The Garage 354

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

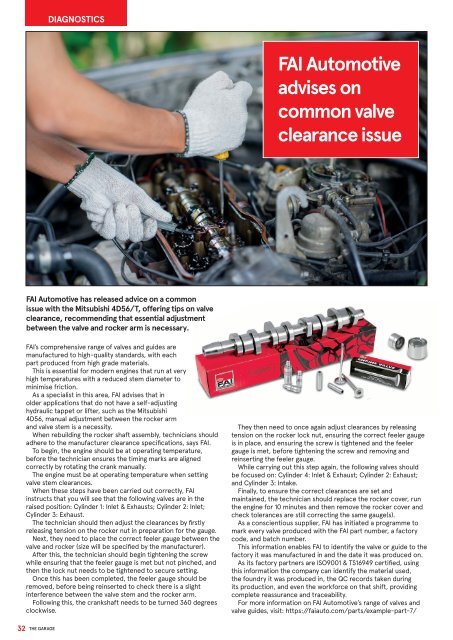

DIAGNOSTICS<br />

FAI Automotive<br />

advises on<br />

common valve<br />

clearance issue<br />

FAI Automotive has released advice on a common<br />

issue with the Mitsubishi 4D56/T, offering tips on valve<br />

clearance, recommending that essential adjustment<br />

between the valve and rocker arm is necessary.<br />

FAI’s comprehensive range of valves and guides are<br />

manufactured to high-quality standards, with each<br />

part produced from high grade materials.<br />

This is essential for modern engines that run at very<br />

high temperatures with a reduced stem diameter to<br />

minimise friction.<br />

As a specialist in this area, FAI advises that in<br />

older applications that do not have a self-adjusting<br />

hydraulic tappet or lifter, such as the Mitsubishi<br />

4D56, manual adjustment between the rocker arm<br />

and valve stem is a necessity.<br />

When rebuilding the rocker shaft assembly, technicians should<br />

adhere to the manufacturer clearance specifications, says FAI.<br />

To begin, the engine should be at operating temperature,<br />

before the technician ensures the timing marks are aligned<br />

correctly by rotating the crank manually.<br />

<strong>The</strong> engine must be at operating temperature when setting<br />

valve stem clearances.<br />

When these steps have been carried out correctly, FAI<br />

instructs that you will see that the following valves are in the<br />

raised position: Cylinder 1: Inlet & Exhausts; Cylinder 2: Inlet;<br />

Cylinder 3: Exhaust.<br />

<strong>The</strong> technician should then adjust the clearances by firstly<br />

releasing tension on the rocker nut in preparation for the gauge.<br />

Next, they need to place the correct feeler gauge between the<br />

valve and rocker (size will be specified by the manufacturer).<br />

After this, the technician should begin tightening the screw<br />

while ensuring that the feeler gauge is met but not pinched, and<br />

then the lock nut needs to be tightened to secure setting.<br />

Once this has been completed, the feeler gauge should be<br />

removed, before being reinserted to check there is a slight<br />

interference between the valve stem and the rocker arm.<br />

Following this, the crankshaft needs to be turned 360 degrees<br />

clockwise.<br />

<strong>The</strong>y then need to once again adjust clearances by releasing<br />

tension on the rocker lock nut, ensuring the correct feeler gauge<br />

is in place, and ensuring the screw is tightened and the feeler<br />

gauge is met, before tightening the screw and removing and<br />

reinserting the feeler gauge.<br />

While carrying out this step again, the following valves should<br />

be focused on: Cylinder 4: Inlet & Exhaust; Cylinder 2: Exhaust;<br />

and Cylinder 3: Intake.<br />

Finally, to ensure the correct clearances are set and<br />

maintained, the technician should replace the rocker cover, run<br />

the engine for 10 minutes and then remove the rocker cover and<br />

check tolerances are still correcting the same gauge(s).<br />

As a conscientious supplier, FAI has initiated a programme to<br />

mark every valve produced with the FAI part number, a factory<br />

code, and batch number.<br />

This information enables FAI to identify the valve or guide to the<br />

factory it was manufactured in and the date it was produced on.<br />

As its factory partners are ISO9001 & TS16949 certified, using<br />

this information the company can identify the material used,<br />

the foundry it was produced in, the QC records taken during<br />

its production, and even the workforce on that shift, providing<br />

complete reassurance and traceability.<br />

For more information on FAI Automotive’s range of valves and<br />

valve guides, visit: https://faiauto.com/parts/example-part-7/<br />

1<br />

32 THE GARAGE<br />

28-32 Feature Diagnostics.indd 4 30/08/2023 15:23