Powertrain International 2023-3

DIESEL OF THE YEAR SCANIA NEXT GENERATION DC13: we’re approaching the awarding ceremony POWER GENERATION K.EY - DPE RIMINI: the MAN D3872 first application MEE DUBAI: Baudouin, Perkins, Volvo Penta EVENTS ISOTTA FRASCHINI MOTORI: CIS, the R&D house is officially open OFF-HIGHWAY CONEXPO-CON/AGG: we had our fill of ideas in Vegas HYUNDAI DOOSAN INFRACORE: chronicles of the birth of a giant KUBOTA: the right cards for America COMPARISONS 7.5 LITERS INDUSTRIAL: an arena for 13. AGCO Core75 is the new entry ELECTRIFICATION SEGULA TECHNOLOGIES: battery, hydrogen, bio-CNG SEA POWERTRAIN BE POWER SOLUTIONS: FPT and Bimotor in Australia COLUMNS Editorial, Newsroom, Automotive, Sustainable Techno, Think Pink, Stellantis

DIESEL OF THE YEAR

SCANIA NEXT GENERATION DC13: we’re approaching the awarding ceremony

POWER GENERATION

K.EY - DPE RIMINI: the MAN D3872 first application

MEE DUBAI: Baudouin, Perkins, Volvo Penta

EVENTS

ISOTTA FRASCHINI MOTORI: CIS, the R&D house is officially open

OFF-HIGHWAY

CONEXPO-CON/AGG: we had our fill of ideas in Vegas

HYUNDAI DOOSAN INFRACORE: chronicles of the birth of a giant

KUBOTA: the right cards for America

COMPARISONS

7.5 LITERS INDUSTRIAL: an arena for 13. AGCO Core75 is the new entry

ELECTRIFICATION

SEGULA TECHNOLOGIES: battery, hydrogen, bio-CNG

SEA POWERTRAIN

BE POWER SOLUTIONS: FPT and Bimotor in Australia

COLUMNS

Editorial, Newsroom, Automotive, Sustainable Techno, Think Pink, Stellantis

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Powertrain</strong><br />

INTERNATIONAL<br />

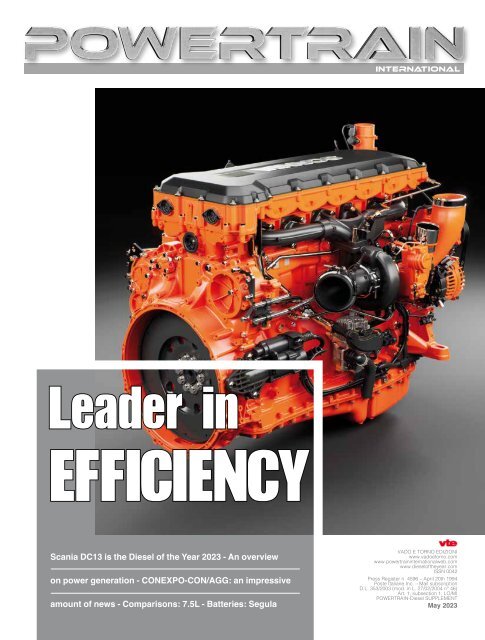

Leader in<br />

EFFICIENCY<br />

Scania DC13 is the Diesel of the Year <strong>2023</strong> - An overview<br />

on power generation - CONEXPO-CON/AGG: an impressive<br />

amount of news - Comparisons: 7.5L - Batteries: Segula<br />

VADO E TORNO EDIZIONI<br />

www.vadoetorno.com<br />

www.powertraininternationalweb.com<br />

www.dieseloftheyear.com<br />

ISSN 0042<br />

Press Register n. 4596 – April 20th 1994<br />

Poste Italiane Inc. – Mail subscription<br />

D.L. 353/2003 (mod. in L. 27/02/2004 n° 46)<br />

Art. 1, subsection 1, LO/MI<br />

POWERTRAIN-Diesel SUPPLEMENT<br />

May <strong>2023</strong><br />

1

MAY <strong>2023</strong><br />

powertraininternationalweb.com<br />

CONTENTS<br />

Our Brand<br />

Our Our Brand<br />

HYUNDAI represents our engine products which aim to provide toplevel<br />

HYUNDAI performance, represents quality, our our engine and services. products which The which strong aim aim to reputation to provide top-<br />

and<br />

toplevel<br />

performance, we already have quality, will and and be services. integrated The The with strong HYUNDAI reputation brand<br />

and<br />

identity heritage<br />

level heritage which<br />

we we we already<br />

will create<br />

have have will<br />

a strong<br />

will be be be integrated<br />

brand value,<br />

with with and HYUNDAI<br />

we will<br />

brand<br />

set<br />

brand<br />

new<br />

goals identity<br />

and<br />

which which<br />

values<br />

will will<br />

building<br />

create create a a on a the<br />

strong<br />

HD<br />

brand brand<br />

Hyundai’s<br />

value, value, and<br />

spirit and we :<br />

we<br />

Human<br />

will will set set<br />

Dynamics<br />

new<br />

new<br />

goals goals and : and Human and values values Dreams.<br />

building on on on the the HD HD HD Hyundai’s spirit spirit : :: Human Dynamics<br />

and and Human Dreams.<br />

Our Our Vision<br />

We We will will relentlessly move<br />

move<br />

We will relentlessly to move<br />

forward to to to revolutionize the<br />

the<br />

forward to revolutionize the<br />

industry and and change the the world<br />

world<br />

industry and change the world<br />

through technological<br />

through technological<br />

transformation and and innovative<br />

transformation services – – – cementing<br />

and innovative<br />

our our status<br />

status<br />

as<br />

services as as a a global a global<br />

– cementing<br />

leader leader in in our<br />

Engine,<br />

status<br />

as Eco-friendly a global leader and and in Electric Engine,<br />

Solution.<br />

Eco-friendly and Electric Solution.<br />

FOLLOW POWERTRAIN INTERNATIONAL ON:<br />

24<br />

GENERIC<br />

ICE<br />

H2 HYDROGEN<br />

kWe ELECTRIC<br />

GAS<br />

18<br />

40<br />

DIESEL OF THE YEAR<br />

06. SCANIA NEXT GENERATION DC13<br />

We’re approaching the awarding ceremony<br />

POWER GENERATION<br />

14. K.EY - DPE RIMINI<br />

The MAN D3872 first application<br />

16. MEE DUBAI<br />

Baudouin, Perkins, Volvo Penta<br />

EVENTS<br />

20. ISOTTA FRASCHINI MOTORI<br />

CIS: the R&D house is officially open<br />

OFF-HIGHWAY<br />

24. CONEXPO-CON/AGG<br />

We had our fill of ideas in Vegas<br />

30. HYUNDAI DOOSAN INFRACORE<br />

Chronicles of the birth of a giant<br />

34. KUBOTA<br />

The right cards for America<br />

COMPARISONS<br />

36. 7.5 LITERS INDUSTRIAL<br />

An arena for 13. AGCO Core75 is the new entry<br />

ELECTRIFICATION<br />

40. SEGULA TECHNOLOGIES<br />

Battery, hydrogen, bio-CNG<br />

SEA POWERTRAIN<br />

42. BE POWER SOLUTIONS<br />

FPT and Bimotor in Australia<br />

COLUMNS<br />

4. Editorial 8. Newsroom 12. Automotive<br />

44. Sustainable Techno 46. Think Pink 50. Stellantis<br />

477, 477, 477, Bundangsuseo-ro,<br />

Bundangsuseo-ro, Bundang-gu,<br />

Bundang-gu, Seongnam-si,<br />

Seongnam-si, Gyeonggido,<br />

Republic do,<br />

Gyeonggido,<br />

Gyeonggido,<br />

Republic Republic of of<br />

of<br />

Korea of Korea<br />

Korea<br />

Korea (13553) (13553)<br />

(13553) enginesales@hyundai-di.com<br />

enginesales@hyundai-di.com<br />

477, Bundangsuseo-ro, Bundang-gu, Seongnam-si, Gyeonggido,<br />

Republic of Korea (13553) enginesales@hyundai-di.com<br />

Editorial: There is life on battery planet<br />

Scania and Northvolt, Volta Trucks and Steyr<br />

Automotive, Farasis Energy, Bosch Rexroth<br />

e-Lion, WAE Technologies<br />

3

EDITORIAL<br />

by Fabio Butturi<br />

THERE IS LIFE ON BATTERY PLANET<br />

M SERIES FOR<br />

CRITICAL<br />

PROTECTION<br />

W<br />

hat have we gathered, compared to the March issue,<br />

regarding concrete steps forward in<br />

electrification? On 19 March, Scania announced<br />

the results of the joint tests with Northvolt.<br />

According to the company, in validation tests, the lithium-ion<br />

cell has demonstrated a lifetime resulting in the capacity<br />

to power trucks for 1.5 million kilometers – equivalent to<br />

the truck’s whole lifetime. Produced with fossil-free<br />

electricity in northern Sweden, the cell’s carbon footprint<br />

is approximately one-third that of a comparative industry<br />

reference. Volta Trucks, the French all-electric commercial<br />

vehicle manufacturer and services provider, has confirmed<br />

the start of production of the 16-tonne all-electric Volta Zero<br />

at Steyr Automotive, the company’s partner in contract<br />

manufacturing, in Steyr, Austria. Co-Founder and Chief<br />

Manufacturing and Logistics Officer of Volta Trucks, Kjell<br />

Walöen, said: “The first full production Volta Zero going<br />

into the production line here at Steyr is the most substantial<br />

milestone the company has achieved to date. In just 2.5<br />

years, less than half the time existing truck manufacturers<br />

take, we have moved from launching a concept, through<br />

the engineering, development and quality phases and now<br />

the start of production of the final specification models.”<br />

Farasis Energy, a supplier of high-performance lithiumion<br />

pouch cells, has developed a module design concept<br />

to prevent thermal propagation using its newest generation<br />

of cells (Generation 4).<br />

With a newly developed, single-phase onboard charger,<br />

Bosch Rexroth has made its eLION platform fully<br />

compatible with the North American charging infrastructure.<br />

The company is introducing its high-voltage solutions for<br />

the electrification of mobile working machines to the North<br />

American market at the CONEXPO-CON/AGG construction<br />

fair. The broad range of motors, inverters, gearboxes, and<br />

software also includes a highly effective DC/DC converter.<br />

WAE Technologies launches Elysia, the latest in Battery<br />

Intelligence for the mass market, from the automotive,<br />

commercial vehicle and e-mobility sectors to stationary<br />

energy storage and beyond. Elysia Embedded is a suite<br />

of battery management algorithms that can allow OEMs<br />

to increase range, unlock faster charging, and maximise<br />

battery power.<br />

So, summarizing, power density, mass production,<br />

adaptability to charging infrastructure, battery management.<br />

This is the right direction. We will not make any remarks<br />

on timing or scalability in the short term.<br />

BAUDOUIN M26 M33 M55<br />

kVA: 815 - 4125<br />

RPM: 1500 - 1800<br />

Applications:<br />

ESP, PRP,DCP<br />

POWERKIT M SERIES ENGINES AVAILABLE NOW.<br />

Providing highly-competitive power density for Emergency Standby<br />

Applications. With low fuel consumption and extended mean time between<br />

overhauls, it’s the most trustworthy engine range to serve the power needs of<br />

even the most demanding applications.<br />

DURABLE. ROBUST. BUILT TO LAST. BAUDOUIN.COM<br />

4

DIESEL OF THE YEAR<br />

#SCANIA #AWARDINGCEREMONY #EFFICIENCY<br />

SCANIA NEXT GENERATION DC13<br />

STRAIGHT<br />

ON THE<br />

STAGE<br />

BRAND<br />

MODEL<br />

SCANIA<br />

DW6<br />

I. D.<br />

B x S mm - S/B 130 x 160 - 1,23<br />

N. cil. - dm 3 6 - 12,74<br />

Maximum power kW - rpm 450 - 1.900<br />

Mep at max power bar 22,8<br />

Piston speed m/s 10,1<br />

Maximum torque Nm - rpm 2.969 - 1.400<br />

Mep at max torque bar 29,9<br />

% power at max torque (kW) 56<br />

Torque at max power Nm 2.264<br />

% power at max torque (kW) 96,8 (436)<br />

Work range rpm 500<br />

DETAILS<br />

Specific power kW/dm 3 35,3<br />

Specific torque Nm/dm 3 233<br />

Areal spec. power kW/dm 2 56,53<br />

RULES AND BALANCE<br />

Dry weight kg 1.050<br />

L x W x H mm<br />

1.397x1.157x920<br />

Volume m 3 1,49<br />

Weight/power kg/kW 2,3<br />

Weight/displacement kg/dm 3 82,4<br />

Power density kW/m 3 302<br />

Total density t/m 3 0,70<br />

Displacement/volume dm 3 /m 3 8,55<br />

On Tuesday 16 May, at 5pm, the<br />

Diesel of the Year <strong>2023</strong> award<br />

ceremony is scheduled. Scania’s<br />

Next Generation DC13<br />

will go on air as the testimonial for the<br />

latest generation of the internal combustion<br />

engine. Those Stage V and<br />

Euro 6e engines that find themselves<br />

in the dock, despite being the main<br />

performers of decarbonisation. No<br />

longer are the efficiencies of the obsolete<br />

air-cooled diesel engines, with mechanical<br />

injection, inextricably linked<br />

to piston stresses. The propagation of<br />

the combustion agent and the skilful<br />

management of electronic control have<br />

buffered the release of pollutants at the<br />

writing by up to 98-99% at the top. The<br />

awarding ceremony will be introduced<br />

by our editors. Our publisher organises<br />

a series of awards for innovation and<br />

For the Diesel<br />

of the Year <strong>2023</strong>,<br />

the Scania next<br />

Generation DC13<br />

engine, the official<br />

award ceremony<br />

is approaching.<br />

We will broadcast it<br />

from our television<br />

studios near Milan.<br />

You can watch it<br />

on May 16 th at 5pm<br />

on our website<br />

and social media<br />

channels.<br />

Stay tuned!<br />

sustainability, ranging from Tractor<br />

of the Year, Sustainable Truck of the<br />

Year to Sustainable Bus Awards. The<br />

only way to respond right now to the<br />

demands of decarbonisation is in fact<br />

to reduce exhaust pollutants. An approach<br />

that clashes with the demands<br />

of the European legislator, oriented<br />

towards the imperative of “zero emissions”.<br />

In a scenario of gradual break<br />

from dependence on fossil fuels, the<br />

operation that Scania has accomplished<br />

with the Next Generation DC13 is to<br />

optimise, indeed implement, the efficiency<br />

threshold. More fuel processed<br />

into mechanical energy, less combustion<br />

waste, otherwise taken over by the<br />

after-treatment system. Without delving<br />

too deeply into technical parameters,<br />

there is one figure that certifies the<br />

design aims of Swedish engineering:<br />

power at maximum torque. As many<br />

as 435, out of 450 kilowatts are available<br />

at 1,400 rpm, equivalent to 96.8<br />

percent of the available power. Another<br />

aspect we emphasised earlier, in this<br />

regard, concerns the readiness of the<br />

12.7-litre engine to run on synthetic<br />

and biomass fuels. Another tangible<br />

tile in the mosaic of the propulsion sys-<br />

tem of the future, which must of force<br />

be conjugated to the present time. We<br />

take leave with the words of Magnus<br />

Henriksson, Chief Engineer, who led<br />

the Scania team by the hand in developing<br />

the Super, the DC13’s big brother,<br />

for the Griffin trucks: “Developing a<br />

new engine platform of this magnitude<br />

is a once-in-a-lifetime opportunity for<br />

most engine platform engineers.”<br />

6<br />

7

NEWSROOM<br />

#SOMO #ELECTRIFICATION<br />

SOMO & ELECTRIFICATION<br />

VERY GOOD<br />

BUT...<br />

POWER TO<br />

MAXIMIZE<br />

PRODUCTIVITY<br />

More power with less complexity and less weight. The Cummins<br />

B6.7 engine delivers the productivity you need to keep your<br />

equipment running. The power increases up to 326 hp / 243 kW<br />

and peak torque up to 1014 lb-ft / 1375 Nm, enabling<br />

replacement of engines with higher displacement<br />

with no impact on productivity.<br />

“Electric vehicles are<br />

a good thing, but not if<br />

everybody owns one”<br />

is the balance,<br />

summed up in a<br />

slogan, of the thought<br />

of SOMO expert<br />

Alejandro González<br />

S<br />

OMO, the Dutch centre for<br />

research on multinational corporations,<br />

is trying to have the<br />

big picture about electrification.<br />

“Electric vehicles are part of the<br />

solution to climate change. But the<br />

size and sheer volume of planned EV<br />

production is not sustainable,” said<br />

SOMO expert Alejandro González.<br />

“We cannot consume our way to a<br />

cleaner, greener future. We need fewer<br />

cars, smaller cars, and more sustainable<br />

public transport options.<br />

This should be at the core of EU energy<br />

transition policy.” EU’s approach<br />

pays lip service to reducing demand<br />

for extraction of new raw materials,<br />

but this is belied by its efforts to increase<br />

EU access to the minerals, and<br />

by the focus on using trade and development<br />

policies as leverage.<br />

“The EU is regulating batteries with<br />

one hand but driving demand for minerals<br />

for the same batteries with the<br />

other; this is incoherent as a policy<br />

and continues to treat resource-rich<br />

countries like Argentina, Chile, DRC,<br />

and Indonesia as mere sources of<br />

materials,” said Alejandro González.<br />

While EVs have no tailpipe carbon<br />

emissions, their production generates<br />

serious negative impacts, particularly<br />

in the countries where the minerals<br />

to produce Li-ion batteries are extracted.<br />

The demand for lithium and<br />

nickel is set to skyrocket in the next<br />

five years as a result of mass adoption<br />

of EVs in Europe, the US, and<br />

China. While the adoption of EVs in<br />

these regions is heavily incentivised<br />

by subsidies, tax breaks, and emission<br />

reduction targets, the extraction<br />

of minerals to produce them generates<br />

large amounts of waste. The vast<br />

majority of EVs that will be produced<br />

in the next seven years will sell<br />

to consumers in the US, Europe, and<br />

China, and exclude most of the rest<br />

of the world. Commentators on the<br />

energy and transport transition have<br />

noted that this two-tier picture of<br />

“haves” and “have-nots” adds new<br />

dimensions of global inequality.<br />

“The EU has an opportunity here<br />

— to avoid being responsible for<br />

driving abuses and deep inequality<br />

in the energy transition. But that<br />

opportunity is slipping away,” said<br />

González. “A fundamental shift in<br />

the EU’s paradigm is necessary, fostering<br />

a vision of transport that does<br />

not involve near-universal personal<br />

vehicle ownership in the European<br />

region.”<br />

Finally, González stated: “A just<br />

energy transition is imperative, but<br />

under current policies of the EU, US,<br />

and China, it is out of reach. This has<br />

to change and change fast. We need<br />

to reduce reliance on individual cars<br />

and travel in more sustainable ways.<br />

Moving towards this vision has to become<br />

the core of public policy, and<br />

governments must shift their approach<br />

– and their budgets – to enable,<br />

educate the public about, and incentivise<br />

this paradigm shift.”<br />

8<br />

©<strong>2023</strong> Cummins Inc.<br />

9

NEWSROOM<br />

#ENI #HVO #VOLVOPENTA #UIG #TSO<br />

ENI, SPINELLI GROUP AND HVO<br />

HVO made a step further due to ENI<br />

initiative. Eni Sustainable Mobility<br />

and the Spinelli Group, an integrated<br />

logistics player from Genoa, Italy,<br />

have signed a two-year contract to<br />

power the group’s fleet with HVOlution,<br />

a diesel fuel produced from<br />

100% renewable raw materials. The<br />

Spinelli Group’s fleet includes more<br />

than 300 heavy-duty vehicles, of<br />

which 150 are latest-generation Euro<br />

6d trucks compatible with pure biofuel.<br />

The supply of biofuel to the<br />

Spinelli Group is made possible by<br />

Eni Sustainable Mobility’s network<br />

of retail outlets. The product is now<br />

available in 57 service stations and<br />

by the end of the month it will be<br />

available in 150 sales points in Italy.<br />

The agreement is key to Eni Sustainable<br />

Mobility and shows how the<br />

company can support heavy transport<br />

players like the Spinelli Group<br />

on the path towards decarbonization.<br />

Eni Sustainable Mobility has been<br />

operating since January <strong>2023</strong> and<br />

combines bio-refining, biomethane<br />

and the sale of mobility-related products<br />

in over 5,000 service stations in<br />

Italy and abroad.<br />

C<br />

PENTA GRID<br />

INNOVATION<br />

VOLVO PENTA HAS<br />

ACQUIRED A MINORITY<br />

STAKE IN UTILITY<br />

INNOVATION GROUP (UIG)<br />

Volvo Penta has made a strategic<br />

investment in UIG (Utility<br />

Innovation Group), US-based<br />

specialists in resilient, innovative<br />

utility systems and decentralized<br />

energy solutions. Through this, UIG<br />

and Volvo Penta have the potential to<br />

enhance their collective capabilities,<br />

while jointly creating innovative solutions<br />

and new market opportunities to<br />

advance electric grid infrastructure.<br />

This milestone also provides more<br />

opportunities for mission-critical use<br />

cases, the likes of hospitals and data<br />

centers, alongside a new class of electrical<br />

“prosumers” who both produce<br />

and consume energy in support of the<br />

electrical grid, leveraging renewables<br />

and other on-site energy sources. All<br />

profiles can optimize their energy<br />

usage by connecting energy sources<br />

with battery energy storage systems<br />

(BESS) to reduce reliance on the<br />

grid and build a more resilient energy<br />

ecosystem. Overall, the investment<br />

underscores Volvo Penta’s ambition<br />

as an independent supplier, to scale<br />

net-zero projects together with its<br />

OEM customers at a higher pace while<br />

continuing to strengthen the reliable<br />

portfolio of solutions available to<br />

its customers.<br />

German gas strategy<br />

On March 31 st , the German<br />

gas transmission system<br />

operators (TSOs) presented<br />

their draft Gas Network<br />

Development Plan 2022-<br />

2032. The proposal is<br />

designed to facilitate the<br />

changes needed for the<br />

network to accommodate<br />

the new LNG supplies<br />

into Germany and<br />

Europe. According to their<br />

calculations, the proposed<br />

projects will require some 4.4<br />

billion euros of investment,<br />

1.9 billion of which will be<br />

network expansion projects<br />

for new LNG.<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

CMY<br />

K<br />

V170 G SERIES<br />

10

AUTOMOTIVE<br />

#INTERNALCOMBUSTIONENGINES #EURO7<br />

EURO 7<br />

ARE<br />

YOU<br />

READY?<br />

FOR NOW, INDIA IS COUNTING ON GAS<br />

It takes a bit of training to understand, in the traffic of<br />

Mumbai, what the hell is behind the Toyota Glanza<br />

hatchback, complete with the CNG initials on the tail. In<br />

a country of 1.4 billion inhabitants, with 21 million cars<br />

on the road, the new green frontier – more than electric<br />

motors – is natural gas, which today fuels more than 6<br />

percent of cars on the road. And the compact Toyota is<br />

enjoying some success. It is actually a local rebadging<br />

of the Suzuki Baleno, whose 1.2-liter natural gas-powered<br />

engine delivers 77 horsepower and 98 Nm of<br />

torque. The 7,500 euro list price may seem ridiculous,<br />

but you should take into account that the per capita average<br />

income is 15 times lower than in Italy.<br />

After the pyrotechnics<br />

of statements, a less<br />

catastrophic reality<br />

begins to emerge.<br />

We report some<br />

sentences of Luca de<br />

Meo, Carlos Tavares<br />

and Oliver Blume.<br />

Pascal Canfin:<br />

“It was difficult to<br />

ask manufacturers<br />

to make investments<br />

in electric and heat<br />

engines at<br />

the same time”<br />

There are those who win the Oscar<br />

and those who earn the Legion<br />

of Honour. And, according to the<br />

most mischievous, the honour<br />

awarded by President Macron to Luca<br />

de Meo would not be due to the excellent<br />

work done in the last two years as CEO<br />

of the Renault group. Nor a polite invitation<br />

not to leave the Régie, controlled<br />

by the French State, to take the reins of<br />

Stellantis, as the rumors would have it.<br />

But the prize for his “masterpiece statement”<br />

in taking on the role of president<br />

of Acea, the European Automobile Manufacturers’<br />

Association: “The proposal<br />

for Euro 7 standards, in its current form,<br />

would take away huge human and financial<br />

resources from electrification, just as<br />

other regions of the world are creating<br />

an attractive investment environment for<br />

zero-emission mobility”. Nothing in common<br />

with the bellicose diktat of Carlos<br />

Tavares, CEO of Stellantis, who spoke<br />

openly of “wasting money to adapt products<br />

that will in any case have a short<br />

life” referring to the EU stop to ICEs<br />

starting from 2035. Nor with the drastic<br />

standpoint of Oliver Blume, CEO of the<br />

Volskwagen Group who, ever since he<br />

led Porsche, has been preaching: “we will<br />

decide whether or not to update all our<br />

engines to Euro 7 standards or offer exclusively<br />

electric versions”. A vision denied<br />

by data from the European market<br />

for the first half of 2022, where for every<br />

Volkswagen ID.3 BEV sold, 5 petrol or<br />

diesel Golfs were marketed, despite the<br />

wave of incentives for electric cars that<br />

hit the markets of Germany, France and<br />

Italy. The real problem is that the EU remains<br />

the only market in the world that<br />

will officially abandon internal combus-<br />

tion engines in 2035. Of course, China<br />

has already set the goal of doing so in<br />

2030, as well as Brazil and India, but they<br />

do not go further than that, while Canada<br />

and Taiwan speak of 2040, in the total silence<br />

of the USA, where only California<br />

is evaluating a deadline in 2035. Moreover,<br />

if we add the hypothesis that the Qatargate<br />

scandal could question the green<br />

majority in the European Parliament and<br />

postpone the 2035 deadline, the new<br />

Euro 7 standards find a new light. In fact,<br />

they could prove to be a valuable “framework<br />

regulation”, which, once and for all,<br />

eliminates the tangle of homologation<br />

tricks dragged from directive to directive,<br />

without however asking for impossible<br />

interventions from manufacturers. The<br />

Multimilioner industrial groups that, behind<br />

the smokescreen of press statements,<br />

were ready to set far more stringent limits<br />

on the emissions of their engines. As<br />

the French newspaper Le Monde wrote,<br />

setting the NOx emission limit at 60 mg/<br />

km for Euro 7 was a political choice by<br />

the European Commission, given Acea’s<br />

expressed willingness to go down to 35.<br />

“It was difficult to ask manufacturers to<br />

make investments in electric and heat engines<br />

at the same time”, Pascal Canfin,<br />

president of the Strasbourg Parliament’s<br />

environment commission, commented<br />

in the French newspaper. Who gets the<br />

credit for this? First of all, the European<br />

commissioner for the internal market,<br />

Thierry Breton, who has repeatedly<br />

underlined the strategic and social risks<br />

of euthanizing the ICE. A meaningful<br />

example of the new directive is precisely<br />

the new “single” limit of 60 mg/km<br />

for NOx emissions, which has remained<br />

the same as the Euro 6 standard for pet-<br />

rol car engines and has dropped from 80<br />

for diesel engines. A much more onerous<br />

limit to be respected only for the heavy<br />

vehicle sector, where the costs of devices<br />

for aligning trucks at 60 (56 percent less<br />

than Euro 6) are more easily “spreadable”<br />

on the robust price lists of those<br />

vehicles. Without hiding that two “media<br />

bubbles” are also deflating. The first<br />

concerns the fact that the new RDE (Real<br />

Driving Emission) tests envisage more<br />

stringent conditions for tests run with a<br />

cold engine, limiting the engine heating<br />

stage to the first 1,600 meters. The other<br />

concerns the extension to 240,000 kms of<br />

compliance obligations for anti-pollution<br />

devices, a value that may seem shocking<br />

at first, but in fact aligns Europe with the<br />

USA and Canada, which impose 200,000<br />

miles, making life easier for manufacturers<br />

operating in the global market.<br />

12<br />

13

POWER GENERATION<br />

#BIMOTOR #FPT #GEMINIANI #HYUNDAI #ISOTTA #MAN #NGV #RAYWIN<br />

K.EY - DPE RIMINI<br />

A<br />

GREAT<br />

SHOW<br />

MAN ENGINES & BIOBRENT<br />

At the BioBrent stand, we talk about the MAN E3872 with<br />

the top management. “There is a great demand on the<br />

market for intermediate sizes powered by natural gas;<br />

this was lacking until the previous edition of Ecomondo.<br />

This is a world premiere, which allows BioBrent to extend<br />

its range of products; it is an excellent tool to expand<br />

our clientele. Installed in a plastic packaging company,<br />

this set is aimed at industries that have significant<br />

energy consumption, both electrical and thermal, and<br />

are therefore particularly sensitive to energy efficiency,<br />

food companies, companies in the plastic, chemical<br />

and pharmaceutical sectors. This is an application for<br />

trigeneration uses: the system is custom built to produce<br />

electricity, heat (hot water at 85°) for the process and<br />

refrigeration (water chilled at 8°) to cool the moulds.<br />

All the energy produced is self-consumed within the<br />

company, thus reducing energy withdrawal from the<br />

grid by 85%. The reduction on an annual basis will be by<br />

28%. Among other advantages, it complies with the 250<br />

milligrams/normalNm 3 regulation. Without SCR, it only<br />

has the CO catalyst.”<br />

It was a success for K.EY, for the first<br />

time detached from Ecomondo, in<br />

cohabitation with DPE (Distributed<br />

Power Europe). The E3872 was at<br />

the ETS-MAN stand, where Marianna<br />

Benetti and Klaus Kress explained<br />

to us: “The upgrade took place for E32<br />

and E08, with a 20% hydrogen mixture<br />

(starting from the aspirated stoichiometric:<br />

-23% HC, -1.2% CO, -5.2% CO 2<br />

and -27% HCHO, i.e. formaldehyde. The<br />

lean burn: -17% HC, -21% CO, -11%<br />

CO 2<br />

, - 26% HCHO). The mechanical efficiency<br />

of the 25.8-litre engine is equivalent<br />

to 40.5%, for the 29.6-litre engine it<br />

is 44%”. We talked about the E3872 for<br />

the first time a few months ago, at Ecomondo.<br />

It seems that it is now functional<br />

and very close to us. Isn’t it? “It actually<br />

came off the test bench and found its first<br />

ever application with BioBrent, which<br />

K.EY celebrated its<br />

first separate edition<br />

from Ecomondo with<br />

a success among the<br />

public and exhibitors.<br />

MAN displayed the 700<br />

kW natural gas E3872<br />

in its first application<br />

with BioBrent. At the<br />

DPE, which took place<br />

simultaneously, we<br />

saw, among others,<br />

FPT, Geminiani,<br />

Hyundai, Isotta<br />

Fraschini, NGV and<br />

Raywin<br />

will carry out the field test in early June<br />

(see box). It was presented at the Energy<br />

Dezentral in Hannover in November<br />

2022. Until now, no manufacturer covered<br />

the 700kW power of the methane<br />

range for cogeneration. The PBST turbo<br />

can be opened, the diffuser ring, i.e. the<br />

turbo compressor, is detached from the<br />

architecture to favor flexibility (gas and<br />

biogas), also based on the altitude. There<br />

are two butterfly valves, steel pistons,<br />

Atkinson cycle type camshaft (during<br />

combustion there is a “backflow”: the<br />

intake valve opens to let fresh mixture<br />

into the cylinder). Versions at 1,800 rpm<br />

and with a 20% hydrogen mixture are<br />

planned”. Among K.EY’s start-ups appears<br />

the familiar face of Adela Tucaru,<br />

marketing and communication manager<br />

of NGV <strong>Powertrain</strong>. “We have found<br />

a lot of interest in the hydrogen engine<br />

(presented at Hyvolution Paris together<br />

with FEV, Ed.), both as original equipment<br />

and as a retrofit, globally. The hydrogen<br />

supply chain is also moving to enhance<br />

the circuit of refueling stations. On<br />

the other hand, there are those who still<br />

believe in biomethane as a short-term<br />

solution”. Let’s move to the DPE. There<br />

we find Isotta Fraschini. The COO,<br />

Giovanni Bruni: “K.EY is proving to be<br />

a lively and profitable fair. We have registered<br />

several contacts which confirm our<br />

12 and 16 cylinders as valid alternatives<br />

to the engines of our competitors. Part of<br />

this discussion is the V12 in the Stage V<br />

version, presented at the recent Middle<br />

East <strong>2023</strong>, which widens the perspectives<br />

with respect to emergency uses, lending<br />

itself to continuous and potentially cogeneration<br />

uses. The company invests<br />

in market niches. Declining the product<br />

standard according to customer needs is<br />

part of our DNA, which we also apply to<br />

the industrial engine.”<br />

Bimotor and Valdinoci present the<br />

Raywin range. Valdinoci’s CEO tells<br />

us about the partnership with Bimotor.<br />

“Both Bimotor and Valdinoci are oriented<br />

towards establishing a solid and<br />

structured collaboration, we scrupulously<br />

follow after-sales. We are both characterized<br />

by large stocks and high supply<br />

availability. Since 1935 Valdinoci has<br />

been monobrand, Lombardini first, then<br />

Kohler. Kohler invests in technological<br />

engines, as demonstrated by the resources<br />

spent in Stage V, hybridization and the<br />

purchase of Curtis Instruments, IIIA production<br />

is not as strategic as it has been<br />

in the recent past. The Raywin range<br />

goes from 5 to 60 kVA. The distribution<br />

agreement concerns generation sets, mo-<br />

tor pumps and sprinklers, for the Italian<br />

market.” The participation of FPT Industrial<br />

is shared with the dealer Avoni.<br />

On display are the F34 and F36, Stage V<br />

avant-gardes that allow entry to both the<br />

EU and North American markets. <strong>2023</strong><br />

and 2024 are expected to be two more<br />

years with high orders. “A large market<br />

share remains attractive to the ICE,<br />

linked to PG, for applications with less<br />

than 500 hours of operation.” Socoges<br />

exhibited the D24 by Hyundai Doosan<br />

Infracore, 50 kVA, Stage V. 2022 was a<br />

record year, balanced in all applications.<br />

What does the near future hold for us?<br />

“Some innovations, also for PG” is their<br />

answer. “The first mass production in<br />

2024 is the D34, from 80 to 100 kVA in<br />

prime. Then the DX05, 200 kVA, and the<br />

DX08, 300 kVA. At the top is the DX12,<br />

11.1 litres, Stage V, 400 kVA.”<br />

14<br />

15

POWER GENERATION<br />

#VOLVOPENTA #D17 #MEEDUBAI<br />

VOLVO PENTA<br />

LADIES &<br />

GENTLEMEN,<br />

THE D17<br />

Volvo Penta does not rest on<br />

their laurels. The D17 was<br />

born from the determination<br />

to improve the top of its power<br />

generation range (801 kVA prime<br />

60hz electrical power kVA, 758 kVA<br />

prime 50hz electrical power). The<br />

audience in front of which to cut<br />

the ribbon is the Middle East Energy<br />

exhibition in Dubai. The 17-liter<br />

TWD1744GE industrial genset<br />

engine will help support both the<br />

current demands of industrial customers<br />

as well as their future business<br />

needs. Looking ahead, the<br />

D17 will evolve to enable customers<br />

to transition to significantly lower<br />

emissions utilizing alternative fuels.<br />

What are the design and functional<br />

benefits of this engine? The D17 offers<br />

up to 5% less fuel consumption<br />

In the shade of the<br />

Burj Khalifa tower,<br />

Volvo Penta has<br />

unveiled its ace up<br />

its sleeve for power<br />

generation: the<br />

TWD1744GE, inline<br />

6-cylinder, 17.26 litre.<br />

Kristian Vekas:<br />

“To find something<br />

with equivalent<br />

power density,<br />

you’d have to look<br />

beyond automotivebased<br />

designs”<br />

per kWh than its lower-displacement<br />

D16 sibling. This is largely<br />

the result of recent evolutions in<br />

combustion technology such as the<br />

modernization of the fuel-injection<br />

system with a common-rail design.<br />

An important new feature, which<br />

will also be made available to D16<br />

models, is the option of a viscous<br />

fan to further reduce fuel consumption<br />

and noise emissions. Volvo<br />

Penta further leveraged its existing<br />

power generation platform with the<br />

adoption of the D16’s inline six-cylinder<br />

block as the starting point for<br />

the new design, ensuring the D17’s<br />

basic footprint would remain the<br />

same. The company’s engineers developed<br />

a larger bore engine which<br />

thereby enabled the larger volume.<br />

This paved the way for around a<br />

10% increase in maximum standby<br />

power over the TWD1645GE at<br />

1800 rpm. “Combining this with its<br />

dual-stage turbochargers means the<br />

D17 can provide much higher power<br />

from a smaller envelope, comparing<br />

favourably with larger alternatives,<br />

while offering the additional benefit<br />

of far more economical operation,”<br />

says Kristian Vekas, Product<br />

Manager at Volvo Penta. “To find<br />

something with equivalent power<br />

density, you’d have to look beyond<br />

automotive-based designs – which<br />

will likely add further cost implications.”<br />

Designed to power a variety<br />

of stand-by and prime-power generator<br />

sets, the dual-speed (1500/1800<br />

rpm) D17 is suitable for a wide range<br />

of applications, most notably where<br />

sufficient back-up electrical power<br />

must be always available. Like<br />

all Volvo Penta genset engines, the<br />

new unit therefore complies with the<br />

most-stringent ISO8528 G3 standard<br />

for load acceptance, a measure of<br />

how quickly it can meet power demand<br />

in response to a blackout. The<br />

D17’s low exhaust emissions ensure<br />

compliance with UNECE REG 96<br />

Stage 2 (equivalent to EU Stage II<br />

mobile off-highway requirements)<br />

and it is certified for US EPA Tier 2<br />

Stationary Emergency, enabling it to<br />

be used for supplying a few hours of<br />

back-up power in these highly regulated<br />

regions. Service interval is<br />

set at 10,000 hours. “Our customers<br />

were instrumental in inspiring<br />

the D17’s introduction,” adds Kristian<br />

Vekas. “In addition to wanting<br />

extra power to provide more elec-<br />

tricity, they were keen for it to retain<br />

commonality with the D16 for<br />

seamless integration.” Just to mention<br />

the TWD1645GE sibling, aka<br />

TWD1683GE, the Stage V version of<br />

the 16,1 litres engine, 6 cylinders inline,<br />

is able to provide up to 660 kVA<br />

(528 kWe) at 50hz in prime power<br />

(726 kVA and 581 kWe in stand-by),<br />

and 700 kVA (616 kWe) at 60hz in<br />

prime power (770kVSA and 616<br />

kWe in stand-by). “We’ve leveraged<br />

our D16 platform and capitalized on<br />

its real-world use and testing across<br />

the Volvo Group,” concludes Hannes<br />

Norrgren, President of Volvo Penta<br />

Industrial. “We are taking our power<br />

generation offer to the next level by<br />

extending the range while developing<br />

new technologies to achieve net<br />

zero value-chain emissions.”<br />

16<br />

17

POWER GENERATION<br />

#BAUDOUIN #MEEDUBAI<br />

POWER GENERATION<br />

#PERKINS #5000 #MEEDUBAI<br />

BAUDOUIN<br />

PERKINS 5000 SERIES<br />

MULTIPLE<br />

CHOICE<br />

“By diversifying our portfolio, we’re<br />

able to provide our customers with<br />

more choices and greater flexibility,<br />

allowing them to choose the engine<br />

solution that best meets their needs”<br />

WHAT<br />

GREAT<br />

A<br />

t MEE 2022 we will be unveiling<br />

some new products and a<br />

new partnership with PSI.”<br />

This is what Baudouin’s management<br />

told us in their latest interview<br />

with POWERTRAIN <strong>International</strong>.<br />

Because the French company<br />

of the Weichai Group chose Dubai as<br />

the elective scenario for its establishment<br />

in power generation. Given that<br />

Baudouin is the Platinum Sponsor of<br />

this edition, at MEE <strong>2023</strong> they unveiled<br />

the 8M33, the latest in the proven<br />

M33 range, one of the top selling<br />

engines platforms for High Horse Power.<br />

With a power range of 800-1125<br />

kVA, its V8 design offers a leading<br />

compact, power-dense engine with a<br />

high-pressure common rail injection<br />

system. It offers a two-year warranty<br />

and unlimited hours for prime power<br />

applications, and 4 years and 800<br />

hours for emergency standby power<br />

applications. There are of course also<br />

data centers in Baudouin’s thoughts.<br />

For these critical applications, so crucial<br />

in industrial and social balances,<br />

there is the 16M55 PowerKit. This engine<br />

offers a power range from 3313-<br />

3750 kVA at 50 Hz, providing highly<br />

competitive power density for Emergency<br />

Standby Applications. With<br />

low fuel consumption and extended<br />

mean time between overhauls. About<br />

PowerKit Lean Burn Gas engines,<br />

we saw the 6M16, which is available<br />

in 163-188 kVA. This electronically<br />

controlled engine offers high transient<br />

and block load capabilities, with the<br />

ability to ramp up to 50% in a single<br />

Baudouin was Platinum<br />

Sponsor of MEE <strong>2023</strong>,<br />

where it presented<br />

the 8M33, 16M55, PSI<br />

8.8LTCAC and the<br />

Weichai ESS Battery<br />

step. It can run on low methane numbers<br />

and its lean burn technology results<br />

in lower NOx emissions. The engine<br />

can also run on biogas fuel for a<br />

more sustainable and efficient energy<br />

solution. It has full-duty cycle capability,<br />

from prime to continuous power,<br />

backed by Baudouin’s best-in-class<br />

warranty of two years and unlimited<br />

hours for prime power applications<br />

and one year with unlimited hours for<br />

continuous power applications. The<br />

8.8LTCAC engine from PSI can generate<br />

up to 179 kWe and is available<br />

in 50Hz and 60Hz.<br />

Finally, we mention Weichai ESS<br />

Battery, a high-performance energy<br />

storage system from Weichai Power.<br />

The Weichai ESS Battery is built<br />

using Lithium-ion battery technology<br />

supporting a maximum of 1500 VDC<br />

with low loss at the AC side, which<br />

offers high energy density, long cycle<br />

life up to 15 years, and fast charging<br />

capabilities.<br />

W<br />

e gave you some previews<br />

in the July 2022 issue.<br />

Now, the 5000 Series is<br />

ready to show itself to the<br />

public. It took place at MEE, where<br />

Perkins displayed the full authority<br />

electronic range of in-line six and<br />

eight cylinder and V12 and V16 cylinder<br />

engines. Again, as in the Volvo<br />

Penta case just described, Perkins<br />

has raised the bar for the top of the<br />

range. “With over 90 years of design<br />

experience, Perkins understands<br />

that better electric power performance<br />

means maximising the design<br />

and effectiveness of every part, design,<br />

and service that goes into each<br />

solution, including all new 5000 Series,”<br />

said Jaz Gill, Vice President<br />

of Perkins global sales marketing,<br />

service and parts. “The new range<br />

has been designed to optimise our<br />

customers’ needs for quick, reliable<br />

and cost-effective power, and for applications<br />

where real estate is at a<br />

EPIPHANY<br />

Jaz Gill: “The new range<br />

has been designed to<br />

optimise our customers’<br />

needs for quick, reliable<br />

and cost effective power,<br />

and for applications<br />

where real estate is<br />

at a premium”<br />

premium, such as in a hospital, the<br />

high power density of the 5000 Series<br />

provides a compact design that<br />

packs power into a small, compact<br />

footprint.” Packed with features and<br />

the performance to provide dependable<br />

power output up to 2500 kVA<br />

for standby and 2250 kVA for prime<br />

applications, the 5000 Series is designed<br />

to supply electrical power<br />

when and where needed. Optimised<br />

turbochargers enable the 5000 Series<br />

engines to deliver outstanding<br />

load acceptance meeting ISO 8528 5<br />

G2 and G3 standards and the ability<br />

to accept 100 percent block load<br />

to NFPA standards. Designed, engi-<br />

The Perkins 5000<br />

Series is on the launch<br />

pad. The confirmation<br />

during the Emirates<br />

event<br />

neered and built to provide dependable<br />

power for prime and standby<br />

installations including data centres<br />

and hospitals, the 5000 Series has<br />

been rigorously tested for performance<br />

and durability with more than<br />

10,000 running hours already under<br />

its belt. With critical infrastructure<br />

at stake, the engine has been tested<br />

and proven in harsh environments.<br />

For generator manufacturers and<br />

end users looking to reduce their<br />

carbon emissions, the 5000 Series<br />

can, subject to meeting Perkins’<br />

run with biodiesel up to B20 based<br />

on a 20% dilution of biodiesel with<br />

standard diesel or on 100% HVO.<br />

The 5000 Series engines decrease<br />

fluid consumption and extend service<br />

intervals with redesigned parts<br />

including new piston rings and liner<br />

assembly, electronic fuel system and<br />

fuel filters to deliver a long-life span<br />

and improved efficiency to minimise<br />

the total cost of operation.<br />

18<br />

19

EVENTS<br />

#ISOTTAFRASCHNI #FINCANTIERI #INNOVATION<br />

ISOTTA FRASCHINI CIS<br />

CENTRE<br />

OF<br />

EXPERTISE<br />

The CIS, Innovation and Development<br />

Center, was inaugurated on<br />

March 1 st at the Isotta Fraschini<br />

Motori headquarters in Bari. It<br />

will deal with the study of new power<br />

management systems, considering also<br />

renewable energies, including fuel cells,<br />

and the design of a new engine platform<br />

that meets the need to reduce emissions,<br />

with the ultimate goal of using hydrogen.<br />

The first speaker to take the stage is<br />

Michele Emiliano, President of the<br />

Puglia Region: “Isotta Fraschini has<br />

been able to keep alive a story that today<br />

affects future generations, through the<br />

CIS. Thanks to the initiative of Fincantieri,<br />

a company that represents Italy and<br />

its human capital, and to the vision it is<br />

realizing, I think Puglia today is the right<br />

place at the right time to build a future<br />

whose today’s initiative is only one of<br />

Among the activities<br />

of the CIS, new power<br />

management systems,<br />

study of renewables,<br />

testing of fuel cells and<br />

alternative fuels (HVO,<br />

methanol, ammonia),<br />

a new engine platform.<br />

“For Fincantieri, Isotta<br />

Fraschini has been<br />

part of the group’s<br />

energy transition<br />

strategy,” Pierroberto<br />

Folgiero, General<br />

Manager of Fincantieri<br />

Group<br />

the first steps.” It is Giuseppe Joe Gelonese,<br />

marketing and communication<br />

manager at Isotta Fraschini, who does<br />

the honors: “It is a real privilege for me<br />

to be able to present today a new page<br />

in the history of this company, a new<br />

chapter that looks towards a challenging<br />

future for Isotta Fraschini Motori.”<br />

He gives the floor to the president Sergio<br />

Razeto, who, after greeting the audience,<br />

announces: “The Innovation and<br />

Development Center that we are going<br />

to inaugurate is a significant part of our<br />

journey. We started five years ago, beginning<br />

to work on three different lines:<br />

safety and compliance with regulations,<br />

review of products and systems, review<br />

of supplier organization processes.”<br />

More than 5 million Euros have been invested<br />

to improve the structure and, as<br />

regards the products, important changes<br />

Giovanni Bruni, chief operating officer<br />

at IFM, introduces us to the heart of the<br />

IFuture project, which we started talking<br />

about on POWERTRAIN in July<br />

2020: “We believe that a program that<br />

evokes the future even in its name must<br />

be described and presented by those who<br />

today represent the future of Isotta Fraschini,<br />

that is by our young colleagues.”<br />

Federica Gazzilli, engineer and Planning<br />

& Management Specialist, responses<br />

to the invitation, illustrating the program<br />

and the creation of new products,<br />

in line with the expectations of environmental<br />

sustainability. “The first goal we<br />

achieved was to obtain a new type of<br />

product deriving it from the mature and<br />

proven experience in the marine field,<br />

with characteristics such as constructive<br />

simplicity, which has allowed us, among<br />

other things, to obtain a significant rehave<br />

been made, while the service has<br />

been completely reorganised. “Even the<br />

offshore patrol vessels from the fourth<br />

unit”, adds Razeto, “are fitted with the<br />

Isotta engine developed in collaboration<br />

with the Italian Navy after having run<br />

3,000 hours in the test room. The organization<br />

has changed, the top positions<br />

have been revised, logistics has been<br />

created with the integration of a modern<br />

automatic warehouse and a traceability<br />

system.” The collaboration with the<br />

Polytechnic University of Bari also continues.<br />

Isotta Fraschini Motori currently<br />

has three PhDs in progress, but above all<br />

the operation designed to restore value<br />

to the brand continues. It is called “Back<br />

to the basic” and aims to create a lower<br />

cost product that can also be used for the<br />

terrestrial sector. “Today we have a 16<br />

and a 12-cylinder, modern engines with<br />

a well-tested heart made with a 40% cost<br />

reduction without sacrificing reliability<br />

and quality. In collaboration with the<br />

Navy and our military division, we are<br />

building a new engine that will represent<br />

our future. The prototype will be ready<br />

by the end of the year after undergoing a<br />

long and demanding validation process.<br />

For this project, the Puglia Region has<br />

requested us to hire 32 people and, being<br />

aware that we would not have had<br />

a significant workload without the introduction<br />

of new products, we have hired<br />

24 engineers and 8 technicians, creating<br />

our own Innovation and Development<br />

Centre.” Among the activities included<br />

in the CIS program, the transition towards<br />

the production of “green” energy<br />

has a prominent position, with the study<br />

of new fuels (including hydrogen) and<br />

the design and construction of fuel cells.<br />

20<br />

21

INTERVIEW<br />

#ISOTTAFRASCHNI #FINCANTIERI #INNOVATION<br />

The new Isotta Fraschini Innovation and Development<br />

Center has been strongly desired and integrated into<br />

the Fincantieri business plan<br />

duction in costs.” Gazzilli then illustrates<br />

the ongoing research activities in collaboration<br />

with the CNR and the STEM of<br />

Naples, aimed at the use of alternative<br />

fuels (in particular HVO, methanol and<br />

ammonia) on the single-cylinder engine,<br />

which will subsequently be tested<br />

on real engines. The design of the<br />

new engine family will then follow. It<br />

will have to meet future needs in terms<br />

of performance, power, emissions and<br />

environmental sustainability, thanks<br />

to a modular architecture of different<br />

displacements, from 8 to 20 cylinders,<br />

capable of delivering up to 5,000 kW<br />

in propulsion configuration and 4,000<br />

kW in power generation configuration.<br />

The key feature of this engine is that it<br />

will be powered by alternative fuels and<br />

capable of running on 100% hydrogen.<br />

“We are also involved in important projects<br />

for the development of fuel cell systems<br />

intended for marine applications<br />

thanks to some activities carried out together<br />

with Fincantieri, such as the fuel<br />

cell test of 30-kilowatt Proton Motor<br />

systems, the verification of fuel cell systems<br />

with batteries on the ship Zeus and<br />

testing of a 5-kW prototype unit powered<br />

by hydrogen-oxygen with the Tecbia<br />

project. These activities have allowed<br />

IFM to develop a complete modular<br />

system with 500 kilowatt modules, even<br />

of smaller sizes. The last – no less important<br />

– point of the IFuture program<br />

is the development of a monitoring and<br />

management system for Isotta Fraschini<br />

products, capable of collecting data and<br />

analyzing it even remotely, thus facilitating<br />

predictive maintenance.”<br />

Now it is the turn of the managing director<br />

and general manager of Fincantieri,<br />

Pierroberto Folgiero, to have his say:<br />

“The work that has been done in the past<br />

is commendable. Skills met skills, and<br />

it wasn’t a casual encounter. We need<br />

to focus on concreteness, set ourselves<br />

short, medium and long-term goals.<br />

For Fincantieri, Isotta Fraschini has<br />

been part of the group’s energy transition<br />

strategy, within the industrial plan,<br />

as well as in the Italian Navy’s service<br />

strategy. All the efforts that have been<br />

made to raise quality are the basis for<br />

our future, and for this we have to thank<br />

the company’s production capacity. In<br />

the future there will be more work to be<br />

done to turn the product “into reality”,<br />

a major project that is going ahead and<br />

which will allow the opening of further<br />

markets. It is clear that if we succeed in<br />

this, Isotta Fraschini will become the<br />

pole of expertise for everything related<br />

to the marinization of fuel cells. Clear<br />

ideas, clear goals, attention to quality,<br />

gratitude to those who have done all<br />

this and above all gratitude to the territory:<br />

the ingredients are all there.”<br />

The last speech is made by the managing<br />

director of Isotta Fraschini Motori,<br />

Marco Acca, who thanks all the guests<br />

on behalf of all the men and women in<br />

the company: “Your presence is important<br />

for us because it focuses attention<br />

on an industrial reality in which competent,<br />

motivated and aware people<br />

can contribute to the energy transition,<br />

strongly supported by the industrial<br />

plan recently launched by the Fincantieri<br />

group. ” At the ribbon cutting, done<br />

by Forgiero, we have the opportunity to<br />

ask the CEO of Fincantieri a question.<br />

How will the CIS dialogue with Fincantieri’s<br />

research and development? “We<br />

have created a new corporate management<br />

that has all the operating activities<br />

under the same hat: research and development,<br />

purchasing and innovation activities,<br />

precisely to try to intertwine well<br />

at group level and not overlap the work<br />

of many different companies.” Then,<br />

we explored the organizational aspects<br />

of the CIS with Gianluca Piscopo, the<br />

engineer responsible for the design and<br />

development of new engines. “With the<br />

creation of the CIS, we wanted to bring<br />

a bit of know-how about electronics and<br />

software ‘back into the house’, as it was<br />

previously supplied to us from outside.<br />

We have also presented an investment<br />

plan – now in the approval stage – precisely<br />

on corporate digitization, focused<br />

in particular on the remote monitoring<br />

system, developed in a very modular<br />

perspective according to customer<br />

needs. Today, at CIS, we have 7 people<br />

dedicated to electronics and software, 6<br />

to fuel cells, 15 to mechanical design of<br />

both orders and products, 8 to product<br />

development and study of alternative<br />

fuels. However, all the software that we<br />

are designing will go hand in hand with<br />

both the engine and the fuel cell. In our<br />

opinion, the internal combustion engine<br />

will still be the key to decarbonisation:<br />

while there are few fuel cell manufacturers,<br />

three or four in the world, as far<br />

as the engine is concerned, we have already<br />

trained workers and workshops<br />

that know how to provide assistance.”<br />

The next steps of this ambitious program<br />

will be the construction over the<br />

next two years of three test rooms: one<br />

for hydrogen, one for hybrid, where gas<br />

can also be tested, and a larger room for<br />

the new developing engine platform.<br />

22<br />

23

OFF-HIGHWAY<br />

#AGCOPOWER #CONEXPOAGG/CON #CAT #CUMMINS #DEUTZ #FPTINDUSTRIAL<br />

CONEXPO-AGG/CON<br />

PROUD<br />

TO BE<br />

NEUTRAL<br />

In Las Vegas,<br />

decarbonisation<br />

is played out in<br />

the best tradition<br />

of American<br />

pragmatism.<br />

There was room<br />

for electrification<br />

proposals,<br />

hydrogen and even<br />

presentations of new<br />

ICEs. We tried to<br />

“pack” ConExpo into<br />

a glance<br />

Like Bauma in Munich, ConExpo-CON/AGG<br />

– which was held<br />

in sync with the IFPE – is an<br />

event, indeed, “the event”, at least<br />

as far as North America is concerned,<br />

which sums up the essence of the past<br />

three years and anticipates the sentiment<br />

of the three years to come. What have we<br />

brought home from this edition, which<br />

was previously mutilated by the onset<br />

of the pandemic? Here you will find a<br />

generous report, interviews, and insights<br />

will be in future issues. We heard in unison<br />

“there is no winning technology in<br />

the short term”. Nothing new, but if this<br />

statement is reaffirmed by the drumbeat<br />

of the most energetic earthmoving market<br />

on the planet, its specific weight acquires<br />

density and authority, detaching<br />

itself from the calculated attentions of<br />

marketing. The three “technological environments”<br />

of the ICE - EV - H2 triad<br />

impose themselves almost equally. Cat<br />

and Perkins, Cummins, Deutz, Hyundai<br />

DI, Kubota, Rolls-Royce, Volvo Penta<br />

are some examples of triangulation<br />

between the technologies mentioned<br />

above, which can be found on the respective<br />

stands. Not to mention the contribution<br />

of some giants in the field of<br />

pneumo-electro-hydraulic components,<br />

such as Bosch Rexroth and Danfoss.<br />

Electrification, however, captured the<br />

attention of the auditorium, driven by<br />

the acceleration of the usual meticulous<br />

CARB (quoting the success of an eighties<br />

band from San Francisco, California<br />

über alles, which fits perfectly due to the<br />

rigor and regulatory foresight of the Californian<br />

institution). A trend not yet at the<br />

levels of Munich, but enough to impose<br />

itself on the agenda of systems analysts.<br />

The Inflation Reduction Act, which was<br />

strongly supported by the Biden administration,<br />

with an investment of 369<br />

billion dollars for “energy security and<br />

climate change”, strongly hints at hydrogen.<br />

Yet the mistreated ICE has not<br />

been abandoned, even in the conventional<br />

Diesel cycle approach. As evidence<br />

we mention the investments of Hyundai<br />

Doosan Infracore, which announces the<br />

launch in 2024 of a new 5 and 7.5-litre<br />

engine; Cummins, which has a 10-litre<br />

engine made specifically for the EPA;<br />

FPT Industrial, which handed over the<br />

keys to decarbonisation to the F28 hybrid,<br />

relying for the rest on the tried<br />

and tested team of compacts, NEF and<br />

Cursor. In Turin they showed off the full<br />

range, exhibiting some specimens, such<br />

as the F36, which had so far escaped the<br />

general public due to the curse of Covid.<br />

And what about the pleasant return of<br />

Deutz to trade fair events, testifying the<br />

wind of change blowing in the renewed<br />

Board of Directors in Cologne, with the<br />

consolidated masterpieces, which are<br />

moreover supported by the results of investments<br />

in “plug-in” charging centres<br />

and electrolysers. For some, this is the<br />

trump card to stem the impetuous Chinese<br />

hegemony in battery packs and,<br />

consequently, in the entire electrification<br />

infrastructure. And yet, thinking of<br />

new endothermic players, the surprise<br />

comes from the Peterborough-Peoria<br />

axis. Indeed, Caterpillar presented to<br />

the American audience a 13-litre engine,<br />

the offspring of a series conceived<br />

from scratch. A preview that interrupts<br />

the multi-year static nature of the yellow<br />

motoring family, conceived jointly<br />

with the Perkins “cousins”. Kubota also<br />

renews its faith in diesel, with additions<br />

that we will tell you about at length.<br />

Also in Las Vegas, as in Munich, the<br />

threshold of 56 kilowatts is a clear indication<br />

for OEMs: below this the battery<br />

pack weighs little, absorbs energy<br />

in an acceptable way and lends itself to<br />

meet the needs of the equipment, otherwise<br />

subject to hydraulic and pneumatic<br />

mechanisms.<br />

What about hydrogen? We told you<br />

about JCB, which relaunched the indirect-injection<br />

4.8 engine. This could<br />

be the trump card compared to the lucubrations<br />

of competitors, committed<br />

to adapting the common rail, such as<br />

Liebherr, or the putative parents of agnostic<br />

engines, such as Cummins and<br />

FPT Industrial, and Volvo Penta’s bifuel.<br />

We also found the name of the newborn<br />

Korean conglomerate Hyundai Doosan<br />

24<br />

25

OFF-HIGHWAY<br />

#JCB #JOHNDEERE #HONDA #ISUZU #HYUNDAIDOOSAN #KOHLER<br />

HONDA AUTONOMOUS WORK VEHICLE<br />

Honda is moving in the direction of electrification<br />

and automatization of construction machinery. This is<br />

exemplified by the prototype Honda Autonomous Work<br />

Vehicle (AWV). Increased bed size to two pallets and<br />

greater loading capacity of 2,000 pounds, AWV improved<br />

navigation in locations where GNSS (global navigation<br />

satellite system) service is<br />

weak or unavailable using<br />

LiDAR sensors. The speed<br />

in autonomous mode is<br />

up to 10 miles per hour.<br />

Battery size has improved<br />

and operating time is up to<br />

10 hours. The Honda AWV<br />

employs a suite of sensors to<br />

operate autonomously, using<br />

GPS for location, radar and<br />

LiDAR for obstacle detection<br />

and cameras for remote monitoring. Previous field tests<br />

have also successfully verified that multiple Honda AWVs<br />

can transport and deliver construction materials and<br />

supplies at precise points along a pre-set route.<br />

Phil Kelliher, Caterpillar senior vice president and ConExpo-CON/AGG<br />

show chair: “Live events in the construction industry are very important,<br />

because you can see, touch and experience the products”<br />

Infracore imprinted on an 11-liter hydrogen<br />

engine. Let’s start in order, with<br />

ICE. Finally, it was Caterpillar’s turn,<br />

with the C13D, unveiled in the presence<br />

of David Nicoll, Cat’s Vice President.<br />

“The commercial availability of these<br />

engines will be effective in 2026. Why<br />

did we develop this new engine? In the<br />

first place we thought of power density,<br />

at maximum rated power, increased by<br />

10% compared to the current single-turbine<br />

C18. What about the after-treatment?<br />

It is included in the CCTV package,<br />

and a complete industrial power<br />

unit including pre-assembled radiator,<br />

flywheel and alternator. This engine will<br />

find itself operating in harsh environments.<br />

Therefore, it has been designed<br />

to operate at 12,000 feet (3,658 meters,<br />

Ed.), twice the current 13-liter engine,<br />

and at temperatures of 140 Fahrenheit<br />

degrees (60 Celsius degrees, Ed.), up to<br />

minus 40. Like most Caterpillar engines,<br />

the C13D can use 100% HVO and B20<br />

biodiesel as a diesel replacement. The<br />

basic architecture can adapt to future<br />

fuel developments: hydrogen and natural<br />

gas. What about the noise? It has<br />

been reduced by 3 decibels. Finally, let’s<br />

talk about fuel consumption. The C13D<br />

consumes 10% less fuel and is the most<br />

efficient engine Caterpillar has ever developed.<br />

From a maintenance point of<br />

view, we have extended maintenance<br />

intervals to 1,000 hours”. We jump<br />

over the “fence” that separates the two<br />

stands, and we find ourselves at Perkins,<br />

which has the twin engine, signed<br />

2606J-E13TA. The name changes, not<br />

the cylinder displacement, the lowest<br />

common denominator of a 12.9-liter<br />

engine size, which increases the stroke<br />

by 5 millimeters (AxC 130x162). The<br />

apical power is 515 kW, between 1,800<br />

and 2,100 rpm, with 3,200 Nm at 1,300<br />

rpm. We have just presented the AGCO<br />

Power Core75, and it is already time<br />

for increased solutions. Compared to<br />

the ratings seen at bauma, the “American”<br />

7.5-liter engine delivers 250 kW<br />

at 1,850 rpm, maintaining the excellent<br />

torque performance: 1,450 Nm. The<br />

Core75 was joined by the 84 LXTN, a<br />

8.4-liter engine capable of 313 kW at<br />

1,850 rpm and 1,750 Nm at 1,500 rpm,<br />

approved to digest 100% HVO. In the<br />

first place, we appreciated the logo of<br />

Hyundai Doosan Infracore, which imprints<br />

the word Hyundai and confirms<br />

the conglomeration of the new Korean<br />

giant. In addition to the G2 compacts,<br />

we took note of two fanciful previews.<br />

The 4 and 6-cylinder modulare (AxC<br />

110x132) versions of the 1.25-liter cylinder<br />

displacement (5 and 7.5 liters respectively),<br />

in production starting next<br />

year, were visible under the case. Vegas<br />

was also an opportunity to recover the<br />

traces of Isuzu, whose presence in North<br />

America is strong and deeply rooted.<br />

Certified Tier 4 F/Stage V, there were<br />

the 4LE2, 2.2 litres, the 4JJ1, 3 litres, the<br />

4HK1, 5.2 litres, and the hexacylinder, 6<br />

HK1 with 7.8 liters and 6UZ1 with 9.8<br />

liters. Again, in Japan, this time in the<br />

company of Kubota. HVO compatible,<br />

D902-K and D1105-K, both equipped<br />

with TVCR system, 3-cylinder, remove<br />

fumes, reduce carbon emissions and<br />

meet regional emission standards EPA<br />

Tier 4, Stage V and China IV. Launch<br />

pad for the 3.9-litre engine by John<br />

Deere Power Systems, which we also<br />

found at the Deutz stand, which the<br />

Deere offers with a power segmentation<br />

up to 120 kilowatts. At the <strong>International</strong><br />

Trucks stand we saw the S13, 12.7<br />

size with 6 cylinders (AxC 130x160),<br />

1,800 bar common rail, fixed turbine,<br />

nine-blade fan (a couple less than previous<br />

versions), without EGR and with<br />

two-stage ATS. The kW are 378.7, the<br />

Nm 2,372.7, available already at 900<br />

rpm. Let’s turn the page and plug it in.<br />

Diego Rotti, Product Portfolio and Marketing<br />

Manager Off-road, explained<br />

that at ConExpo FPT Industrial sets<br />

the focus on the North American network,<br />

to emphasise the depth of the<br />

range. “We brought the compacts (F28<br />

and F36), NEF and Cursor, and the engines<br />

are available in IPU versions, fully<br />

equipped, which make installation work<br />

easier.” FPT powers several construction<br />

and industrial applications in North<br />

America, including Case, Tigercat and<br />

Komatsu backhoe loaders.<br />

Compared to Bauma, the emergence of<br />

electrical prospects was less vehement,<br />

yes, but enough to command attention.<br />

Cat and Perkins showed off the powertrain<br />

for diesel electric, integrated end-toend<br />

hybrid applications. The solution can<br />

be configured for an articulated off-highway<br />

landscape, with the described configuration<br />

plastically adapting to the<br />

applications of backhoes or telescopic<br />

handlers, consisting of a 48-volt scalable<br />

battery module, powershift transmission,<br />

20 kW motor-generator unit, inverter,<br />

and an advanced energy control module.<br />

To complete the system, we find<br />

the batteries announced and exhibited in<br />

Munich, 48, 300 and 600 Volts. 48 Volts<br />

solution also for Hyundai DI, with motor<br />

and inverter, 35 kW Lithium-ion bat-<br />

26<br />

27

OFF-HIGHWAY<br />

#KUBOTA #LIEBHERR #PERKINS #ROLLSROYCE #VOLVOPENTA<br />

Marcia Klein, Treasurer of Casappa Corp., and show chair of IFPE: “The success<br />

of ConExpo-CON/AGG and IFPE <strong>2023</strong> is a testament to the resilience and<br />

strength of the construction and fluid power industries, which have continued<br />

to adapt and innovate despite the challenges of the past three years”<br />

teries, an autonomy of two hours at an<br />

average load, and the possibility of plugin<br />

recharging. It was Cummins who put<br />

the gear on, pushing ahead, and filed the<br />

Accelera trademark. Eric Neal, executive<br />

director of Cummins’ Off-Highway<br />

business, said, “We are leading the energy<br />

transition by providing our customers<br />

with the right technology and leveraging<br />

our deep knowledge of their needs and<br />

applications.” With the Accelera logo,<br />

we saw the latest product in the battery<br />

portfolio, the NMC BP95E, a modular<br />

architecture that promises long life and<br />

fast recharging times, designed for compact<br />

machines, especially those working<br />