Issue 05/2023

Highlights Fibres / Textiles Polyurethane / Elastomers

Highlights

Fibres / Textiles

Polyurethane / Elastomers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fibres<br />

FDY production was possible at a pilot scale with up<br />

to 37 dtex and 24 filaments in the yarn, which results in<br />

1,54 dtex/filament. The production was merely limited<br />

by the current machine parameters, and the polymer<br />

can most likely withstand even higher stresses while<br />

spinning it, resulting in even finer yarns that are suitable<br />

for technical applications.<br />

COMPEO<br />

Leading compounding technology<br />

for heat- and shear-sensitive plastics<br />

To further validate the usability of the spun yarns for<br />

textile applications, the yarns were processed on different<br />

knitting machines. In the knitting trials, the unwinding<br />

properties and the general loop formation were comparable<br />

with industrial yarns.<br />

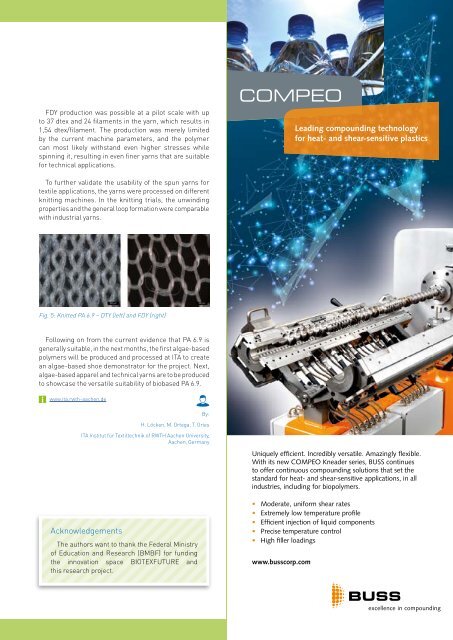

Fig. 5: Knitted PA 6.9 – DTY (left) and FDY (right)<br />

Following on from the current evidence that PA 6.9 is<br />

generally suitable, in the next months, the first algae-based<br />

polymers will be produced and processed at ITA to create<br />

an algae-based shoe demonstrator for the project. Next,<br />

algae-based apparel and technical yarns are to be produced<br />

to showcase the versatile suitability of biobased PA 6.9.<br />

www.ita.rwth-aachen.de<br />

By:<br />

H. Löcken, M. Ortega, T. Gries<br />

ITA Institut für Textiltechnik of RWTH Aachen University,<br />

Aachen, Germany<br />

Uniquely efficient. Incredibly versatile. Amazingly flexible.<br />

With its new COMPEO Kneader series, BUSS continues<br />

to offer continuous compounding solutions that set the<br />

standard for heat- and shear-sensitive applications, in all<br />

industries, including for biopolymers.<br />

Acknowledgements<br />

The authors want to thank the Federal Ministry<br />

of Education and Research (BMBF) for funding<br />

the innovation space BIOTEXFUTURE and<br />

this research project.<br />

• Moderate, uniform shear rates<br />

• Extremely low temperature profile<br />

• Efficient injection of liquid components<br />

• Precise temperature control<br />

• High filler loadings<br />

www.busscorp.com<br />

bioplastics MAGAZINE | Renewable Carbon Plastics [<strong>05</strong>/23] Vol. 18<br />

23