target Rod<br />

Cut Rod Portion<br />

(2" Past Alignment Tube)<br />

Figure 3 – Sensor Alignment Tube<br />

26