Food & ingredients December 2022

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

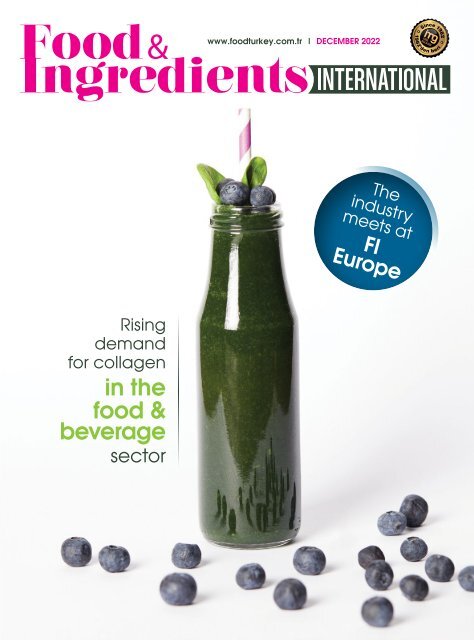

www.foodturkey.com.tr | DECEMBER <strong>2022</strong><br />

The<br />

industry<br />

meets at<br />

FI<br />

Europe<br />

Rising<br />

demand<br />

for collagen<br />

in the<br />

food &<br />

beverage<br />

sector

Berlin<br />

8|9|10 Feb 2023<br />

All in<br />

ONE<br />

Take part at the leading trade show<br />

for the global fresh produce business.<br />

fruitlogistica.com

THIS<br />

MONTH<br />

HIGHLIGHTS<br />

4<br />

Top 10 trends for the<br />

food and beverage<br />

industry in 2023<br />

12<br />

IFF excels in innovation<br />

for a better world<br />

16<br />

Eco-friendly, energy<br />

saving, hygienic:<br />

efficient sanitisation with<br />

microwave and radio<br />

frequency systems by<br />

SAIREM<br />

20<br />

Dehydrated potato market<br />

sheds light on changing<br />

consumer habits<br />

26<br />

Immune health still top<br />

priority for functional<br />

beverage consumers, but<br />

other needs on the rise<br />

30<br />

Dubai World Trade Centre<br />

and DMG events partner<br />

to develop new portfolio<br />

of global events for the<br />

food sector<br />

38<br />

Lakidis offers highest<br />

quality food machinery<br />

The next issue<br />

will be at

Ayça SARIOGLU<br />

Coordinator<br />

ayca.sarioglu@img.com.tr<br />

It’s really inspiring<br />

and exciting!<br />

At a time when global food crisis and<br />

halts in supply chain are pronounced,<br />

the flow of industry professionals to Dubai<br />

makes it a fascinating event. We all know<br />

what a fabulous fair Gulfood and Gulfood<br />

Manufacturing are from the more miserable<br />

times. They were very much successful even<br />

amid the pandemic. Now, it is expected<br />

that both fairs and their concurrent event<br />

will be a hub of the industry to generate<br />

unbelievably high trade.<br />

Powering groundbreaking innovation<br />

in the F&B Industry, Gulfood Manufacturing<br />

<strong>2022</strong> was the definitive destination to see<br />

the future of food production – from<br />

new <strong>ingredients</strong> and advanced<br />

technologies to integrated supply chain<br />

solutions and breakthrough developments<br />

driving the industry forward. Gulfood<br />

Manufacturing is certainly a venue to<br />

straight up the FB industry.<br />

The timing of Gulfood Manufacturing<br />

and Gulfood have been set excellent.<br />

November is a good time for<br />

manufacturing techniques and materials<br />

and February is the best time to push the<br />

button for food and beverage production.<br />

Any professional operating in the industry<br />

certainly find what they need for buying,<br />

selling, developing, getting inspired and<br />

learning whatever they need to know.<br />

We, <strong>Food</strong> & Ingredients International<br />

magazine, a close follower of<br />

international events, have just come from<br />

Gulfood Manufacturing, where we saw<br />

a huge interest in terms of quality and<br />

quantity of exhibitors as well as visitors.<br />

Gulfood Manufacturing was marvelous<br />

as expected. The variety of products,<br />

trendsetting displays, supporting events<br />

and flow of every organized work were<br />

all very professional. Now we will be at FI<br />

Europe Paris. FI Europe is also expected<br />

to be a fascinating venue for all players<br />

of the food <strong>ingredients</strong> industry. FI Europe<br />

visitors will have <strong>Food</strong> & Ingredients<br />

magazine during the show.<br />

We already set up for 2023, you will see<br />

us in Gulfood Dubai, Fruit Logistica,<br />

Interpack, Anuga, ISM, FI India, FI Europe<br />

and many more…<br />

I wish a healthy, happy and prosperous year<br />

and lucrative business for all industry reps.<br />

Publisher<br />

Hüseyin Ferruh IŞIK<br />

on behalf of<br />

ISTMAG<br />

Magazin Gazetecilik Yayıncılık<br />

İç ve Dış Tic. Ltd. Şti.<br />

Managing Editor (Responsible)<br />

Mehmet SOZTUTAN<br />

mehmet.soztutan@img.com.tr<br />

Editor<br />

Ali ERDEM<br />

info@img.com.tr<br />

International<br />

Sales Coordinator<br />

Ayca SARIOGLU<br />

ayca.sarioglu@img.com.tr<br />

+90 212 454 22 33<br />

Technical Manager<br />

Tayfun AYDIN<br />

tayfun.aydin@img.com.tr<br />

Graphics & Design<br />

Hakan SOZTUTAN<br />

hakan.soztutan@img.com.tr<br />

Digital Assets Manager<br />

Emre YENER<br />

emre.yener@img.com.tr<br />

Subscription<br />

sales@img.com.tr<br />

HEAD OFFICE<br />

İSTMAG MAGAZİN GAZETECİLİK YAYINCILIK<br />

İÇ VE DIŞ TİC. LTD. ŞTİ.<br />

İHLAS MEDIA CENTER<br />

Merkez Mahallesi 29 Ekim Caddesi No: 11<br />

Medya Blok Kat: 1 P.K. 34197<br />

Yenibosna - Bahçelievler / İSTANBUL / TURKEY<br />

Tel: +90 212 454 22 22 Fax: +90 212 454 22 93<br />

LIAISON OFFICE<br />

Buttim Plaza A Blok Kat: 4 No: 1038<br />

Bursa / TURKEY<br />

Tel: +90 224 211 44 50-51 Fax: +90 224 211 44 81<br />

PRINTED BY | İH LAS GAZETECİLİK A.Ş.<br />

İHLAS MEDIA CENTER Merkez Mahallesi<br />

29 Ekim Caddesi No: 11 A/41<br />

Yenibosna - Bahçelievler / İSTANBUL / TURKEY<br />

Tel: +90 212 454 30 00<br />

www.foodturkey.com.tr<br />

sales@img.com.tr<br />

foodturkeymagazine<br />

foodturkeymag<br />

food<strong>ingredients</strong>turkeymag<br />

<strong>Food</strong> Ingredients Turkey<br />

<strong>Food</strong> & Ingredients Turkey

Create Delicious Better-For-You<br />

Products with Sweegen<br />

Consumers want delicious food and beverages with less sugar. Create<br />

better-for-you products that meet consumer taste expectations with<br />

Sweegen’s exclusive Nature-Based Sweetener Systems.<br />

You Have a Choice. Choose Well.<br />

Sweegen is a finalist in the<br />

Fi Europe Innovation Awards <strong>2022</strong><br />

<strong>Food</strong> Technology Innovation<br />

Award category for our<br />

Novel Bioconversion Process<br />

for Production of Bestevia® Reb M.<br />

Follow us on:<br />

www.sweegen.com

“Redefining Value”<br />

heads Innova Market<br />

Insights’ Top Ten Trends<br />

for 2023, as consumers<br />

adapt to a global costof-living<br />

crisis in the<br />

face of economic and<br />

political volatility. With<br />

budgets stretched and<br />

supplies under strain,<br />

brands need to be<br />

flexible in action and<br />

open in spirit to connect<br />

with consumers,<br />

while also taking full<br />

advantage of rapidly<br />

emerging technological<br />

opportunities.<br />

Top 10 trends for the food and<br />

beverage industry in 2023<br />

The eagerly awaited annual trends from food<br />

innovation and insight specialist Innova are<br />

based on wide-ranging global consumer<br />

surveys. Coupled with comprehensive market<br />

and new product data, they reveal not only<br />

what is driving consumer decisions now, but<br />

also ways in which brands and innovators can<br />

successfully adapt to future realities.<br />

Over the last year, cost and value for money<br />

have become more important to more than half<br />

of food and beverage consumers worldwide.<br />

Today’s shoppers are increasingly exploring<br />

money-saving strategies, such as choosing lower<br />

cost items and cooking from scratch. But they<br />

remain determined to sample new experiences,<br />

ensure personal wellbeing and support<br />

planetary health. There is more pressure on<br />

brands and manufacturers to deliver value while<br />

still meeting these wider public expectations.<br />

“Redefining value throughout the food<br />

and beverage industry will lead in 2023 as<br />

consumers seek brands that listen, understand<br />

and respond to their core values. They<br />

want brands that provide quality, trust and<br />

4 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

confidence via their product formulations,<br />

communications and wider sustainability<br />

actions,” highlights Lu Ann Williams, Global<br />

Insights Director at Innova Market Insights.<br />

In addition to a heightened demand for<br />

competitive pricing, consumers have told Innova<br />

they still seek nutritional value and expect a<br />

continued shared responsibility for environmental<br />

security. Meanwhile, younger generations who<br />

have grown up in an inclusive digital age are<br />

gaining greater influence, changing markets<br />

and creating new opportunities. Against that<br />

complex backdrop, here’s a taste of what<br />

Innova’s Top Ten Trends show is in store for the<br />

food and beverage industry in 2023:<br />

1. Redefining value<br />

Brands, innovators, producers and consumers<br />

are wrestling with rising costs and greater<br />

instability. Combating this requires a deep<br />

understanding of where consumers draw the<br />

line on compromise. Strategies such as simple<br />

price increases, or flexible ingredient lists to<br />

cope with supply chain fluctuations, can work<br />

in the short term. However, brands need to be<br />

open in their communication and clearly show<br />

the benefits they are bringing.<br />

Despite political and economic volatility<br />

becoming the second biggest concern for<br />

consumers in <strong>2022</strong>, the health of the planet<br />

remains the top global issue and financial<br />

pressures are leading to an increase in ecofriendly<br />

behaviors. Consumers tell Innova they<br />

have reduced food waste and upcycled or<br />

recycled more as part of their belt-tightening.<br />

As the cost-of-living crisis continues, brands<br />

can achieve success through actions that<br />

combine economic benefits with clear<br />

health and sustainability goals.<br />

2. Affordable nutrition<br />

Over the past 12 months, 62% of consumers<br />

have reported a noticeable rise in the cost<br />

of their food and beverages. As a result,<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

5

see improvements in taste and texture, but<br />

there is a huge appetite for culinary creativity<br />

and worldwide flavor profiles. Two-thirds<br />

of respondents to Innova’s global survey<br />

expressed a desire to try plant-based versions<br />

of traditional, local cuisines. The industry is<br />

responding with a large increase in readymeal<br />

offerings, while there is great scope for<br />

expansion into meal kits and inventive recipe<br />

combinations. Interest in underused <strong>ingredients</strong><br />

is also growing, creating opportunities to<br />

introduce variation in flavor and nutrition while<br />

simultaneously addressing supply concerns.<br />

they are turning their attention to simple but<br />

nutritious goods that are affordable. Key<br />

behaviors include buying in bulk, opting for<br />

private labels, cooking from scratch, reducing<br />

spending on luxury items and purchasing<br />

fewer items. Consumers are actively looking<br />

for affordable ways to maintain a healthy<br />

diet, offering brands many opportunities to<br />

test their capabilities to new limits. To meet<br />

the nutritional, environmental and economic<br />

demands of consumers, manufacturers must<br />

innovate to extract maximum value from raw<br />

materials and the production process.<br />

3. Generational push<br />

Younger consumers, raised in an interactive<br />

digital world, are creating trends and defining<br />

what markets should be providing. For Gen<br />

Z and Millennials, food and brand choices<br />

are important signifiers of lifestyle, beliefs<br />

and values. These demographics have a<br />

strong voice and are used to sharing their<br />

views openly and widely. While health is an<br />

increasingly important purchase driver – as it<br />

also is across older generations – novel and<br />

international flavors are winning the hearts of<br />

a young and experimental audience. These<br />

consumers embrace the new and different,<br />

while being extremely responsive to positive<br />

engagement from brands.<br />

4. Plant-Based: Unlocking a new narrative<br />

The rapid rise of the plant-based sector<br />

has, almost inevitably, hit some roadblocks,<br />

necessitating a refocusing on consumer<br />

demands for high quality, flavorsome products.<br />

No longer merely a mimic, green gastronomy<br />

will blossom as a standalone sector in 2023,<br />

giving brands significant opportunities to<br />

diversify and expand. Consumers still want to<br />

5. Farming the future<br />

Public curiosity for innovative technologies<br />

such as vertical and regenerative farming<br />

is increasing. As well as helping to maximize<br />

flavor, nutrition and yield, these advances can<br />

win consumer support where they are shown<br />

to improve the quality and sustainability of<br />

global food production. Today’s consumer<br />

is increasingly invested in the source of food<br />

as it ties in with major global concerns of<br />

health, sustainability and waste. The welfare<br />

of agricultural workers is equally important,<br />

with 65% of respondents to Innova’s surveys<br />

agreeing they would rather buy fruit and<br />

vegetables from farmer’s markets than large<br />

stores. Brands need to demonstrate how novel<br />

production techniques are benefiting farmers,<br />

people and the planet.<br />

Commenting on the food and beverage<br />

industry’s future direction of travel, Lu Ann<br />

Williams reveals: “At Innova, we have seen a<br />

considerable consumer demand for value<br />

redefined throughout the supply chain, with<br />

creative and flexible approaches to the use<br />

of technology and reducing waste proving<br />

pivotal. With financial concerns a dominating<br />

factor, 2023 is a significant year for new<br />

developments that answer these growing<br />

demands. Based on our consumer and market<br />

research, our Top Trends deliver insights to<br />

support brands as they innovate and grow.”<br />

Top Ten Trends for 2023, including opportunities<br />

in the following areas:<br />

6. Quick Quality<br />

7. Devouring Digital<br />

8. Revenge Spending<br />

9. Unpuzzle Health<br />

10. Positively Imperfect<br />

6 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

<strong>Food</strong> <strong>ingredients</strong> industry meets<br />

in Paris for FI Europe <strong>2022</strong><br />

Leading <strong>ingredients</strong> trade show Fi & Hi Europe all set to welcome<br />

more than 20,000 visitors from around the world.<br />

Fi & Hi Europe returns to France this year. From <strong>December</strong><br />

6 to 8, the leading <strong>ingredients</strong> fair will be held for the first time<br />

at the Paris Expo Porte de Versailles exhibition centre. More<br />

than 1,200 exhibitors - from leading <strong>ingredients</strong> manufacturers<br />

to highly specialized startups - will present themselves in four<br />

halls. The face-to-face exhibition will be complemented by a<br />

comprehensive online offering. A broad conference programme,<br />

as well as the renowned Innovation Awards and Startup.<br />

Innovation Challenge, will complete<br />

the trade show experience<br />

In the heart of Paris, Fi & Hi Europe is set to<br />

attract exhibitors and attendees from more<br />

than 135 countries around the world. The<br />

new Paris Expo Porte de Versailles location<br />

is within walking distance of many hotels,<br />

restaurants and bars, making logistics<br />

easier and the event more visitor-friendly<br />

than ever before. Many leading ingredient<br />

8 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

manufacturers have already confirmed<br />

their participation in Paris, including ADM,<br />

Beneo, Brenntag, Cargill, DSM and Ingredion.<br />

In addition to well-established companies,<br />

many new players have also announced<br />

their intention to present their solutions to<br />

the industry. In addition, there will be more<br />

country pavilions this year than ever before.<br />

Digitally enabled event concept<br />

This year, Informa Markets is focusing on<br />

a technologically enhanced hybrid show<br />

concept. The combination of online and<br />

face-to-face events offers participants the<br />

best of both worlds, including a wide variety<br />

of live and on-demand content as well as<br />

data-driven networking options. All exhibiting<br />

companies have their own online profile,<br />

allowing them to find relevant contacts,<br />

network and set up virtual or face-to-face<br />

meetings before the event. A smartphone app<br />

also facilitates on-site lead generation.<br />

“We look forward to welcoming visitors<br />

and exhibitors from around the world to an<br />

event that no one in the <strong>ingredients</strong> industry<br />

should miss,” says Julien Bonvallet, Group<br />

Brand Director at Informa Markets. “After Learn<br />

months of restriction and uncertainty, many<br />

people have a great need for face-to-face<br />

meetings. But even those who prefer to<br />

participate online can do so easily thanks to<br />

our technical solutions.”<br />

Multifaceted conference programme<br />

The online event will begin on 28 November,<br />

the week before doors open at Paris Expo<br />

Porte de Versailles. It offers an extensive<br />

conference programme covering the<br />

hottest topics in the industry, with a focus<br />

on plant-based nutrition, health & wellness,<br />

NEW<br />

VENUE<br />

Online<br />

In-Person<br />

and reformulation. In addition, interested<br />

participants 28 Nov - 8 Dec will find <strong>2022</strong> a wealth 6 - 8 of Dec information <strong>2022</strong> on<br />

From Anywhere Paris, Expo Porte de Versailles<br />

application areas that are currently trending –<br />

Online France<br />

such as baked goods, snacks, dairy products<br />

and dairy alternatives. Overall, the conference<br />

programme includes more than 55 expert<br />

sessions on-site and online, giving global<br />

audiences access to invaluable knowledge.<br />

The platform Fi Global insights provides a lot<br />

of additional information as well as exclusive<br />

reports covering the following topics:<br />

• Protein<br />

• Dairy and Dairy Alternatives<br />

• Snacks, Backery and Confectionery<br />

• Plant-based<br />

• Sustainability<br />

• Beverages<br />

Join<br />

the biggest<br />

EU ingredient event<br />

this <strong>December</strong><br />

Market products in the spotlight<br />

On-site, the New Product Zone in cooperation<br />

with Innova Market Insights offers an<br />

extensive selection of the most innovative<br />

products, showcased alongside insightful<br />

information. It features product innovations<br />

from leading industry players and provides<br />

the perfect opportunity to give new<br />

<strong>ingredients</strong> the introduction to the market<br />

more at that they deserve. A popular area for visitors<br />

bit.ly/istmag and the press, this feature has become a<br />

trendsetting spot for the nutrition industry.<br />

Fi Europe Innovation Awards<br />

The renowned Fi Europe Innovation Awards<br />

will once again be adding extra value to<br />

the trade show. With one exception, the<br />

awards will only be presented among Fi<br />

Europe exhibitors: The new “<strong>Food</strong> Training &<br />

Education” category is also open to nonexhibitors.<br />

This award is intended to recognise<br />

a company, institution or organisation that<br />

contributes to better consumer health,<br />

for example, through an educational<br />

initiative or a pioneering approach. The<br />

“Sustainability Innovation Award” recognises<br />

environmentally, economically or socially<br />

sustainable approaches and practices in<br />

the food and beverage industry. Companies<br />

that create equal opportunities in the<br />

work environment receive the “Diversity &<br />

Inclusion Innovation Award”. The “Plantbased<br />

Innovation Award” acknowledges<br />

alternatives to animal products and is given<br />

for the best ingredient or application. In<br />

the “Sensory Innovation” category, the<br />

Fi2235 Paris ads 206x276 mm.indd 1 24-06-22 10:49<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

9

NEW<br />

VENUE<br />

Online<br />

In-Person<br />

award is for an ingredient or process that<br />

improves 28 Nov the - 8 Dec overall <strong>2022</strong> sensory 6 - 8 properties Dec <strong>2022</strong> of<br />

From Anywhere Paris, Expo Porte de Versailles<br />

foods or beverages. The “Health Innovation<br />

Online France<br />

Award” honours an ingredient or process<br />

that provides a health benefit. The “<strong>Food</strong><br />

Tech Innovation Award” goes to companies<br />

that have developed innovative processes,<br />

packaging or waste reduction solutions.<br />

The decision as to who receives awards is<br />

made by industry experts from the fields<br />

of consulting, management, product<br />

development and trade media. Prof. Colin<br />

Dennis, Chairman of the Board of Trustees of<br />

the IFIS organization and member of the Board<br />

of Trustees of the British Nutrition Foundation,<br />

will again chair the jury this year. The winners of<br />

all categories will be announced during Fi & Hi<br />

Europe at a ceremony on <strong>December</strong> 6.<br />

Join<br />

the biggest<br />

EU ingredient event<br />

this <strong>December</strong><br />

Award for innovative startups<br />

The Fi Global Startup Innovation Challenge<br />

also enables young companies to present their<br />

innovative concepts, products and ideas to<br />

an international audience of experts, major<br />

companies and sponsors. All companies<br />

founded no more than five years ago are<br />

Learn eligible to participate. They can apply in one<br />

more at or more of the following categories:<br />

bit.ly/istmag • Most innovative ingredient for food or<br />

beverage<br />

• Most innovative plant-based or alternative<br />

ingredient<br />

Fi2235 Paris ads 206x276 mm.indd 1 24-06-22 10:49<br />

• Most innovative processing technology<br />

• Most innovative service, technology or digital<br />

solution for the food and beverage industry<br />

Finalists and winners will have access<br />

to the Startup Lounge, where they can<br />

present their products and solutions on the<br />

Innovation Hub stage, and network with<br />

industry representatives. Both the pitches<br />

and the award ceremony will also be<br />

streamed via the Fi Europe online platform<br />

and remain permanently available.<br />

Winners will have a choice of several<br />

attractive prizes: A fully equipped booth<br />

at Fi Europe next year, a comprehensive<br />

online marketing package or an individual<br />

mentoring programme. The latter<br />

can be coaching, for example, or the<br />

implementation of a pilot project, or it can<br />

include access to corporate collaborations<br />

and business accelerator programmes.<br />

In addition to the Innovation Hub, visitors<br />

will find the new Sustainability Hub at the<br />

exhibition, which focuses on sustainable<br />

food solutions along the entire value chain.<br />

Here visitors will find information on food<br />

waste, circular economy, regenerative<br />

agriculture and many other topics. Finally,<br />

the Women’s Networking Breakfast,<br />

sponsored by DSM, Lunch & Learn and<br />

other events are perfect for building a<br />

professional network.<br />

10 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

Transforming global food<br />

production to maximize<br />

food safety and minimize<br />

food loss by making sure<br />

Every Resource Counts.<br />

www.tomra.com/food<br />

TOMRA 5B<br />

TOMRA 5C

IFF excels in innovation<br />

for a better world<br />

As a global brand in food, beverage, health,<br />

biosciences and sensorial experiences,<br />

IFF is an international collective of thinkers<br />

who partner with customers to bring tastes,<br />

experiences, <strong>ingredients</strong> and food solutions<br />

for products the world craves.<br />

We have recently had a chance to meet with<br />

Helga Moelschl, VP, Regional President of the<br />

brand in Dubai at their legendary stand in<br />

Gulfood Manufacturing. Having a very high<br />

traffic, with people hardly able to find place<br />

to stand in the booth, we managed to sit<br />

with Helga and talk about the internationally<br />

acknowledged fame and success of IFF. Our<br />

visit ended with an impressive naturalistic tour<br />

which we had never experienced before. Full<br />

text of the interview follows:<br />

Helga Moelschl,<br />

Regional President AMETI, Nourish, IFF<br />

12 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

Esra Yalcin, Customer Experience Marketing Lead – AMETI,<br />

at the event seminar discussed future disruptions and what’s next for food industry.<br />

As a supplier of a wide range of products<br />

such as food and beverage, fragrance, home<br />

and personal care, and health and wellness,<br />

IFF has been operating in various industries.<br />

With our FB magazine, we would like to talk<br />

only on the food and beverage part of your<br />

company. What is your position in the FB<br />

industry in your specialty area?<br />

We are an international collective of thinkers<br />

who partner with customers to bring tastes,<br />

scents, experiences, <strong>ingredients</strong> and solutions<br />

for food products the world craves. Our<br />

legacy combines market-leading, innovative<br />

businesses from across food, beverages,<br />

health, biosciences and sensorial experiences<br />

In a world filled with hunger for more, for better<br />

and for healthier – we are here to nourish<br />

it. We nourish by growing relationships with<br />

customers of all shapes and sizes, fuelling<br />

them with an end-to-end process and<br />

comprehensive portfolio across categoriesbakery,<br />

bars, confectionary, dairy, beverage,<br />

culinary and snacks. We nourish by uniting<br />

creativity and science to provide what’s<br />

essential and beyond what’s expected.<br />

do they bring in terms of health, environment<br />

and sensorial experience. <strong>Food</strong> and beverage<br />

(F&B) manufacturers are now required to<br />

foresee evolving trends and how to better<br />

meet changing consumer expectations.<br />

IFF leverages PANOPTIC- a proprietary tool<br />

that affords a 360°, outside-in and insideout<br />

approach to deriving consumer insights.<br />

It identifies the most impactful shifts and<br />

dynamics shaping the short, mid and long-term<br />

future of the food industry across categoriesbeverage,<br />

dairy, snacks and bakery.<br />

By enlisting external trend and foresight<br />

partners, advanced analytics, in-house<br />

experts, and proprietary research, the<br />

PANOPTIC allows us to innovate and make<br />

As a member of a global trend-setting brand,<br />

how could you read the future trends in the<br />

food industry?<br />

Consumers today want to know what they are<br />

consuming- that is the <strong>ingredients</strong> used in food<br />

and drinks and what kind of value-addition<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

13

strategic decisions creatively through a<br />

shared understanding of the most influential<br />

trends re-shaping the world.<br />

How do you cope with ever-changing<br />

consumer needs? Is that the professionality<br />

of your R&D department or do you have other<br />

factors as well?<br />

F&B manufacturers are looking for food<br />

solutions which promise convenience and<br />

value more than just single flavors, <strong>ingredients</strong><br />

and complex in-house formulations. They<br />

need partners who are agile, commercially<br />

savvy, and well-networked. Backed by our<br />

PANOPTIC framework we study and let the<br />

insights define the drivers for innovation and<br />

concepts. Co-creation is an integral part of<br />

the entire process as we work closely with<br />

our customers end-to-end, to create marketready<br />

solutions and recipes.<br />

Our success is built on a foundation of research<br />

and development, where our experts are<br />

continuously working on expanding the portfolio<br />

of flavors and <strong>ingredients</strong>, bringing in processes<br />

that ensure the highest quality and delivery<br />

systems. This entails PANOPTIC and IFF PRODUCT<br />

DESIGN frameworks which offer not only strong<br />

market insights to address customer needs, but<br />

also end-to-end product design approach,<br />

featuring an extensive portfolio which includes<br />

flavors and colors, functional <strong>ingredients</strong>,<br />

emulsifiers, hydrocolloids, enzymes and<br />

inclusions for products across food categories.<br />

Ultimately, IFF has a global network of food<br />

scientists and technologists, and our broad<br />

range of technologies across flavors and<br />

<strong>ingredients</strong> help customers in all regions to<br />

create products with improved nutritional<br />

profiles, better taste and texture.<br />

14 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

When we talk about sustainability, sensitivity<br />

for the environment, and protecting our nature,<br />

where does IFF stand at this point?<br />

As reflected in IFF’s nature inspired zones at<br />

the booth in Gulfood Manufacturing show,<br />

we recognize importance of evaluating<br />

environmental impact. We develop solutions<br />

that are good for customers, consumers, and<br />

the environment, because we know that this will<br />

allow us to support wider net zero ambitions and<br />

help customers realize their own ESG targets.<br />

IFF has several innovation programs such as<br />

RE-IMAGINE WASTE TM and Upcycle (showcased<br />

in our Planet First Ocean AR zone), new plant<br />

proteins that support the replacement of animalbased<br />

products, antioxidants and antimicrobials<br />

that extend shelf-life, and upcycled flavor<br />

extracts like citrus that reduce food waste, are<br />

just some of the many examples.<br />

Is there anything that you would you like us to<br />

highlight in the interview?<br />

As a global industry leader, we recognize our<br />

role as pioneers of food innovation. With our<br />

expanded flavor & ingredient portfolio and<br />

product design approach, we have merged<br />

science & creativity into our entire process,<br />

from conceptualization to commercialization<br />

in collaboration with our customers. We<br />

create new sensorial experiences for our<br />

partners that are value optimized, enhance<br />

nutrition, have local taste profiles and simplify<br />

manufacturing processes— while evaluating<br />

environmental impact.<br />

Our strong market insights, consumer<br />

mapping and a proper regulatory procedure,<br />

further future-proofs our offerings and sets<br />

trends that are aligned with and support<br />

consumer needs where taste, health, nutrition<br />

and well-being are concerned.<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

15

SAIREM’s MW and RF technology<br />

is 100% electric and therefore<br />

produces no CO2 emissions and<br />

consumes 50% less energy<br />

compared to traditional heat<br />

treatment processes.<br />

Eco-friendly, energy<br />

saving, hygienic:<br />

efficient sanitisation<br />

with microwave<br />

and radio frequency<br />

systems by SAIREM<br />

SAIREM, a world-leading<br />

specialist in microwave<br />

(MW) and radio frequency<br />

(RF) industrial solutions<br />

based in Lyon, France, will<br />

showcase the company’s<br />

sanitisation technologies<br />

at FIE, <strong>Food</strong> Ingredients<br />

Europe, from 6-8 <strong>December</strong><br />

<strong>2022</strong>. The company will<br />

highlight innovative systems<br />

which are suitable for<br />

either decontamination of<br />

<strong>ingredients</strong> such as powders,<br />

spices, peppercorns,<br />

flours, and nuts etc. or as<br />

disinfestation of plant-based<br />

food and <strong>ingredients</strong> such<br />

as, cereals, soft wheat and<br />

many more. Responding<br />

to client needs, the French<br />

company has developed<br />

highly efficient processes<br />

to produce <strong>ingredients</strong> that<br />

are healthy, clean, and<br />

fully compatible with the<br />

requirements of organic<br />

farming certification.<br />

Chemical free destruction<br />

of potentially contaminated<br />

<strong>ingredients</strong><br />

Decontamination with Sairem<br />

RF and MW systems enable<br />

the complete destruction of<br />

mould, yeast, and bacteria,<br />

without the use of toxic<br />

chemical products. The use<br />

of not allowed gas was one<br />

of the most cited reasons<br />

for product withdrawal<br />

in Europe the last years.<br />

This is a major advantage<br />

for food processors and<br />

suppliers serving the<br />

health -and environmentconscious<br />

consumers of<br />

today. Sairem’s systems are<br />

ideal for superfood trend<br />

products and <strong>ingredients</strong><br />

to produce plant-based<br />

protein alternatives. Valuable<br />

<strong>ingredients</strong> such for example<br />

nuts are treated with extreme<br />

care, therefore resulting in<br />

a high-quality end product<br />

and reduction of 4-5 Log.<br />

The efficient RF and MW<br />

process, which only lasts a<br />

Sylvain Tissier,<br />

Business Development<br />

Manager at SAIREM<br />

few minutes, ensures that<br />

each ingredient is quickly<br />

and uniformly brought to<br />

the required temperature.<br />

As the processing time is so<br />

short, there is no alteration of<br />

the physical, chemical, and<br />

organoleptic properties - all<br />

product characteristics are<br />

perfectly preserved. Other<br />

successful applications<br />

include peppercorns (3.4 Log<br />

reduction) or maize starch<br />

powder (6,87 Log reduction).<br />

RF and MW technology<br />

for disinfestation<br />

from egg to insect<br />

Many high-quality <strong>ingredients</strong><br />

are exposed to the risk of<br />

contamination by parasites,<br />

and in particular larvae,<br />

moths, and beetles. By the<br />

implementation of Sairem’s<br />

RF and MW technology,<br />

parasites and microorganisms<br />

are deactivated<br />

by short, homogenous<br />

exposure to a microwave<br />

field in a temperaturecontrolled<br />

processing cavity.<br />

For example, products<br />

such as dates, whose high<br />

sugar content makes them<br />

particularly vulnerable to<br />

moths and beetle larvae, the<br />

speed of the process ensures<br />

perfect disinfestation while<br />

preserving all organoleptic<br />

properties.<br />

16 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

Sairem assigned French<br />

technical institute ARVALIS<br />

to conduct a study on the<br />

effectiveness of weevil<br />

eradication by applying<br />

Sairem’s microwave heat<br />

treatment. The treatment<br />

tested had excellent<br />

disinfestation results of adult<br />

weevils and their offspring.<br />

Fast, energy-saving,<br />

cost-efficient<br />

The low maintenance<br />

and cost-effective Sairem<br />

systems can process large<br />

amounts of product either in<br />

batches or in a continuous<br />

process in tunnels or the<br />

patented tubular system.<br />

MW energy efficiency<br />

and volumetric heating<br />

keep power consumption<br />

at a lower level than<br />

that of other processing<br />

technologies. As Sairem’s<br />

MW and RF technology are<br />

100% electric solutions, they<br />

have no CO2 emission and<br />

consume 50 % less energy<br />

compared to traditional<br />

heat treatment processes.<br />

SAIREM equipment:<br />

innovation and versatility<br />

in action<br />

Not only does this<br />

equipment provide a<br />

speedy, efficient process, it<br />

has the added advantage<br />

of being very compact with<br />

a small floor footprint that<br />

saves space. It is extremely<br />

user-friendly, offering easy<br />

loading and unloading<br />

as well as a colour touch<br />

screen HMI, and a USB<br />

and ethernet connection<br />

for remote control. Apart<br />

from daily cleaning, there<br />

is no need for regular<br />

maintenance, and it<br />

complies with all hygiene<br />

regulations and standards.<br />

Sylvain Tissier, Business<br />

Development Manager at<br />

Sairem, explains: “Sairem<br />

systems are extremely<br />

versatile and efficient. They<br />

can be used for sanitising in<br />

the role of decontamination<br />

and disinfestation. We have<br />

designed them to provide<br />

fast and effective processes,<br />

ensuring high-performing,<br />

cost-saving results.”<br />

SAIREM offers standardised<br />

systems as well as systems<br />

specifically adapted to<br />

customer requirements.<br />

Hall 4 Stand H105 Paris<br />

6-8 <strong>December</strong> <strong>2022</strong>

PARKİM GROUP A NEW JOURNEY HAS BEGUN:<br />

FLAVOR PRODUCTION AND<br />

FOOD INGREDIENTS DISTRIBUTION<br />

Established in 1979, PARKİM GROUP increases its business activities now dwelling into<br />

a new journey with FLAVOR PRODUCTION and FOOD INGREDIENTS DISTRIBUTION under<br />

PARKİM FLAVORS AND FOOD INGREDIENTS<br />

PARKİM GROUP, manufacturing fragrances and<br />

lotion pumps as well as distributing chemicals<br />

under broad portfolio brings forward its more<br />

than 50 years’ experience now to food industry.<br />

The second generation director, MSc Chemical<br />

Engineer İpek Müstecaplıoğlu explains the<br />

investment process with these words:<br />

“As we set out on this path, our goal was<br />

to convey the professional vision of Parkim<br />

Group to Parkim Flavor & <strong>Food</strong> Ingredients<br />

through flavors production and food<br />

<strong>ingredients</strong> distribution. As in every business<br />

line, our claim is to serve our business<br />

partners with a world-class service quality.“<br />

Extensive market research<br />

İpek Müstecaplıoğlu stated that they had<br />

gone through a very long R&D and feasibility<br />

process before starting this journey, and it<br />

was very important for them to establish<br />

the right team in this process. Today, we<br />

work in coordination with our experienced<br />

flavorists and also with the leading<br />

international consultant professionals from<br />

abroad. Production equipped with the<br />

latest technology we have established. With<br />

our facility and R&D laboratory areas, we<br />

provide services to our customers on flavor<br />

production and food <strong>ingredients</strong>.<br />

18 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

International quality standards and regulation<br />

Flavor production of Parkim Flavor&<strong>Food</strong><br />

Ingredients, takes place at the new Production<br />

facility in Gebze Organization Zone. Considering<br />

the sensitivity of <strong>Food</strong> in quality and certification,<br />

our company acts within the scope of the FSCC<br />

22000 food safety management system and<br />

can submit the necessary documents such<br />

as ISO, GMP, HALAL, KOSHER to its business<br />

partners. The R&D team, which also follows the<br />

constant update of the regulations, can provide<br />

the necessary certifications according to the<br />

demands of especially export and foreign<br />

markets, and constantly supports its own team<br />

with trainings in this regard.<br />

Innovative touches to timeless flavors<br />

Certain classic flavors of our company,<br />

which has a wide flavor portfolio especially<br />

in the liquid dessert group, stand out with<br />

their innovative touches. Our vision here is to<br />

modernize these flavors, which we can define<br />

as timeless as a new player in the sector, with<br />

strategies and trends that are in line with the<br />

expectations of a newer generation. We aim to<br />

bring innovation to your world by reconstructing<br />

classic tastes with modern touches and to grow<br />

together. At the same time, today, especially<br />

the Z generation loves to experience and share<br />

brand new experiences with innovative different<br />

flavors. We are developing different flavors<br />

such as aronia, passionflower, lychee, orange<br />

blossom, sakura in line with this trend. We are<br />

very happy to travel with them on their journey.<br />

Integrative service to the food industry: <strong>Food</strong><br />

Ingredients Distribution<br />

İpek Müstecaplıoğlu stated that they first<br />

entered the sector with liquid flavors; Liquid<br />

flavors appeal to the bakery, chocolate,<br />

confectionery, ice cream and beverage<br />

industries. Our forward-looking investments<br />

continue rapidly and we aim to use different<br />

technologies in time. In addition to our flavor<br />

production, we try to meet these demands<br />

by importing some food <strong>ingredients</strong> that<br />

our customers use during production, by<br />

keeping stocks and on the basis of exclusive<br />

distributions. These consist of general and some<br />

more qualified special food raw materials such<br />

as sunflower lecithin, fibers, proteins.<br />

At the same time, the concept of plantbased<br />

is one of the new topics that have<br />

entered our lives today. We bring special raw<br />

materials suitable for this category and offer<br />

them to our customers. Some of them are<br />

pea protein, wheat fiber, natural antioxidants,<br />

which can be used in vegan products, oat<br />

concentrates that can be used in plant-based<br />

milk production in the beverage industry,<br />

sugar reduction. Raw materials such as<br />

fructo-oligosaccharide (FOS), a prebiotic fiber<br />

that enables the development of products<br />

that support the healthy concept of the end<br />

consumer. We are happy on behalf of our<br />

country, especially because we contribute<br />

to the use of prebiotic fiber instead of sugar<br />

and sugar-derived products, which are now<br />

generally accepted as harmful to health.<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

19

Dehydrated potato market<br />

sheds light on changing<br />

consumer habits<br />

The value-added version of the potato is preparing to appeal to the palate<br />

with its different varieties and colors. The dehydrated potato market<br />

is creating a new alternative that is ready to make moves determined to<br />

impress consumers in terms of flavor and health integrity, unlike other uses.<br />

The process of drying and grinding starchy<br />

root vegetables has been widely approved<br />

around the world, mainly because of its<br />

convenience and portability. Dehydrated<br />

potatoes in particular find application in a<br />

variety of end uses, making them a versatile<br />

product. According to its shape, dehydrated<br />

potatoes are available as flakes, sliced and<br />

chopped pieces, and powder and granules,<br />

which have a variety of different applications<br />

in food processing and preparation.<br />

Dehydrated potatoes are gaining popularity<br />

as a food additive due to their thickening<br />

and binding properties. Dehydrated potato<br />

products have also gained popularity in<br />

recent years as food additives, as they<br />

add nutritional value to various foods. The<br />

functional and nutritional properties of<br />

dehydrated potatoes, combined with the<br />

convenience factor, have led to its rapid<br />

adoption, which has had a positive impact<br />

on the growth of the global dehydrated<br />

potato products market.<br />

Dehydrated potato products are processed<br />

food products made from whole, raw potatoes<br />

that are cleaned, peeled, sliced, precooked,<br />

cooled, cooked, mashed and either drum dried<br />

into flake form or air dried into granule form.<br />

Of the various forms in which dehydrated<br />

potato products are available, the most<br />

popular is potato flakes. The segment is<br />

expected to expand at a moderate CAGR<br />

20 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

of 4% in value. will remain<br />

at the top of the table<br />

throughout the forecast<br />

period.<br />

Although the potato,<br />

which has different types,<br />

is widely used in the world,<br />

it is generally in the<br />

form of frying, but<br />

the increasing<br />

health awareness<br />

completely changes<br />

this perception. The<br />

dehydrated potato type<br />

is very popular thanks to<br />

its non-fat structure and its<br />

contribution to the alternative<br />

snack market.<br />

Purple dehydrated potatoes are very<br />

popular!<br />

Potato varieties used in many different types<br />

such as agata, bintje, charlotte, desiree and<br />

monalisa also come to the fore with their<br />

colorful structures and flavors. The purple<br />

potato, which is used in various parts of<br />

Europe, has already<br />

started to take its<br />

place on the menus of<br />

new generation snack<br />

restaurants.<br />

This potato interpretation,<br />

especially served with<br />

parmesan and truffle, is very<br />

popular with consumers. It is<br />

known that the red potato<br />

is more popular in the<br />

Americas, followed by<br />

durabo and lady<br />

rosetta.<br />

Large food<br />

companies<br />

continue their<br />

production activities<br />

without slowing down for dried<br />

potatoes prepared through special<br />

processes. Producers, prepared to meet the<br />

demanded quantities regardless of large<br />

restaurant chains and local restaurants,<br />

started to expand their facilities and increase<br />

their potato exports in this area.<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

21

Copyright: Glatt<br />

Figure 1: Spray agglomeration, spray granulation, microencapsulation<br />

and film, lipid and hotmelt coating give powders and liquids improved<br />

properties for easier handling in diverse applications.<br />

Fluid bed and spouted bed technologies<br />

Optimising functional <strong>ingredients</strong><br />

for enhanced nutrition<br />

Fluidised bed and spouted bed processes by Glatt offer manufacturers almost<br />

unlimited possibilities in terms of optimised particle design and the functionalisation<br />

of <strong>ingredients</strong>, the properties of which can be fine-tuned using spray granulation,<br />

agglomeration, microencapsulation and film, lipid and hotmelt coating.<br />

Consumer demand for fortified products is<br />

constantly growing and has been well received<br />

by end users. The form in which health-promoting<br />

probiotics, dietary fibres or antioxidants are<br />

consumed depends on both the preferences<br />

and everyday habits of the individual. Whatever<br />

the format, though, an universal requirement is<br />

that functional <strong>ingredients</strong> must be stable during<br />

storage, precisely dosed, dissolve quickly, are well<br />

bioavailable or have a depot effect.<br />

22 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

Fluidised bed and spouted bed processing is<br />

ideally suited to the large-scale production<br />

of these <strong>ingredients</strong>. In many branches of<br />

the industry, these technologies are used to<br />

agglomerate powders, dry liquid <strong>ingredients</strong><br />

into granules or pellets, encapsulate them in<br />

microcapsules and, if required, encase them<br />

in a functional coating (Fig. 1).<br />

Fluidised bed principle<br />

Both fluid bed and spouted bed technologies<br />

are based on the principle of fluidising particles<br />

using an upward-flowing process gas (Fig. 2, 3).<br />

Also used to bulk dry a variety of materials, both<br />

technologies make the process more efficient<br />

by suspending the material to be dried and<br />

exposing its entire surface to the process gas.<br />

Spray granulation:<br />

from liquids to granules in a single process step<br />

Fluid bed spray granulation is an efficient way<br />

to convert liquid raw materials directly into<br />

free-flowing, compact and dust-free granules.<br />

Spray granulation enables granule formation<br />

and release control to be done in a single<br />

step. This enables the drying of liquid food<br />

additives - such as stabilisers, flavours, vitamins<br />

or sweeteners - while precisely adjusting their<br />

particle size, residual moisture levels and<br />

solids content, resulting in round pellets with<br />

excellent physical properties.<br />

Microencapsulation:<br />

protection of volatile and sensitive<br />

active substances<br />

Microencapsulation is also based on the<br />

principle of granulation. Valuable substances<br />

that require special protection are often<br />

present in powder or even liquid form. This<br />

encapsulation process is used in particular for<br />

products and ingedients for the food industry.<br />

With the inclusion of an active substance in a<br />

solid matrix, microcapsules provide an ideal<br />

vehicle to control and protect vitamins, flavours<br />

or polyunsaturated fatty acids (PUFAs), as well<br />

as volatile essential oils. In the field of microencapsulation,<br />

Glatt has conducted various<br />

case studies on formulation and process<br />

optimization strategies based on encapsulation<br />

efficiency. Depending on the preferred principle,<br />

based on the properties of the customer’s<br />

active <strong>ingredients</strong> to be encapsulated, a wide<br />

range of available technical equipment can<br />

be customized in terms of cost, efficiency and<br />

formulation properties.<br />

Film, lipid and hotmelt coating:<br />

functional surfaces<br />

Fluidised bed spray coating is the method<br />

of choice when the optimisation of product<br />

properties involves, for example, controlled<br />

release mechanisms, modifying the surface<br />

structure for higher thermal and oxidation<br />

Copyright: Glatt<br />

Copyright: Glatt<br />

Figures 2 + 3: Continuous fluid bed processing: pictured on the left is a top spray option<br />

with four process chambers; on the right is a continuous spouted bed process with a bottom spray option.<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

23

stability and/or masking odours or flavours<br />

associated with certain <strong>ingredients</strong>. Film or<br />

hot-melt coatings are also proven solutions<br />

that enhance important requirements such as<br />

long-term stability, resistance to oxidation and<br />

targeted release. A functional film coating<br />

not only provides a smooth layer that makes<br />

capsules easy to swallow, it also offers a<br />

protective barrier against light and moisture.<br />

Spray agglomeration:<br />

perfect solubility and homogeneous mixtures<br />

Spray agglomeration is used to convert<br />

powdery raw materials into homogenous<br />

easy-to-disperse (instant) products in a single<br />

process step. The process involves spraying a<br />

liquid into a fluidised bed and forming liquid<br />

bridges between the colliding particles. The<br />

liquid bridges are dried and solidified; as such,<br />

the fine powder is transformed into coarser<br />

agglomerates with a larger grain structure and<br />

improved application properties. The stable<br />

bonds reduce the risk of breakage and abrasion<br />

during handling, processing and storage.<br />

Certain formulations can be agglomerated<br />

using water as the binding agent, which<br />

generates sufficient liquid bridges by<br />

moistening and partly dissolving the surface<br />

of the powder. If harder, more stable<br />

particles are required - as a prerequisite for<br />

further processing, for example - this can<br />

be controlled by binder substance viscosity,<br />

process time and temperature profile.<br />

Fluidised bed spray agglomeration is an<br />

important process for substances destined<br />

for solid dosage applications, such as vitamin<br />

formulations and dried probiotics. Like minerals<br />

and micronutrients, their particle structure,<br />

moisture and bulk density must be adjusted<br />

according to the application. When filling into<br />

cans, capsules or sachets, or compressing into<br />

effervescent tablets, reproducible product<br />

properties such as blend uniformity, flowability<br />

and particle size have to be ensured.<br />

From benchtop to industry scale<br />

Available at the company’s technology<br />

centre in Weimar, Germany, Glatt offers a wide<br />

range of laboratory and pilot plant for early<br />

stage trials and testing. For new particle and<br />

product forms, customers benefit from short<br />

development times without having to invest in<br />

new technology or additional personnel (Fig. 4).<br />

State-of-the-art equipment provides a fast and<br />

reliable way to obtain results for feasibility studies,<br />

product requirements and sample quantities<br />

for performance evaluation or marketing. In<br />

addition, up to the plant commissioning stage,<br />

Glatt offers contract manufacturing services that<br />

fill any in-house production gaps and expedite<br />

time-to-market. From initial idea to the finished<br />

product or production plant, the company<br />

provides a flexible and competent interface<br />

throughout the entire value chain.<br />

Further information including examples<br />

for products and installed plants<br />

in selected projects is available<br />

on the newly designed Glatt website:<br />

https://foodfeedfinechemicals.glatt.com<br />

Figure 4: From the product idea to industrial production of functional powders,<br />

granules and pellets including particle design, process development,<br />

scale-up and plant engineering and implementation.<br />

Copyright: Glatt<br />

24 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

foodfeedfinechemicals.glatt.com<br />

Tailored enhancing of your ProducTs<br />

» Homogeneous and dust-free granules from powdery and liquid raw materials.<br />

» Drying and shaping in just one process step by fluidized bed and spouted bed technology.<br />

» Perfect determination of particle properties.<br />

» Maximum options for functionalization.<br />

» Protection of volatile and sensitive substances.<br />

» More performance, stability and safety for application, handling and storage.<br />

Glatt supports your product idea starting at the early stage of the product formulation and<br />

the process development to the scale up and the final production.<br />

Glatt. Integrated Process Solutions.

Immune health still top priority for<br />

functional beverage consumers,<br />

but other needs on the rise<br />

Immune, gut and heart health continue as<br />

important concerns for functional beverage<br />

consumers, while beauty and sports<br />

performance are on the rise, according to new<br />

research by Kerry, the world’s leading taste<br />

and nutrition company.<br />

Kerry surveyed over 10,000 consumers from<br />

18 countries across North America, South<br />

America Europe, Asia Pacific, South Africa<br />

and Australia to learn more about their<br />

changing priorities and preferred <strong>ingredients</strong><br />

in functional and fortified beverages.<br />

The research found that immune support is<br />

still the highest health priority for consumers<br />

and is a particular focus not only in the US<br />

and UK, but also across developing markets<br />

including Guatemala, Brazil, South Africa,<br />

the Philippines and India.<br />

26 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

A total of 53% of global consumers are<br />

interested in beverages containing <strong>ingredients</strong><br />

specific for immune support but want to see<br />

science-backed <strong>ingredients</strong>, citing vitamin<br />

blends, omega-3 fatty acids and probiotics<br />

as the top <strong>ingredients</strong> on their radar. Although<br />

the overall taste experience is vital, the<br />

primary focus of consumers is on the nutritional<br />

impact of these products and the quality of<br />

<strong>ingredients</strong> used in them.<br />

Need states differ by age and life stage<br />

- implying a need for customised and<br />

personalised solutions, with the research<br />

indicating a holistic need to improve inner<br />

and outer wellness. Consumers are also more<br />

proactive and have come to understand the<br />

link between long-term health and nutrition<br />

and achieving their beauty goals. A desire to<br />

address weight management, heart health,<br />

muscle recovery, energy, endurance and bone<br />

health all point to a desire for all-round wellness.<br />

A preference for beverages supporting skin<br />

and hair beauty was more pronounced in<br />

several developing markets (such as the<br />

Philippines, South Africa, Indonesia, India,<br />

Poland, Brazil, Colombia and Guatemala)<br />

and continues to be a priority in leading<br />

markets including the US and UK. New product<br />

launches containing collagen have risen by<br />

19% over the past four years and products<br />

containing biotin have risen by 14% during the<br />

same period (Innova, <strong>2022</strong>).<br />

research, a total of 86% of consumers stated<br />

they would pay a premium for food and<br />

beverages with added functional benefits.<br />

“Consumers today have compounding need<br />

states. While their top priority need states<br />

remained consistent over the years, there<br />

is growing focus on balance - balancing<br />

beauty with digestive support, immunity with<br />

sports performance, as consumers seek their<br />

personalized idea functional and fortified<br />

solution. To win in this space, manufacturers<br />

need to create products that support top<br />

concerns such as immune, digestive, cognitive,<br />

joint and heart health, and include sciencebacked<br />

functional <strong>ingredients</strong> to increase<br />

credibility. Kerry can transform your idea into<br />

a market leading functional beverage or<br />

supplement, with a toolbox of solutions and<br />

<strong>ingredients</strong> from botanical extracts to sciencebacked<br />

<strong>ingredients</strong> like Wellmune ® and<br />

BC30 to help your brand innovate across a<br />

broad number of consumer need states.”<br />

Meanwhile, products geared towards sports<br />

performance, muscle recovery and endurance<br />

are also no longer the preserve of athletes;<br />

they are high on the agendas of many<br />

thousands of “weekend warriors” who are keen<br />

to lead a healthy and active lifestyle.<br />

Potential for innovation<br />

With the global functional beverage market<br />

predicted to grow at 10.49% annually,<br />

reaching nearly $200 billion by 2026 (<strong>Food</strong><br />

Institute 2021), there is ample opportunity to<br />

innovate in this space.<br />

Commenting on the findings, Soumya Nair,<br />

Global Director of Consumer Research and<br />

Insights at Kerry said: “A significant opportunity<br />

exists in the functional and fortified space, with<br />

the conventional line between supplements<br />

and beverages blurring. According to our<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

27

Strict limits for aromatic mineral oil<br />

hydrocarbons (MOAH) approaching<br />

Nutriswiss edible oils already exceed the future purity standard.<br />

As a result of its own sourcing and innovative<br />

processes, Nutriswiss, the Swiss market leader<br />

for speciality and organic edible oils, already<br />

converts contaminated oils into safe food.<br />

In-house laboratory analyses show MOAH<br />

values close to the detection limit after<br />

refining. After alarming investigation results<br />

published by the non-profit organization<br />

<strong>Food</strong>watch 1 , the EU Standing Committee on<br />

Plants, Animals, <strong>Food</strong> and Feed has defined<br />

a level at which foods should be withdrawn<br />

from the market. The guidance values are<br />

expected to be transferred into applicable<br />

limits by the member states from 2023.<br />

For oils and fats, the EU Committee specifies a<br />

MOAH guidance value of 2 mg/kg. In addition,<br />

it sets an MOAH value of 0.5 mg/kg for dry<br />

foods with a low fat/oil content (up to 4%)<br />

and up to 1 mg/kg for foods with a higher fat/<br />

oil content (more than 4%). 2 Several scientific<br />

studies indicate that aromatic mineral oils are<br />

potentially carcinogenic and mutagenic. 3 4<br />

MOAH in edible oils such as rapeseed or palm<br />

can originate from different places, such as<br />

tire abrasion, exhaust gases or machine oil.<br />

In the Nutriswiss laboratory, a comprehensive<br />

key figure profile is created for each oil before,<br />

during and after processing. This clearly shows<br />

that the self sourced materials are significantly<br />

less contaminated on arrival at the plant than<br />

standard market goods, which is also reflected in<br />

the MOAH values. In supply chain management,<br />

Nutriswiss relies on long-term contractual<br />

partners, logistics in ISO containers according<br />

to food grade standards, and its own controls to<br />

ensure the highest raw material quality.<br />

28 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

Gentle refining<br />

For the removal of MOAH, Nutriswiss does not<br />

use time- and temperature-intensive processes.<br />

Instead, the experts rely on physical treatment<br />

using modern distillation technology followed<br />

by mild deodorization. In this way, the formation<br />

of process contaminants is prevented,<br />

whereas MOSH/MOAH, pesticides, polycyclic<br />

hydrocarbons (PAH) and plasticizers such as<br />

DEHP are significantly reduced. Michel Burla,<br />

CEO of Nutriswiss, says: “A fixed limit value for<br />

MOAH is long overdue because contaminants<br />

have no place in any food. The EU guideline<br />

values now provide the political framework<br />

that we already adhere to on a voluntary basis.<br />

Regardless of the new regulations, we take our<br />

responsibility very seriously; the oils and fats that<br />

leave our plant are safe to eat.”<br />

References<br />

1. https://www.foodwatch.org/fileadmin/- INT/mineral_oil/documents/<strong>Food</strong>watch_Mineralo__l_Report_2021_ENGLISH_03A.pdf<br />

2. https://www.eurofins.de/food-analysis/food-news/food-testing-news/eu-guideline-for-moah-infoodstuffs/<br />

3. https://www.efsa.europa.eu/de/efsajournal/pub/2704<br />

4. https://www.efsa.europa.eu/de/supporting/pub/en-1741<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

29

Dubai World<br />

Trade Centre<br />

and DMG<br />

events partner<br />

to develop<br />

new portfolio of<br />

global events<br />

for the food<br />

and hospitality<br />

sectors<br />

The new partnership to build on a stellar<br />

portfolio of business and consumer events<br />

to take the 30-year legacy of shows<br />

like GULFOOD and The Hotel Show to<br />

new markets. DWTC establishes KAOUN<br />

International, a wholly owned subsidiary to<br />

serve as its international events organising<br />

business. Inaugural Saudi <strong>Food</strong> & Beverage<br />

Show & The Saudi <strong>Food</strong> Manufacturing Show<br />

to be held in June 2023, in Riyadh.<br />

KAOUN International, the newly incorporated<br />

event organising company of the Dubai World<br />

Trade Centre (DWTC) and dmg events, the<br />

wholly-owned subsidiary of the Daily Mail and<br />

General Trust plc (DMGT) an international<br />

portfolio of information, media and events<br />

businesses, announced the signing of a joint<br />

venture agreement to develop an international<br />

portfolio in the food and hospitality sectors.<br />

The newly formed company, KAOUN<br />

International, is built upon DWTC’s formidable<br />

record of organising industry-leading events<br />

that have helped establish not just the UAE<br />

but also the Middle East region, as a top<br />

destination for major international business<br />

Matt Denton, President, dmg Events<br />

Trixie LohMirmand, CEO KAOUN International,<br />

EVP Dubai World Trade Centre<br />

30 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

events. Its portfolio of over 20 business and<br />

consumer events, spans across sectors such as<br />

technology, food and hospitality, sustainability,<br />

broadcast and satellite, automotive, talent<br />

development and leisure marine.<br />

As its first international market expansion,<br />

the new joint venture will launch The Saudi<br />

<strong>Food</strong> & Beverage Show& The Saudi <strong>Food</strong><br />

Manufacturing Show in Riyadh from June 20-<br />

22, 2023. The inaugural event will be affiliated<br />

to GULFOOD Global, the world’s largest go-to<br />

event brand trusted by the global F&B industry.<br />

The Hotel Show Saudi Arabia will be rebranded<br />

for September 2023 to include the broader<br />

hospitality, HORECA and interiors markets. dmg’s<br />

existing food and hotel events in South Africa will<br />

also move under the new joint venture.<br />

“The dmg & KAOUN International partnership<br />

combines market leading food and beverage<br />

industry events with international infrastructure<br />

and an existing hotel and hospitality<br />

portfolio.” dmg President Matt Denton said.<br />

“Having grown our regional and international<br />

operations significantly in recent years, dmg<br />

clearly shares KAOUN International’s view of<br />

high-growth opportunities in the region”.<br />

“Developing new markets and providing access<br />

for our global food and beverage business<br />

community to emerging growth markets is<br />

our collective focus,” Trixie LohMirmand, EVP<br />

DWTC and CEO KAOUN International, added.<br />

“Working together, dmg & KAOUN International<br />

will leverage our existing complementary<br />

experience, networks and brands to create<br />

a synergistic portfolio of food, hotel and<br />

hospitality events that offer far greater<br />

opportunities within targeted geographies.”<br />

“Our market leading events have become<br />

centres of excellence in the food, hotel<br />

and hospitality markets and will continue to<br />

act as the gateway to the wider region,”<br />

noted Matt Denton.<br />

Outside of Dubai, dmg & KAOUN<br />

International together will create more value<br />

for their customers, providing them with a<br />

reliable global partner bringing its proven<br />

level of expertise and professionalism to a<br />

host of new and emerging markets.<br />

Embassy Representatives and<br />

Trade officials in Saudi at announcement<br />

of The Saudi <strong>Food</strong> Show Launch.<br />

DECEMBER <strong>2022</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

31

AK Gıda performed<br />

a taste show at Gastromasa<br />

Ak Gıda; With the brands İçim, Président<br />

and Masterini, took part in the International<br />

Gastromasa Gastronomy Conference.<br />

The catering and cooking workshops<br />

prepared with İçim, Président and Masterini<br />

products by the pastry master Chef Sedat<br />

Yaman attracted great attention from the<br />

conference visitors and participants.<br />

Ak Gıda, which produces the most milk and<br />

dairy products in Turkey and is the largest<br />

producer of the sector with its 6 factories,<br />

participated in the VII. International<br />

Gastromasa Gastronomy Conference<br />

and hosted gastronomy professionals and<br />

enthusiasts with its Président, Masterini and<br />

İçim brands at its booth.<br />

The delicious treats prepared by Chef Sedat<br />

Yaman with cream, cottage yoghurt and<br />

cheese varieties, and workshops such as<br />

cheese-filled pasta, butter croissant, and<br />

filled chocolate made with herbal cream<br />

were the focus of attention of conference<br />

participants and booth visitors.<br />

Ak Gıda supported and participated in the<br />

VII. International Gastromasa Gastronomy<br />

Conference that was organized with the theme<br />

of “Sustainability & Bio-Diversity” this year.<br />

Ak Gıda Marketing Director Selin Dora Falay<br />

stated that as Ak Gıda, they continue to develop<br />

quality, nutritious and delicious products in<br />

line with the needs of their consumers and<br />

environmentally friendly packaging in line with<br />

the sustainability principles through their R&D<br />

activities and she continue:<br />

“Our new brand, Masterini, which we<br />

have just introduced to the out-of-home<br />

consumption market, and İçim and Président<br />

brands for consumers also took place. We<br />

find such events beneficial for both industry<br />

professionals and future chef candidates as<br />

well as consumers. Our chef Sedat Yaman<br />

gave tasting shows all day long at our booth<br />

and we saw that cooking is becoming a<br />

passion for more and more people. We will<br />

continue to explain the different usage areas<br />

of our products with such events.”<br />

32 FOOD & INGREDIENTS INTERNATIONAL DECEMBER <strong>2022</strong>

BENEO reduces specific<br />

energy consumption while<br />

increasing production<br />

capacity of chicory root fibres<br />

BENEO, one of the leading manufacturers of<br />