10 years' success in the Middle Kingdom - Sick

10 years' success in the Middle Kingdom - Sick

10 years' success in the Middle Kingdom - Sick

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

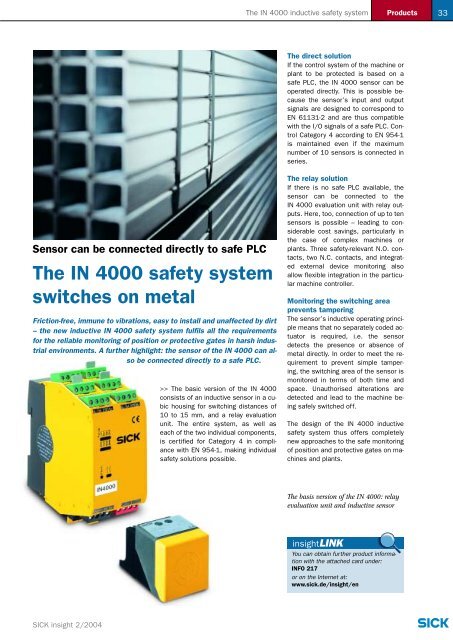

Sensor can be connected directly to safe PLC<br />

The IN 4000 safety system<br />

switches on metal<br />

Friction-free, immune to vibrations, easy to <strong>in</strong>stall and unaffected by dirt<br />

– <strong>the</strong> new <strong>in</strong>ductive IN 4000 safety system fulfils all <strong>the</strong> requirements<br />

for <strong>the</strong> reliable monitor<strong>in</strong>g of position or protective gates <strong>in</strong> harsh <strong>in</strong>dustrial<br />

environments. A fur<strong>the</strong>r highlight: <strong>the</strong> sensor of <strong>the</strong> IN 4000 can also<br />

be connected directly to a safe PLC.<br />

SICK <strong>in</strong>sight 2/2004<br />

>> The basic version of <strong>the</strong> IN 4000<br />

consists of an <strong>in</strong>ductive sensor <strong>in</strong> a cubic<br />

hous<strong>in</strong>g for switch<strong>in</strong>g distances of<br />

<strong>10</strong> to 15 mm, and a relay evaluation<br />

unit. The entire system, as well as<br />

each of <strong>the</strong> two <strong>in</strong>dividual components,<br />

is certified for Category 4 <strong>in</strong> compliance<br />

with EN 954-1, mak<strong>in</strong>g <strong>in</strong>dividual<br />

safety solutions possible.<br />

The IN 4000 <strong>in</strong>ductive safety system Products 33<br />

The direct solution<br />

If <strong>the</strong> control system of <strong>the</strong> mach<strong>in</strong>e or<br />

plant to be protected is based on a<br />

safe PLC, <strong>the</strong> IN 4000 sensor can be<br />

operated directly. This is possible because<br />

<strong>the</strong> sensor’s <strong>in</strong>put and output<br />

signals are designed to correspond to<br />

EN 61131-2 and are thus compatible<br />

with <strong>the</strong> I/O signals of a safe PLC. Control<br />

Category 4 accord<strong>in</strong>g to EN 954-1<br />

is ma<strong>in</strong>ta<strong>in</strong>ed even if <strong>the</strong> maximum<br />

number of <strong>10</strong> sensors is connected <strong>in</strong><br />

series.<br />

The relay solution<br />

If <strong>the</strong>re is no safe PLC available, <strong>the</strong><br />

sensor can be connected to <strong>the</strong><br />

IN 4000 evaluation unit with relay outputs.<br />

Here, too, connection of up to ten<br />

sensors is possible – lead<strong>in</strong>g to considerable<br />

cost sav<strong>in</strong>gs, particularly <strong>in</strong><br />

<strong>the</strong> case of complex mach<strong>in</strong>es or<br />

plants. Three safety-relevant N.O. contacts,<br />

two N.C. contacts, and <strong>in</strong>tegrated<br />

external device monitor<strong>in</strong>g also<br />

allow flexible <strong>in</strong>tegration <strong>in</strong> <strong>the</strong> particular<br />

mach<strong>in</strong>e controller.<br />

Monitor<strong>in</strong>g <strong>the</strong> switch<strong>in</strong>g area<br />

prevents tamper<strong>in</strong>g<br />

The sensor’s <strong>in</strong>ductive operat<strong>in</strong>g pr<strong>in</strong>ciple<br />

means that no separately coded actuator<br />

is required, i.e. <strong>the</strong> sensor<br />

detects <strong>the</strong> presence or absence of<br />

metal directly. In order to meet <strong>the</strong> requirement<br />

to prevent simple tamper<strong>in</strong>g,<br />

<strong>the</strong> switch<strong>in</strong>g area of <strong>the</strong> sensor is<br />

monitored <strong>in</strong> terms of both time and<br />

space. Unauthorised alterations are<br />

detected and lead to <strong>the</strong> mach<strong>in</strong>e be<strong>in</strong>g<br />

safely switched off.<br />

The design of <strong>the</strong> IN 4000 <strong>in</strong>ductive<br />

safety system thus offers completely<br />

new approaches to <strong>the</strong> safe monitor<strong>in</strong>g<br />

of position and protective gates on mach<strong>in</strong>es<br />

and plants.<br />

The basis version of <strong>the</strong> IN 4000: relay<br />

evaluation unit and <strong>in</strong>ductive sensor<br />

<strong>in</strong>sightLINK<br />

You can obta<strong>in</strong> fur<strong>the</strong>r product <strong>in</strong>formation<br />

with <strong>the</strong> attached card under:<br />

INFO 217<br />

or on <strong>the</strong> Internet at:<br />

www.sick.de/<strong>in</strong>sight/en