Operations Manual - Open Rails

Operations Manual - Open Rails

Operations Manual - Open Rails

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

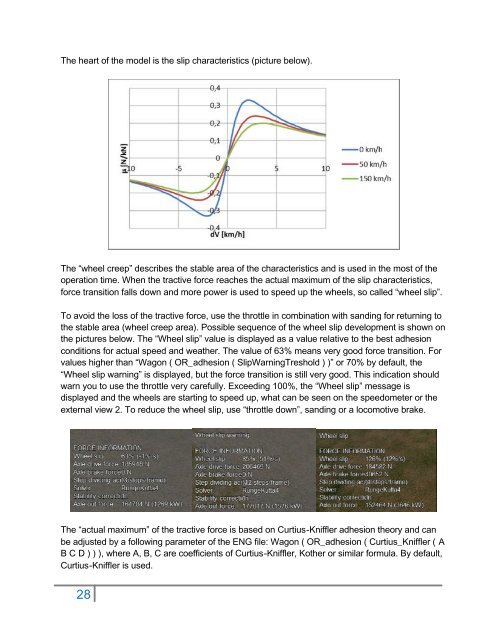

The heart of the model is the slip characteristics (picture below).<br />

The “wheel creep” describes the stable area of the characteristics and is used in the most of the<br />

operation time. When the tractive force reaches the actual maximum of the slip characteristics,<br />

force transition falls down and more power is used to speed up the wheels, so called “wheel slip”.<br />

To avoid the loss of the tractive force, use the throttle in combination with sanding for returning to<br />

the stable area (wheel creep area). Possible sequence of the wheel slip development is shown on<br />

the pictures below. The “Wheel slip” value is displayed as a value relative to the best adhesion<br />

conditions for actual speed and weather. The value of 63% means very good force transition. For<br />

values higher than “Wagon ( OR_adhesion ( SlipWarningTreshold ) )” or 70% by default, the<br />

“Wheel slip warning” is displayed, but the force transition is still very good. This indication should<br />

warn you to use the throttle very carefully. Exceeding 100%, the “Wheel slip” message is<br />

displayed and the wheels are starting to speed up, what can be seen on the speedometer or the<br />

external view 2. To reduce the wheel slip, use “throttle down”, sanding or a locomotive brake.<br />

The “actual maximum” of the tractive force is based on Curtius-Kniffler adhesion theory and can<br />

be adjusted by a following parameter of the ENG file: Wagon ( OR_adhesion ( Curtius_Kniffler ( A<br />

B C D ) ) ), where A, B, C are coefficients of Curtius-Kniffler, Kother or similar formula. By default,<br />

Curtius-Kniffler is used.<br />

28