drinkworld Technology + Marketing 1/2024

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

drinkworld Technology + Marketing is the leading magazine for the entire drinks industry worldwide. Feature articles and short communications cover the whole spectrum of processing, bottling, raw materials, logistics, packaging and marketing of beverages. We also report on special topics of regional interest and the trends in the beverage industries worldwide. Readers are executives and decision-makers in the brewing, dairy and mineral water industries, manufacturers of non-alcoholic drinks, wine growers and bottlers.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cover Story<br />

well-prepared, meaningful insights. In<br />

practice, breweries are familiar with the<br />

periodic reports on sustainability KPIs:<br />

They are again wallpaper of numbers,<br />

laboriously compiled, almost impossible<br />

to interpret, and not suitable for timely<br />

intervention. An inefficiency the real<br />

product would have to remedy: It<br />

should measure, condense the data into<br />

meaningful information and interpret it,<br />

help with optimization, and convert the<br />

information into recommendations for<br />

action, such as modernization, etc.<br />

Sustainability is not an island<br />

Dr. Hassan Yazdi, an expert in customercentric<br />

digital product development<br />

at GEA, highlighted the complexity of<br />

sustainability, noting, “Sustainability<br />

remains a buzzword if we consider it as<br />

a single goal. We can't come up with a<br />

meaningful product at this buzzword<br />

level.” The initial single-solution<br />

approach evolved after the initial<br />

meeting, acknowledging the intertwined<br />

nature of brewery operations. Yazdi<br />

remarked, “The plant is a mix of<br />

everything,” stressing that interventions<br />

impact productivity and quality. He<br />

provocatively suggested that stopping<br />

production would be the peak of<br />

sustainability but clarified that the true<br />

aim is to pursue defensible, responsible<br />

solutions within the brewing process.<br />

The language of production<br />

managers<br />

What are we talking about? Ticked<br />

off. And who are we talking to? The<br />

target audience for this innovation<br />

also shifted during the design process:<br />

It's no longer just sustainability<br />

managers, but production managers<br />

and operators in the field. It’s the<br />

middle management in breweries, the<br />

technical managers and production<br />

managers, that need comparable, clear<br />

and reliable data to make decisions<br />

about production processes. In many<br />

places they are still struggling with<br />

poorly aligned legacy systems, data<br />

from the PLC available only after the<br />

fact, and tons of paperwork. Being<br />

responsible for the entire production<br />

process means managing and<br />

considering a huge number of complex<br />

processes.<br />

Understanding processes: GEA<br />

InsightPartner<br />

While the aim of bolstering sustainability<br />

was clear, the solution paths quickly<br />

turned towards a digital tool offering<br />

AI-enabled real-time responsiveness<br />

and flexibility. Schneeberger and Yazdi<br />

didn’t have to start from scratch here,<br />

because in 2020/2021 they developed<br />

GEA InsightPartner process software<br />

in a similar way, which generates realtime<br />

information – i.e. knowledge – from<br />

real-time data. In a nutshell, events are<br />

tracked and correlated in their reallife<br />

environment. Plant managers get<br />

information that has been evaluated<br />

in a qualified manner and presented<br />

in intuitive dashboards. Now, GEA has<br />

added an intelligent system to the<br />

software to analyze data, conclude<br />

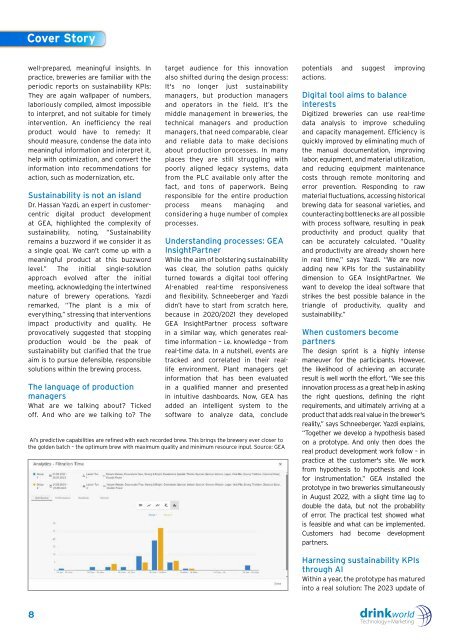

AI’s predictive capabilities are refined with each recorded brew. This brings the brewery ever closer to<br />

the golden batch – the optimum brew with maximum quality and minimum resource input. Source: GEA<br />

potentials and suggest improving<br />

actions.<br />

Digital tool aims to balance<br />

interests<br />

Digitized breweries can use real-time<br />

data analysis to improve scheduling<br />

and capacity management. Efficiency is<br />

quickly improved by eliminating much of<br />

the manual documentation, improving<br />

labor, equipment, and material utilization,<br />

and reducing equipment maintenance<br />

costs through remote monitoring and<br />

error prevention. Responding to raw<br />

material fluctuations, accessing historical<br />

brewing data for seasonal varieties, and<br />

counteracting bottlenecks are all possible<br />

with process software, resulting in peak<br />

productivity and product quality that<br />

can be accurately calculated. “Quality<br />

and productivity are already shown here<br />

in real time,” says Yazdi. “We are now<br />

adding new KPIs for the sustainability<br />

dimension to GEA InsightPartner. We<br />

want to develop the ideal software that<br />

strikes the best possible balance in the<br />

triangle of productivity, quality and<br />

sustainability.”<br />

When customers become<br />

partners<br />

The design sprint is a highly intense<br />

maneuver for the participants. However,<br />

the likelihood of achieving an accurate<br />

result is well worth the effort. “We see this<br />

innovation process as a great help in asking<br />

the right questions, defining the right<br />

requirements, and ultimately arriving at a<br />

product that adds real value in the brewer's<br />

reality,” says Schneeberger. Yazdi explains,<br />

“Together we develop a hypothesis based<br />

on a prototype. And only then does the<br />

real product development work follow – in<br />

practice at the customer's site. We work<br />

from hypothesis to hypothesis and look<br />

for instrumentation.” GEA installed the<br />

prototype in two breweries simultaneously<br />

in August 2022, with a slight time lag to<br />

double the data, but not the probability<br />

of error. The practical test showed what<br />

is feasible and what can be implemented.<br />

Customers had become development<br />

partners.<br />

Harnessing sustainability KPIs<br />

through AI<br />

Within a year, the prototype has matured<br />

into a real solution: The 2023 update of<br />

8