Issue 05/2023

Highlights Fibres / Textiles Polyurethane / Elastomers

Highlights

Fibres / Textiles

Polyurethane / Elastomers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cellulose nano fibres –<br />

a smooth additive<br />

The next big event, the FAKUMA (Friedrichshafen,<br />

Germany) is just around the corner and Asahi Kasei<br />

(Tokyo, Japan) will present, among other things, their<br />

cellulose nano fibre (CNF). Renewable Carbon Plastics talked<br />

to Tomofumi Maekawa, General Manager XRP Development<br />

Project at Asahi Kasei’s Sustainable Polymers Laboratory,<br />

about the material. “The material is derived from cotton linter,<br />

a by-product of the cotton yield, which is usually considered<br />

as a waste material. We only use cotton linter which is already<br />

GRS-certified or in the process of acquiring the certification”,<br />

said Maekawa. “CNF is generated from fibrillated pulp.<br />

Going down to the nanoscopic scale makes our fibre boast<br />

high strength and elasticity, in addition to its lightweight”.<br />

One field of application is to replace glass fibre, as the<br />

material shows a reinforcing effect when used in small<br />

amounts while being lighter than glass fibre. “Naturally,<br />

we aim for glass fibre replacement in plastic compounds.<br />

Since our CNF is a very soft material, it is suitable for sliding<br />

part applications as a filler that does not damage the mating<br />

material. It also shows less material degradation in the<br />

recycling process than glass fibres, which is another added<br />

value”, comments Maekawa. “There is a broad range of<br />

possible applications. One is, for example, in gears and other<br />

moving parts, which can benefit from CNF’s outstanding<br />

sliding properties. Due to its thixotropic behaviour, it also<br />

features a unique viscosity, making it suitable for 3D printing<br />

applications. Compared to other additives, CNF contributes<br />

to a smoother surface appearance after the printing process”.<br />

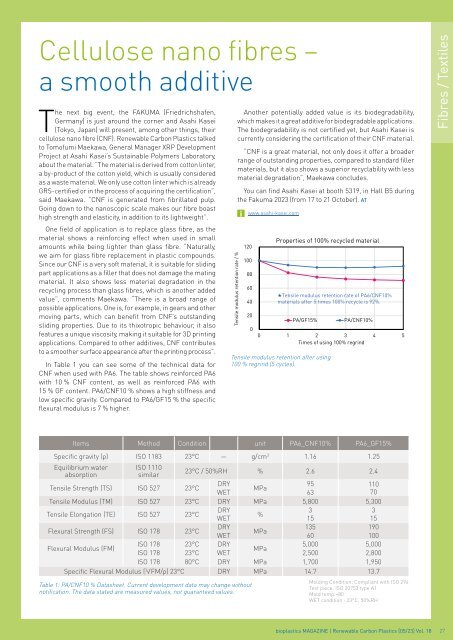

In Table 1 you can see some of the technical data for<br />

CNF when used with PA6. The table shows reinforced PA6<br />

with 10 % CNF content, as well as reinforced PA6 with<br />

15 % GF content. PA6/CNF10 % shows a high stiffness and<br />

low specific gravity. Compared to PA6/GF15 % the specific<br />

flexural modulus is 7 % higher.<br />

Tensile modulus retention rate / %<br />

Another potentially added value is its biodegradability,<br />

which makes it a great additive for biodegradable applications.<br />

The biodegradability is not certified yet, but Asahi Kasei is<br />

currently considering the certification of their CNF material.<br />

“CNF is a great material, not only does it offer a broader<br />

range of outstanding properties, compared to standard filler<br />

materials, but it also shows a superior recyclability with less<br />

material degradation”, Maekawa concludes.<br />

You can find Asahi Kasei at booth 5319, in Hall B5 during<br />

the Fakuma <strong>2023</strong> (from 17 to 21 October). AT<br />

120<br />

100<br />

www.asahi-kasei.com<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Properties of 100% recycled material<br />

★Tensile modulus retention rate of PA6/CNF10%<br />

materials after 5 times 100% recycle is 92%.<br />

PA/GF15%<br />

Tensile modulus retention after using<br />

100 % regrind (5 cycles).<br />

PA/CNF10%<br />

0 1 2 3 4 5<br />

Times of using 100% regrind<br />

Fibres / Textiles<br />

Items Method Condition unit PA6_CNF10% PA6_GF15%<br />

Specific gravity (ρ) ISO 1183 23°C ― g/cm 3 1.16 1.25<br />

Equilibrium water<br />

absorption<br />

ISO 1110<br />

similar<br />

Table 1: PA/CNF10 % Datasheet. Current development data may change without<br />

notification. The data stated are measured values, not guaranteed values.<br />

23°C / 50%RH % 2.6 2.4<br />

Tensile Strength (TS) ISO 527 23°C<br />

DRY<br />

95 110<br />

MPa<br />

WET 63<br />

70<br />

Tensile Modulus (TM) ISO 527 23°C DRY MPa 5,800 5,300<br />

Tensile Elongation (TE) ISO 527 23°C<br />

DRY<br />

3 3<br />

%<br />

WET 15 15<br />

Flexural Strength (FS) ISO 178 23°C<br />

DRY<br />

135 190<br />

MPa<br />

WET 60 100<br />

Flexural Modulus (FM)<br />

ISO 178 23°C DRY<br />

5,000 5,000<br />

MPa<br />

ISO 178 23°C WET 2,500 2,800<br />

ISO 178 80°C DRY MPa 1,700 1,950<br />

Specific Flexural Modulus ( 3 √FM/ρ) 23°C DRY MPa 14.7 13.7<br />

Molding Condition: Compliant with ISO 294<br />

Test piece: ISO 20753 type A1<br />

Mold temp.=80<br />

WET condition : 23°C, 50%RH<br />

bioplastics MAGAZINE | Renewable Carbon Plastics [<strong>05</strong>/23] Vol. 18<br />

27