- Page 1 and 2:

Methods in Molecular BiologyTM Biol

- Page 3 and 4:

M E T H O D S I N M O L E C U L A R

- Page 5 and 6:

© 2002 Humana Press Inc. 999 River

- Page 8 and 9:

Preface Calcium plays an important

- Page 10 and 11:

Contents Dedication ...............

- Page 12:

Contents xi 26 Enzymatic Assays to

- Page 15 and 16:

xiv Contents of Companion Volume 15

- Page 17 and 18:

xvi Contributors LESLIE D. HICKS

- Page 19 and 20:

20 Dean, Kelsey, and Re

- Page 21 and 22:

2 Yazawa

- Page 23 and 24:

4 Yazawa Fig. 1. Schematic represen

- Page 25 and 26:

6 Yazawa Fig. 2. Shop drawing for t

- Page 27 and 28:

8 Yazawa DuPont-NEN and the molar c

- Page 29 and 30:

10 Yazawa Fig. 4. Examples of the C

- Page 31 and 32:

12 Yazawa 5. Plot the calculated Ca

- Page 33 and 34:

14 Yazawa 12. Starovasnik, M. A., D

- Page 35 and 36:

16 Fig. 1. Molecular structures and

- Page 37 and 38:

18 Linse 7. 0.1 M EDTA. Dissolve 37

- Page 39 and 40:

20 Linse iterate the other paramete

- Page 41 and 42:

22 Linse tive to small alterations

- Page 43 and 44:

24 Linse References 1. Tsien, R. Y.

- Page 45 and 46:

26 Haiech and Kilhoffer to use the

- Page 47 and 48:

28 Haiech and Kilhoffer where γ is

- Page 49 and 50:

30 Haiech and Kilhoffer reporter gr

- Page 51 and 52:

32 Haiech and Kilhoffer tein with i

- Page 53 and 54:

34 Haiech and Kilhoffer Calmodulin

- Page 55 and 56:

36 Haiech and Kilhoffer Fig. 3. Mec

- Page 57 and 58:

38 Haiech and Kilhoffer We may sugg

- Page 59 and 60:

40 Haiech and Kilhoffer 29. Stewart

- Page 61 and 62:

42 Haiech and Kilhoffer 62. Becking

- Page 63 and 64:

44 Martin and Bayley Fig. 1. Absorp

- Page 65 and 66:

46 Martin and Bayley evaporation. C

- Page 67 and 68:

48 Martin and Bayley 4. Set the tem

- Page 69 and 70:

50 Martin and Bayley Fig. 2. Near-U

- Page 71 and 72:

52 Martin and Bayley discussed by M

- Page 73 and 74:

54 Martin and Bayley References 1.

- Page 75 and 76:

20 Dean, Kelsey, and Reik

- Page 77 and 78:

58 Fabian and Vogel are equipped wi

- Page 79 and 80:

60 Fabian and Vogel The penetration

- Page 81 and 82:

62 Fabian and Vogel perature, ionic

- Page 83 and 84:

64 Fabian and Vogel Fig. 3. IR spec

- Page 85 and 86:

66 Fabian and Vogel Fig. 4. Lower t

- Page 87 and 88:

68 Fabian and Vogel These correlati

- Page 89 and 90:

70 Fabian and Vogel Fig. 5. Amide I

- Page 91 and 92:

72 Fabian and Vogel 4. ATR-FTIR spe

- Page 93 and 94:

74 Fabian and Vogel 25. Georg, H.,

- Page 95 and 96:

76 Weljie and Vogel Fig. 1. Simplif

- Page 97 and 98:

78 Weljie and Vogel Fig. 3. Steady-

- Page 99 and 100:

80 Weljie and Vogel VIS spectrophot

- Page 101 and 102:

82 Weljie and Vogel 4. A series of

- Page 103 and 104:

84 Table 1 Advanced Fluorescence Me

- Page 105 and 106:

86 Weljie and Vogel References 1. L

- Page 107 and 108:

20 Dean, Kelsey, and Reik

- Page 109 and 110:

90 Johnson and Tikunova is removed

- Page 111 and 112:

92 Johnson and Tikunova function of

- Page 113 and 114:

94 Johnson and Tikunova Fig. 2. Rat

- Page 115 and 116:

96 Johnson and Tikunova Fig. 3. Rat

- Page 117 and 118:

98 Johnson and Tikunova Fig. 4. Ca

- Page 119 and 120:

100 Johnson and Tikunova cence inte

- Page 121 and 122:

102 Johnson and Tikunova 6. Johnson

- Page 123 and 124:

104 Julenius Fig. 1. Under conditio

- Page 125 and 126:

106 Julenius 3. Mix 50 µL of NHS s

- Page 127 and 128:

108 Julenius Fig. 3. A typical sens

- Page 129 and 130:

110 Julenius (2), is used in the Ia

- Page 131 and 132:

20 Dean, Kelsey, and Reik

- Page 133 and 134:

114 Lopez and Makhatadze Fig. 1. Th

- Page 135 and 136:

116 Lopez and Makhatadze 6. Buffers

- Page 137 and 138:

118 Lopez and Makhatadze The excess

- Page 139 and 140:

20 Dean, Kelsey, and Reik

- Page 141 and 142:

122 Lopez and Makhatadze Fig. 1. Is

- Page 143 and 144:

124 Lopez and Makhatadze 2.5 mL are

- Page 145 and 146:

126 Lopez and Makhatadze pendence o

- Page 147 and 148: 128 Hicks et al. equipped with a pu

- Page 149 and 150: 130 Hicks et al. Fig. 2. Debye plot

- Page 151 and 152: 132 Hicks et al. and 1.0 mg/mL for

- Page 153 and 154: 134 Hicks et al. Fig. 3. Sedimentat

- Page 155 and 156: 136 Hicks et al. 5. Hayes, D. B. (M

- Page 157 and 158: 138 Trewhella and Krueger This chap

- Page 159 and 160: 140 Trewhella and Krueger of the sc

- Page 161 and 162: 142 Trewhella and Krueger Table 1 C

- Page 163 and 164: 144 Trewhella and Krueger beam, or

- Page 165 and 166: 146 Trewhella and Krueger At very l

- Page 167 and 168: 148 Trewhella and Krueger analytica

- Page 169 and 170: 150 Trewhella and Krueger collapsed

- Page 171 and 172: 152 Trewhella and Krueger P(r) func

- Page 173 and 174: 154 Trewhella and Krueger Fig. 3. S

- Page 175 and 176: 156 Trewhella and Krueger concentra

- Page 177 and 178: 158 Trewhella and Krueger by a Nati

- Page 179 and 180: 20 Dean, Kelsey, and Reik

- Page 181 and 182: 162 Doherty-Kirby and Lajoie metal

- Page 183 and 184: 164 Doherty-Kirby and Lajoie two Ca

- Page 185 and 186: 166 Doherty-Kirby and Lajoie 7. Pep

- Page 187 and 188: 168 Doherty-Kirby and Lajoie Fig. 1

- Page 189 and 190: 170 Doherty-Kirby and Lajoie Fig. 2

- Page 191 and 192: 172 Doherty-Kirby and Lajoie 5. Alt

- Page 193 and 194: 174 Doherty-Kirby and Lajoie phosph

- Page 195 and 196: 176 Shaw Fig. 1. Ribbon drawing of

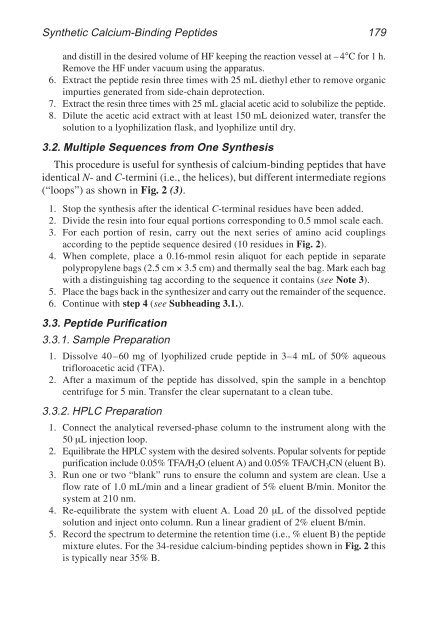

- Page 197: 178 Shaw 2.3. Other 1. Chemicals fo

- Page 201 and 202: 182 Shaw 10. Hodges, R. S., Semchuk

- Page 203 and 204: 184 Brokx and Vogel Table 1 An Over

- Page 205 and 206: 186 Brokx and Vogel Fig. 1. UV abso

- Page 207 and 208: 188 Brokx and Vogel Fig. 2. 20% SDS

- Page 209 and 210: 190 Brokx and Vogel it through an a

- Page 211 and 212: 192 Brokx and Vogel 8. Weljie, A. M

- Page 213 and 214: 20 Dean, Kelsey, and Reik

- Page 215 and 216: 196 Berliner Fig. 1. Aqueous X-band

- Page 217 and 218: 198 Berliner in the Bruker instrume

- Page 219 and 220: 200 Berliner Fig. 3. ESR spectra of

- Page 221 and 222: 202 Berliner Fig. 5. Low-temperatur

- Page 223 and 224: 204 Berliner 14. Musci, G., Reed, G

- Page 225 and 226: 206 Clarke and Vogel cal calcium-bi

- Page 227 and 228: 208 Clarke and Vogel Fig. 1. 113 Cd

- Page 229 and 230: 210 Clarke and Vogel Fig. 3. 113 Cd

- Page 231 and 232: 212 Clarke and Vogel Fig. 5. 113 Cd

- Page 233 and 234: 214 Clarke and Vogel The linewidth

- Page 235 and 236: 20 Dean, Kelsey, and Reik

- Page 237 and 238: 218 Drakenberg sands, of Hertz broa

- Page 239 and 240: 220 Drakenberg 1. Bloch equations m

- Page 241 and 242: 222 Drakenberg Fig. 2. Measurement

- Page 243 and 244: 224 Drakenberg Fig. 3. (A) 43 Ca NM

- Page 245 and 246: 226 Drakenberg Fig. 5. 43 Ca NMR sp

- Page 247 and 248: 228 Drakenberg NMR at sub-mM concen

- Page 249 and 250:

230 Drakenberg 30. Shimizu, T., Hat

- Page 251 and 252:

232 Weljie and Heringa Table 1 Amin

- Page 253 and 254:

234 Weljie and Heringa Table 2 Webs

- Page 255 and 256:

236 Weljie and Heringa diction meth

- Page 257 and 258:

238 Weljie and Heringa these databa

- Page 259 and 260:

240 Weljie and Heringa lineages. Th

- Page 261 and 262:

242 Weljie and Heringa compared, an

- Page 263 and 264:

244 Weljie and Heringa sequences as

- Page 265 and 266:

246 Weljie and Heringa much larger

- Page 267 and 268:

248 Weljie and Heringa ment require

- Page 269 and 270:

250 Weljie and Heringa 10. Kawasaki

- Page 271 and 272:

252 Weljie and Heringa 44. Thompson

- Page 273 and 274:

254 Weljie and Heringa

- Page 275 and 276:

256 Li et al. In order for these ex

- Page 277 and 278:

258 Li et al. 7. Mineral Mixture (s

- Page 279 and 280:

260 Li et al. 3. When the 45% D 2O/

- Page 281 and 282:

262 Li et al. sion system works eff

- Page 283 and 284:

264 Li et al. reliably produce high

- Page 285 and 286:

20 Dean, Kelsey, and Reik

- Page 287 and 288:

268 Mal et al. NMR data, X-PLOR (11

- Page 289 and 290:

270 Mal et al. Table 1 Simulated An

- Page 291 and 292:

272 Mal et al. 3.1.2.1. AMBIGUOUS D

- Page 293 and 294:

274 Mal et al. molecular dynamics a

- Page 295 and 296:

276 Mal et al. Assuming a rigid bod

- Page 297 and 298:

278 Mal et al. assign (segid A and

- Page 299 and 300:

280 Mal et al. References 1. Drenth

- Page 301 and 302:

282 Mal et al. 33. Jeener, J., Meie

- Page 303 and 304:

20 Dean, Kelsey, and Reik

- Page 305 and 306:

286 Werner et al. Our research has

- Page 307 and 308:

288 Fig. 1. (A) T 1, T 2 and the he

- Page 309 and 310:

290 Werner et al. tion, using gradi

- Page 311 and 312:

292 Werner et al. Fig. 3. (A) Rotat

- Page 313 and 314:

294 Werner et al. Fig. 4. (A) Line-

- Page 315 and 316:

296 Werner et al. Table 2 Models of

- Page 317 and 318:

298 Werner et al. 9. Reinhardt, D.

- Page 319 and 320:

300 Werner et al. 39. Press, W. H.,

- Page 321 and 322:

302 Boyd et al. utilize residual di

- Page 323 and 324:

304 Boyd et al. Fig. 1. (A) The sol

- Page 325 and 326:

306 Boyd et al. or significant peak

- Page 327 and 328:

308 Boyd et al. Fig. 3. Histogram o

- Page 329 and 330:

310 Boyd et al. total and NOE energ

- Page 331 and 332:

312 Boyd et al. 2. When studying mu

- Page 333 and 334:

314 Boyd et al. 4. Downing, A. K.,

- Page 335 and 336:

316 Boyd et al. 35. Schulte-Herbrug

- Page 337 and 338:

318 Yap et al. image representation

- Page 339 and 340:

320 Yap et al. modified EF-hand is

- Page 341 and 342:

322 Table 1 Angle and Distance Outp

- Page 343 and 344:

324 Yap et al. 2. Ikura, M. (1995)

- Page 345 and 346:

326 Kobayashi that S-100A1 and S-10

- Page 347 and 348:

328 Kobayashi 3.2. Coupling of Crom

- Page 349 and 350:

330 Kobayashi Fig. 2. Tricine/SDS/P

- Page 351 and 352:

332 Kobayashi 0.1% TFA at a flow ra

- Page 353 and 354:

334 Kobayashi Both recombinant S-10

- Page 355 and 356:

336 Kobayashi Fig. 6. Affinity chro

- Page 357 and 358:

20 Dean, Kelsey, and Reik

- Page 359 and 360:

340 Walsh et al. verts CaM from an

- Page 361 and 362:

342 Walsh et al. 11. Bovine serum a

- Page 363 and 364:

344 Walsh et al. Fig. 1. CaM-depend

- Page 365 and 366:

346 Walsh et al. Fig. 3. CaM-depend

- Page 367 and 368:

348 Walsh et al. 3.5. NOS Reduction

- Page 369 and 370:

350 Walsh et al. Fig. 4. CaM-depend

- Page 371 and 372:

352 Walsh et al. Fig. 6. CaM-depend

- Page 373 and 374:

354 Walsh et al. 3. Cho, M. J., Vag

- Page 375 and 376:

356 Hughes et al. The electroporati

- Page 377 and 378:

358 Hughes et al. 4. 1 M Na 2CO 3.

- Page 379 and 380:

360 Hughes et al. range, repeat ste

- Page 381 and 382:

362 Hughes et al. Table 1 Examples

- Page 383 and 384:

20 Dean, Kelsey, and Reik

- Page 385 and 386:

366 Persechini of the different CaM

- Page 387 and 388:

368 Persechini Fig. 1. Schematic re

- Page 389 and 390:

370 Persechini 2. 1 L of Terrific b

- Page 391 and 392:

372 Persechini Fig. 4. Titration wi

- Page 393 and 394:

374 Persechini Table 1 Parameters f

- Page 395 and 396:

376 Persechini Fig. 6. The [Ca 2+ -

- Page 397 and 398:

378 Persechini determined if the di

- Page 399 and 400:

380 Persechini relatively insensiti

- Page 401 and 402:

382 Persechini 18. Chafouleas, J. G

- Page 403 and 404:

384 Török et al. actions in the c

- Page 405 and 406:

386 Török et al. 3. The reaction

- Page 407 and 408:

388 Török et al. Fig. 2. Electros

- Page 409 and 410:

390 Török et al. Fig. 3. Peptides

- Page 411 and 412:

392 Török et al. Table 1 Peptide

- Page 413 and 414:

394 Török et al. Fig. 7. Nanospra

- Page 415 and 416:

396 Török et al. Fig. 9. Nanospra

- Page 417 and 418:

398 Török et al. Fig. 11. Electro

- Page 419 and 420:

400 Török et al. 3 µM FL-calmodu

- Page 421 and 422:

402 Török et al. Fig. 14. Localiz

- Page 423 and 424:

404 Török et al. Fig. 16. Indicat

- Page 425 and 426:

406 Török et al. the significantl

- Page 427 and 428:

408 Török et al.

- Page 429 and 430:

410 Index substitutes, see Fluoresc

- Page 431 and 432:

412 Index Stern-Volmer plot, 78, 81

- Page 433 and 434:

414 Index Phenothiazines, see Calmo

- Page 435:

METHODS IN MOLECULAR BIOLOGY TM •