SERVICE MANUAL MR-G57N-T-NZ - B.d.t.

SERVICE MANUAL MR-G57N-T-NZ - B.d.t.

SERVICE MANUAL MR-G57N-T-NZ - B.d.t.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

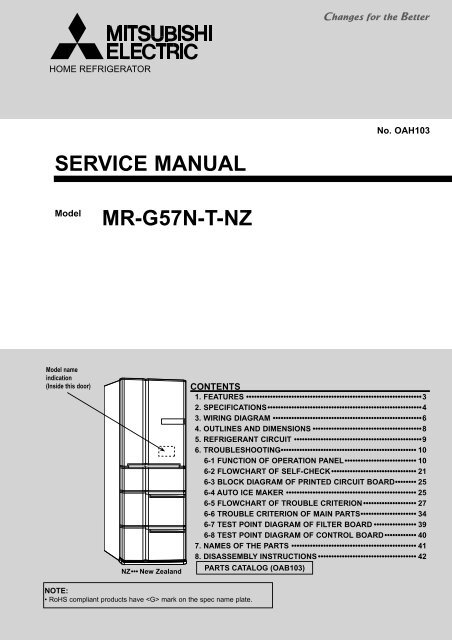

HOME REFRIGERATOR<br />

<strong>SERVICE</strong> <strong>MANUAL</strong><br />

Model <strong>MR</strong>-<strong>G57N</strong>-T-<strong>NZ</strong><br />

Model name<br />

indication<br />

(Inside this door)<br />

<strong>NZ</strong> ••• New Zealand<br />

NOTE:<br />

• RoHS compliant products have mark on the spec name plate.<br />

No. OAH103<br />

CONTENTS<br />

1. FEATURES ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••3<br />

2. SPECIFICATIONS ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••4<br />

3. WIRING DIAGRAM ••••••••••••••••••••••••••••••••••••••••••••••••••••••••6<br />

4. OUTLINES AND DIMENSIONS •••••••••••••••••••••••••••••••••••••••••8<br />

5. REFRIGERANT CIRCUIT ••••••••••••••••••••••••••••••••••••••••••••••••9<br />

6. TROUBLESHOOTING••••••••••••••••••••••••••••••••••••••••••••••••••• 10<br />

6-1 FUNCTION OF OPERATION PANEL ••••••••••••••••••••••••••• 10<br />

6-2 FLOWCHART OF SELF-CHECK •••••••••••••••••••••••••••••••• 21<br />

6-3 BLOCK DIAGRAM OF PRINTED CIRCUIT BOARD •••••••• 25<br />

6-4 AUTO ICE MAKER ••••••••••••••••••••••••••••••••••••••••••••••••• 25<br />

6-5 FLOWCHART OF TROUBLE CRITERION •••••••••••••••••••• 27<br />

6-6 TROUBLE CRITERION OF MAIN PARTS ••••••••••••••••••••• 34<br />

6-7 TEST POINT DIAGRAM OF FILTER BOARD •••••••••••••••• 39<br />

6-8 TEST POINT DIAGRAM OF CONTROL BOARD •••••••••••• 40<br />

7. NAMES OF THE PARTS ••••••••••••••••••••••••••••••••••••••••••••••• 41<br />

8. DISASSEMBLY INSTRUCTIONS ••••••••••••••••••••••••••••••••••••• 42<br />

PARTS CATALOG (OAB103)

1<br />

FEATURES<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

1. Vitamin-enhancing vegetable compartment<br />

This is a totally new-concept vegetable compartment, which enhances<br />

2<br />

the nutritional value of vegetables by irradiating LED light.<br />

2 wavelength 590nm<br />

Orange LED<br />

It encourages the<br />

vegetables to generate<br />

reducing sugar, which<br />

is the source of the<br />

1<br />

vegetable’s life, and<br />

increases vitamin C.<br />

1 This is a comparison value between the 25% drop on the 2002 conventional product of<br />

our company (<strong>MR</strong>-S46B) and the 10% increase on the 2008 new model. The sprouts<br />

were wrapped in plastic and put under LED. It was measured under the following<br />

condition: about 90 % humidity and a refrigerator temperature of about 5 ºC.<br />

The effect depends on the positional relation with other vegetables and LED light, and<br />

the amount of vegetables stored in the compartment.<br />

3<br />

Vitamin-enhancing<br />

vegetable compartment

2<br />

SPECIFICATIONS<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

Accessories<br />

Weight<br />

SPECIFICATIONS<br />

Power supply<br />

V,Hz<br />

Total capacity<br />

L<br />

Dimensions (H x W x D)<br />

mm<br />

Cabinet<br />

Food liner<br />

Cabinet<br />

Insulation<br />

Freezer door<br />

Refrigerator door<br />

Freezer<br />

Cooling system<br />

Refrigerator<br />

Evaporator<br />

Condenser<br />

Defrost system<br />

Drain<br />

Temperature control system<br />

Refrigerator compartment room light<br />

Unit<br />

Shipping<br />

Capillary tube<br />

Desiccant (molecular sieve)<br />

Refrigerant filling capacity R600a<br />

Refrigerating oil (Model)<br />

kg<br />

kg<br />

mm<br />

g<br />

g<br />

g<br />

230 V, 50 Hz<br />

613 (gross) 447 (storage)<br />

1821 x 745 x 728<br />

Acrylic resin coated steel<br />

ABS resin<br />

Foamed polyurethane (Cyclopentane)<br />

Foamed polyurethane (Cyclopentane)<br />

Foamed polyurethane (Cyclopentane)<br />

Forced air convection<br />

Forced air convection<br />

Fin and tube type<br />

Cabinet, sides, back and front flange<br />

Automatic heater defrost<br />

Automatic drainage, Forced evaporation method<br />

Automatic control<br />

240 V,10 W (E14)<br />

Free pocket (L)<br />

Free pocket (S)<br />

Bottle pocket (S)<br />

Bottle pocket (L)<br />

AUTO-shelf<br />

Two-way flexishelf<br />

Small item case<br />

Free egg shelf<br />

Slide chilled case<br />

Slide chilled case lid<br />

Versa case<br />

Aluminum tray (Versa case)<br />

Water tank (With light-type bacteria removing filter)<br />

Freezing case (upper)<br />

Freezing case (lower)<br />

Ice server<br />

Soundproof mat<br />

Ice storage bin<br />

Vegetable case<br />

Vegetable stand<br />

Sliding case (Vegetable case)<br />

Toe grille<br />

98<br />

108<br />

1.8 x 0.76 x 2820, 1.6 x 0.65 x 2820<br />

9<br />

72<br />

187 (FREOL S10)<br />

4<br />

2pcs.<br />

2pcs.<br />

1pc.<br />

1pc.<br />

2pcs.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.<br />

1pc.

ELECTRICAL PARTS SPECIFICATIONS<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

Defrosting<br />

control<br />

Fan motor<br />

Temperature control<br />

Model<br />

Dial position<br />

HI<br />

MID<br />

LOW<br />

REFRIGERATOR<br />

CHILLED<br />

LOW (Soft freezing)<br />

MID (Soft freezing)<br />

HI (Soft freezing)<br />

FREEZER<br />

ICE MAKING<br />

ICE MAKING STOP<br />

CRYSTAL ICE MAKING<br />

Model<br />

Power supply<br />

Compressor<br />

Rated input<br />

Starting current<br />

W<br />

A<br />

Running current A<br />

Winding resistance (A.T.20 )<br />

Model<br />

Motor protector<br />

Ambient temperature<br />

Time<br />

Sec.<br />

Current<br />

A<br />

Three-way valve<br />

Model<br />

Type<br />

Defrosting Model<br />

timer Specification<br />

Defrost finish<br />

Freezer Thermal fuse<br />

compartment Defrost heater<br />

Deodorizing function of defrost heater<br />

Model<br />

Type<br />

Refrigerator Input<br />

W<br />

Revolution<br />

Number of poles<br />

Model<br />

rpm<br />

Machine Input<br />

W<br />

Chamber Revolution<br />

Number of poles<br />

Water pipe heater<br />

rpm<br />

Heater<br />

(Rating)<br />

Rotational heater board<br />

Vegetable compartment heater 1<br />

Vegetable compartment heater 2<br />

Ice making tray heater<br />

Ice maker temperature<br />

Freezer Refrigerator<br />

NTC thermistor<br />

Versa Ice making Vegetable<br />

Compressor Motor damper<br />

Heater<br />

ON<br />

-23.8<br />

-21.1<br />

-18.4<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

OFF<br />

-25.4<br />

-22.7<br />

-20.0<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

OPEN<br />

1.9<br />

5.1<br />

8.4<br />

–<br />

1.3<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

5<br />

EFI100E 13DAH<br />

230 V, 50Hz<br />

45/159 (1620/4800rpm)<br />

2.0 (Current limiter)<br />

0.63/2.19 (1620/4800rpm)<br />

9.27<br />

MM3-71CCV<br />

25<br />

16 or less<br />

17.0<br />

NSCE001DC1<br />

4-phase stepping motor drive voltage DC12V<br />

SHUT<br />

0.7<br />

3.8<br />

7.0<br />

–<br />

0.1<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

OPEN<br />

–<br />

–<br />

–<br />

4.7<br />

1.5<br />

-1.6<br />

-4.3<br />

-6.2<br />

-14.5<br />

–<br />

–<br />

–<br />

Control board<br />

Microcomputer<br />

Thermistor 14 1.5<br />

70 ± 2<br />

325 (240V,177W)<br />

Not equipped<br />

UDQM002B3<br />

DC brushless motor<br />

2.4 (12V DC)<br />

1520 (12V DC)<br />

10P<br />

4715JL04WS16G51<br />

1.4 (12V DC)<br />

1450 (12V DC)<br />

4P<br />

240V-8.7W<br />

240V-8.7W<br />

240V-6.5W<br />

240V-13.2W<br />

240V-11.9W<br />

-11.6<br />

SHUT<br />

–<br />

–<br />

–<br />

3.4<br />

0.2<br />

-2.8<br />

-5.6<br />

-7.4<br />

-19<br />

–<br />

–<br />

–<br />

OPEN<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

-17.9<br />

-17.9<br />

-17.9<br />

SHUT<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

-21.9<br />

-21.9<br />

-21.9<br />

ON<br />

0.4<br />

1.9<br />

3.5<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

OFF<br />

-0.9<br />

0.7<br />

2.3<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

–

3<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

WIRING DIAGRAM<br />

I.THERMISTOR (Ice making compartment thermistor)<br />

V.THERMISTOR (Vegetable compartment thermistor)<br />

VERSA.THERMISTOR (Versa compartment thermistor)<br />

DEF.THERMISTOR (Defrost thermistor)<br />

ICE-TRAY THERMISTOR (Ice making tray thermistor)<br />

F.THERMISTOR (Freezer compartment thermistor)<br />

R.THERMISTOR (Refrigerator compartment thermistor)<br />

( SKELETON WIRING DIAGRAM )<br />

6<br />

RESISTOR<br />

ASSY

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

Freezer<br />

Compartment Door<br />

Freezer<br />

Compartment<br />

Thermal fuse<br />

F. Thermistor<br />

Defrost heater<br />

Freezer room<br />

Door switch<br />

Vegetable<br />

Compartment Door<br />

Vegetable<br />

Compartment<br />

V. heater 1<br />

Compressor<br />

Valve motor<br />

Fan motor<br />

(Freezer)<br />

Vegetable LED<br />

Motor<br />

protector<br />

Ice tray<br />

heater<br />

V. Thermistor<br />

Ice/ Versa Compartment Door<br />

Motor<br />

damper<br />

I.THERMISTOR (Ice making compartment thermistor)<br />

V.THERMISTOR (Vegetable compartment thermistor)<br />

VERSA.THERMISTOR (Versa compartment thermistor)<br />

DEF.THERMISTOR (Defrost thermistor)<br />

ICE-TRAY THERMISTOR (Ice making tray thermistor)<br />

F.THERMISTOR (Freezer compartment thermistor)<br />

R.THERMISTOR (Refrigerator compartment thermistor)<br />

Fan motor<br />

(Compressor)<br />

Ice tray<br />

thermistor<br />

I. Thermistor<br />

Ice<br />

gear box<br />

S. thermistor<br />

DEF. Thermistor<br />

Versa<br />

Compartment<br />

Water pipe heater<br />

Water pump<br />

motor<br />

( ACTUAL WIRING DIAGRAM )<br />

Refrigerator/<br />

Ice room Door<br />

switch<br />

Ice<br />

Compartment<br />

Motor<br />

damper<br />

( When the doors are closed. )<br />

7<br />

Refrigerant Compartment Door<br />

R. Thermistor<br />

Room light<br />

under side<br />

Refrigerant<br />

Compartment<br />

Room light<br />

upside<br />

Electric<br />

box<br />

N/F board<br />

TEMP.<br />

CONTROL BOARD<br />

Divider Heater (R)<br />

RESISTOR<br />

ASSY

4<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

86<br />

203<br />

196<br />

OUTLINES AND DIMENSIONS<br />

312.5<br />

310<br />

312.5<br />

318<br />

249<br />

400<br />

244<br />

655<br />

641<br />

655<br />

655<br />

607<br />

601<br />

601<br />

599<br />

376<br />

351<br />

415<br />

374<br />

367<br />

77<br />

337<br />

440<br />

396<br />

1821(Display)<br />

8<br />

8<br />

361<br />

361<br />

283.5<br />

283.5<br />

DOOR DIMENSION<br />

L(R) R(R) I S V F<br />

Hight 822 822 214 214 361 361<br />

Width 283.5 349.5 283.5 454.5 744 744<br />

104<br />

745(Display)<br />

740(Cabinet)<br />

454.5<br />

638(Pitch between the rear wheels)<br />

691(Pitch between the adjust bolts)<br />

726(Pitch between the front wheels)<br />

6<br />

6<br />

454.5<br />

362 214 822<br />

362<br />

12<br />

7<br />

7<br />

7<br />

760<br />

53<br />

41<br />

331 175<br />

39<br />

325<br />

100<br />

1821<br />

75<br />

728(Display)<br />

596<br />

655<br />

R(L) : Refrigerator compartment (Left)<br />

R(R) : Refrigerator compartment (Right)<br />

I : Ice making compartment<br />

S : Select compartment [Versa compartment]<br />

V : Vegetable compartment<br />

F : Freezer compartment<br />

8<br />

10<br />

309<br />

728<br />

142<br />

181 101<br />

290<br />

96<br />

2500<br />

633 10<br />

255<br />

195 1522<br />

REQUIRED SPACE FOR INSTALLATION<br />

37<br />

20 745 20<br />

950<br />

211<br />

165.5<br />

125<br />

125.5<br />

173<br />

~<br />

~<br />

~<br />

~<br />

206.5<br />

83.5<br />

84.5<br />

214<br />

333.5<br />

Unit : mm<br />

1121

5<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

REFRIGERANT CIRCUIT<br />

Drain pan<br />

Compressor<br />

9<br />

Dryer<br />

#150<br />

Charge pipe<br />

(Low pressure<br />

side) 6.35<br />

Condenser<br />

Charge pipe<br />

(High pressure side)<br />

4.0<br />

Muffler<br />

Evaporator<br />

Cabinet pipe<br />

Three-way<br />

valve<br />

Suction pipe<br />

Capillary tube<br />

1.8× 0.76×2820(mm)<br />

Capillary tube<br />

1.6× 0.65×2820(mm)

6<br />

TROUBLESHOOTING<br />

6-1 FUNCTION OF OPERATION PANEL<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

(1) Function of normal operation<br />

ROOM button<br />

Pressing this button selects the<br />

compartment to be displayed.<br />

Press to select the<br />

compartment before adjusting<br />

the temperature or cooling fast.<br />

SELECTION / QUICK button<br />

Pressing this button sets each compartment’s<br />

temperature.<br />

In order to cool fast,<br />

Press for 3 seconds.<br />

When the versa compartment is set at soft freezing<br />

mode, fast cooling cannot be selected.<br />

QUICK mode stops automatically<br />

• QUICK mode automatically stops in 2 hours.<br />

1<br />

When stopping QUICK mode before it automatically ends<br />

• Press .<br />

USEFUL FUNCTIONS<br />

Child Lock<br />

Press and simultaneously for 3 seconds.<br />

Stop ice making<br />

2 Press several times until is displayed.<br />

Operating mode and Temperature range<br />

Compartment Mode Temp. range<br />

Refrigerator<br />

compartment<br />

Versa<br />

compartment<br />

Ice making<br />

compartment<br />

Vegetable compartment<br />

Freezer compartment<br />

Middle<br />

Chilled<br />

Refrigerator<br />

Chilled<br />

Soft freezing (Middle)<br />

Freezer<br />

Normally<br />

Ice making stop<br />

Clear<br />

Middle<br />

Middle<br />

ECO MODE button<br />

Each compartment can be operated<br />

with energy saved.<br />

Approx. 0 to 6 °C<br />

Approx. -2 to 2 °C<br />

Approx. 0 to 6 °C<br />

Approx. -2 to 2 °C<br />

Approx. -9 to -5 °C<br />

Approx. -18 to -16 °C<br />

Approx. -21 to -17 °C<br />

Approx. -21 to -17 °C<br />

Approx. -21 to -17 °C<br />

Approx. 3 to 9 °C<br />

Approx. -21 to -17 °C<br />

The temp. range is based on the data measured at the center of each compartment<br />

with the door closed and with no food inside under the condition of ambient temperature 30 °C.<br />

10<br />

ICE SELECT button<br />

Pressing this button selects the setting<br />

of the ice making compartment.<br />

To reset the unit to the initial setting, press for 3 seconds.<br />

The refrigerator compartment, vegetable compartment, and the<br />

freezer compartment will be set to "Middle", and fast cooling<br />

operation for all compartments will be canceled.<br />

·The display extinguishes in 30 seconds<br />

after the last button is pressed.<br />

(No failure in refrigerator)<br />

·Pushing any button turns on the display<br />

again.

(2) Demonstration mode for shop display<br />

Setting<br />

Within 1 minute after power supply turns on, press the , , and simultaneously for 5 seconds<br />

with the door of the ice making compartment opened.<br />

When the setting is complete, a “beep” sound is heard and “Auto Demo Mode” is displayed.<br />

Demonstration mode is not available when the temperature of freezer compartment is –7 °C or lower.<br />

Panel operation mode during demonstration mode<br />

The panel operation mode changes to “manual” if any of the switches is pressed. It changes to "auto" if none of the switches<br />

is pressed for 45 seconds since the last time any of the switches was pressed.<br />

Manual mode: Panel indication changes according to switch operation.<br />

Auto mode: Panel indication is automatically changed.<br />

Release<br />

Simultaneously press , , and switch for about 5 seconds with the door of ice making compartment<br />

left open.<br />

When the function is released, a “beep” sound is heard.<br />

Note: Follow the procedure above to release demonstration mode as it cannot be released by simply turning<br />

on/off the power supply.<br />

(3) Fine adjustment of temperature<br />

Fine adjustment of temperature is available for refrigerator compartment, freezer compartment and versa<br />

compartment.<br />

As for versa compartment, however, it is only available when the compartment is set to or .<br />

Setting<br />

Simultaneously press , ,for about 3 seconds until a “beep” sound is heard.<br />

Room display blinks every 10 seconds in fine adjustment mode.<br />

Fine adjustments of temperature<br />

Follow the same operation procedure for temperature adjustment.<br />

Fine adjustment of temperature<br />

Normal mode Fine adjustment mode<br />

L L<br />

L M<br />

L H<br />

L M L M<br />

L M<br />

M M<br />

M H<br />

M H M H<br />

L H<br />

M H<br />

H H<br />

Release<br />

Follow the same procedure as setting and the finely-adjusted temperatures are reset for refrigerator compartment, freezer<br />

compartment and versa compartment at once.<br />

Temperature is adjusted by approximately 0.3 ~ 0.6 °C.<br />

(4) Ice making test / Self-check<br />

This function is not available during the following modes: Child lock, Demonstration, Cooking timer, Changing the<br />

rotational speed of compressor, and Error code display.<br />

Setting<br />

Press for about 5 seconds.<br />

Operation and its display<br />

While automatic ice making is testing, the indication of ice making compartment setting blinks on display.<br />

When something is faulty, the error code is indicated.<br />

Release<br />

The test automatically finishes in 10 minutes and the error code changes to temperature display.<br />

11<br />

Note: -25 °C freezing.<br />

Select the maximum setting of the<br />

temperature adjustment function for the<br />

freezer compartment.<br />

There is no particular display when the<br />

setting is selected.

(5) Service Check Function<br />

1) Outline<br />

•The chart below shows the outline of service check function.<br />

•“Service check entry” needs to be set in order to perform each check mode. After setting “service check entry,” start the<br />

setting operation of the check mode to be displayed.<br />

• blinks while performing service check function.<br />

•The display of indicates which mode is in operation.<br />

•When one of the check modes is in operation, other modes cannot be set. The mode in operation needs to be canceled<br />

before setting another mode.<br />

Once each check mode starts, it continues operating even if the door gets closed.<br />

(Open the door when releasing each mode.)<br />

Refer to the next sections about the operation procedure and display of each check mode.<br />

•In order to release “service check function entry,” follow the same procedure as setting operation during “service check<br />

function entry” or each check mode.<br />

Service check function entry<br />

Mode<br />

1) Compressor’s rotational speed change mode<br />

…The rotational speed of the compressor can be<br />

changed; The fan motor in machine chamber<br />

can be switched on and off.<br />

2) Damper Operation mode<br />

…Each damper can be opened and closed; Refrigerator<br />

fan can be switched on/off.<br />

3) Thermistor temperature check mode<br />

…The detected temperature of each thermistor can<br />

be checked.<br />

4) Error history display mode<br />

…The error occurred in the past can be checked.<br />

(1) History display mode<br />

…All the error occurred in the past can be<br />

checked in numeric order.<br />

(2) Order of occurrence mode<br />

…The newest 5 errors (at the maximum) are<br />

displayed form the newest to the older.<br />

5) Set temperature adjustment mode<br />

…Set temperature in each compartment can be<br />

adjusted.<br />

Setting / releasing method Display<br />

Door Button operation Blinking<br />

Open the<br />

ice making compartment’s<br />

door<br />

Leave the<br />

ice making<br />

compartment’s<br />

door open<br />

Leave the<br />

ice making<br />

compartment’s<br />

door open<br />

Leave the<br />

ice making<br />

compartment’s<br />

door open<br />

Leave the<br />

ice making<br />

compartment’s<br />

door open<br />

Leave the<br />

ice making<br />

compartment’s<br />

door open<br />

12<br />

Simultaneously press<br />

and for 3 seconds<br />

Setting method<br />

Display<br />

Door Button operation Lighting Blinking<br />

-<br />

-<br />

Press<br />

for 3 seconds<br />

Simultaneously press<br />

and<br />

for 3 seconds<br />

Press<br />

for 3 seconds<br />

Simultaneously press<br />

and<br />

for 3 seconds<br />

Press<br />

Press<br />

FZR<br />

“History display mode” and “Order of occurrence mode” are<br />

switched over each time is pressed.<br />

(1)<br />

VEG<br />

(2)<br />

Simultaneously press<br />

and<br />

for 3 seconds<br />

(1)<br />

(2)<br />

(3)<br />

(4)<br />

(4)<br />

(4)<br />

(5)

2) Compressor’s rotational speed change mode<br />

Setting<br />

With the ice making compartment’s door opened, simultaneously press and for 3 seconds until a “beep”<br />

sound is heard. starts to blink.<br />

With the door opened, press for 3 seconds to start compressor’s rotational speed change mode.<br />

Once this mode starts, it continues operating even if the door gets opened.<br />

Compressor’s rotational speed change mode is not available during demonstration mode, thermistor temperature mode,<br />

temperature adjustment mode, error history mode, or when child lock is effective.<br />

Display during compressor’s rotational speed change mode<br />

During compressor’s rotational speed change mode, blinks and lights up.<br />

Display of rotational speed<br />

• Compressor’s rotational speed is divided into ones’ place and tens’ place when it is displayed.<br />

• One of the values (8/4/2/1) is assigned to each indicator of both tens’ place and one’ place on the display panel. The sum of<br />

the corresponding values of the lighting indicators is the compressor’s rotational speed.<br />

Compressor’ s<br />

rotational speed<br />

Tens’ place<br />

…<br />

Temperature<br />

Adjustment Display<br />

Lighting<br />

Corresponding<br />

values<br />

REF CHIL 8 4<br />

SOFT FZR 2 1<br />

e.g.) Compressor’s rotational speed 56rps, Fan in machine chamber OFF<br />

Tens’ place "5"<br />

(=4+1)<br />

13<br />

Display during<br />

Compressor’ s<br />

rotational speed change mode<br />

Fan in machine<br />

chamber<br />

ON/OFF<br />

Ice Making Mode<br />

Display<br />

Compressor’ s<br />

rotational speed<br />

Ones’ place<br />

…<br />

Blinking<br />

Corresponding<br />

values<br />

REG QCK 8 4<br />

CRL STOP 2 1<br />

Fan in machine<br />

chamber OFF<br />

Ones’ place "6"<br />

(=4+2)<br />

Changing the rotational speed<br />

After setting this mode, compressor’s rotational speed changes every time button is pressed.<br />

Rotational speed (rps) is divided into ones’ place and tens’ place when it is displayed.<br />

(Basically the compressor starts operation at level 10, however, it may be different depending on models, or as a result of<br />

specification change.<br />

<br />

Normal<br />

Level 0 Level 1 Level 2 Level 3 Level 4 Level 5<br />

Low speed<br />

Rotational speed can be changed only when the compressor is in operation. While the compressor stops, rotational speed is<br />

not displayed, and button operation is not effective. When the compressor stops, unplug the power code, and wait for<br />

a few minutes, then plug it again.<br />

Operation sound may get increase in the process of changing rotational speed, but that is not dysfunction. Check the sound<br />

level when rotational speed is stabilized.<br />

Switching ON/OFF the machine chamber fan motor<br />

In this mode, fan motor in machine chamber can be switched on and off at each press of .<br />

Release<br />

The ON/OFF state is displayed with<br />

on the display panel.<br />

Machine chamber fan motor Display of ECO<br />

ON<br />

Lighting<br />

OFF<br />

Not lighting<br />

Level 6 Level 7 Level 8 Level 9 Level 10<br />

High speed<br />

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”<br />

sound is heard. The screen returns to the normal temperature display.<br />

The function is automatically released in one hour.<br />

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure<br />

above for protection of the compressor.

3) Damper Operation Mode<br />

Setting<br />

With the ice compartment door opened, press<br />

heard. blinks.<br />

and simultaneously for 3 seconds until a “beep” sound is<br />

With the door opened, press and simultaneously for 3 seconds until a “beep” sound is heard.<br />

Damper operation mode starts. Once this mode starts, it continues operating even if the door gets closed.<br />

Damper operation mode is not available during demonstration mode, thermistor temperature mode, compressor’s rotational<br />

speed change mode, temperature adjustment mode, error history mode, or when child lock is effective.<br />

Display during damper operation mode<br />

During damper operation mode, blinks and lights up.<br />

Control state display of each damper<br />

a)Damper<br />

serial number<br />

Light<br />

b)State of damper<br />

upper: the damper<br />

lower: the next damper<br />

(Operating: Blinks)<br />

During<br />

damper<br />

operation<br />

c)Refrigerator<br />

fan ON/OFF<br />

14<br />

Blinks<br />

d)Display during damper<br />

operation “Blinks”<br />

a) Damper serial number<br />

The room display on the display panel corresponds to the values representing damper types. The room display indicators<br />

and their corresponding values (8/4/2/1) are shown the tables below.<br />

Each serial number is assigned to each compartment (thermistor), which is used in thermistor temperature mode and<br />

set temperature adjustment mode besides damper operation mode. The sum of the corresponding values of the lighting<br />

indicators is the damper’s serial number.<br />

Room Display Corresponding values<br />

REF VR 8 4<br />

VEG FZR 2 1<br />

Serial number Assigned compartment Damper operation mode<br />

1 Refrigerator compartment<br />

2 Slide chilled compartment<br />

3 Ice making compartment<br />

4 Versa compartment<br />

5 Vegetable compartment<br />

6 Freezer compartment<br />

7 Defrosting<br />

8 Ice tray<br />

9 Outdoor air<br />

10 Deodorization<br />

/ : SW operation is effective / ineffective<br />

b) State of damper<br />

REF and CHIL displayed on the upper part indicate the present state of the damper, and SOFT and FZR displayed on the<br />

lower part indicate the state of the next damper operation.<br />

REF and SOFT displayed on the left side indicate that the damper is open, and CHIL and FZR displayed on the right side<br />

indicate that the damper is close.<br />

Present<br />

Next<br />

REF CHIL<br />

SOFT FZR<br />

Open Close<br />

c) ON/OFF state of refrigerator fan motor<br />

ECO indicates the ON/OFF state of refrigerator fan motor.

Opening and closing dampers<br />

(1) Press to select the damper to be set. Each press of the button makes a “beep” sound and changes the kind of<br />

dampers. The serial number described in a) indicates the selected damper.<br />

The selected damper is displayed using the serial number (1: refrigerator ~ 10: deodorization) in numeric order repeatedly.<br />

Refrigerator damper slide chilled compartment damper ice making compartment damper outdoor air deodorization damper<br />

Slide chilled compartment, vegetable compartment, defrosting, ice tray, outdoor air, and deodorization can be selected;<br />

however, it is ineffective in damper operation mode.<br />

Status display of damper<br />

1. REF and SOFT displayed on the left side indicate that the damper is open, and CHIL and FZR displayed on the right side<br />

indicate that the damper is close.<br />

2. REF and CHIL displayed on the upper part indicate the present state of the damper, and SOFT and FZR displayed on the<br />

lower part indicate the state of the next damper operation.<br />

3. The selected status (open or close) of both present and next damper states lights up when the selected damper is operational.<br />

However, FZR keeps lighting up as the next state when the selected damper is not operational.<br />

Present<br />

Next<br />

REF CHIL<br />

SOFT FZR<br />

Open<br />

Close<br />

4. When the selected damper is in operation, the indicator for the present state blinks.<br />

5. When any of the dampers, including the one that is not selected, is in operation, "d) display during damper operation" blinks.<br />

(2) Press , and then select "SOFT" to open the damper or "FZR" to close the damper.<br />

(3) Press for 3 seconds to operate the damper. (A “beep” sound is heard when the setting has been conveyed.)<br />

Setting of the operating damper cannot be changed.<br />

Damper operation stops automatically. (Blinking changes to lighting.)<br />

e.g.) When changing the damper of ice making compartment from “CLOSE” state to “OPEN” state, select the indicators as<br />

shown below and press for 3 seconds.<br />

Switching ON/OFF the refrigerator fan motor in the unit<br />

In this mode, each press of switches on and off the refrigerator fan motor.<br />

The ON/OFF state of the refrigerator fan motor is represented with .<br />

"ECO" display Fan motor in the unit<br />

Lighting ON<br />

Not lighting OFF<br />

Release<br />

a)Serial b)State of damper<br />

number Present “CHIL” : Close<br />

“3” : Ice making Next “SOFT” : Open<br />

compartment<br />

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep” sound is<br />

heard. The screen returns to the normal temperature display.<br />

The function is automatically released in one hour.<br />

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure<br />

above for protection of the compressor.<br />

15<br />

c)Refrigerator fan<br />

Lighting : ON<br />

d)

4) Thermistor temperature check mode<br />

Setting<br />

With the ice compartment door opened, press and simultaneously for 3 seconds until a “beep” sound is<br />

heard. blinks.<br />

With the door opened, press for 3 seconds.<br />

Thermistor temperature check mode starts. Once this mode starts, it continues operating even if the door gets closed.<br />

Thermistor temperature check mode is not available during demonstration mode, Compressor's rotational speed change<br />

mode, set temperature adjustment mode, error history display mode, or when child lock is effective.<br />

Display during thermistor temperature check mode<br />

During thermistor temperature check mode, blinks and lights up.<br />

Displaying the thermistor temperature<br />

The kind and temperature of thermistor is displayed on the operation panel.<br />

Outside temperature detected by thermistor may be a little different from the actual one due to the influence of the<br />

temperature in the refrigerator.<br />

a)Thermistor<br />

Serial number<br />

b)Thermistor<br />

temperature<br />

tens’ place<br />

a) Thermistor serial number<br />

The room display on the display panel corresponds to the values representing thermistor types. The room display indicators<br />

and their corresponding values (8/4/2/1) are shown the tables below.<br />

Each serial number is assigned to each compartment (thermistor), which is used in damper operation mode and<br />

set temperature adjustment mode besides thermistor temperature mode. The sum of the corresponding values of the<br />

lighting indicators is the thermistor’s serial number.<br />

Room Display Corresponding values<br />

REF VR 8 4<br />

VEG FZR 2 1<br />

Light<br />

c)Thermistor<br />

temperature<br />

± signs<br />

Display during<br />

thermistor temperature<br />

check mode<br />

Serial number Assigned compartment Thermistor temperature check mode<br />

1 Refrigerator compartment<br />

2 Slide chilled compartment<br />

3 Ice making compartment<br />

4 Versa compartment<br />

5 Vegetable compartment<br />

6 Freezer compartment<br />

7 Defrosting<br />

8 Ice tray<br />

9 Outdoor air<br />

10 Deodorization<br />

/ : SW operation is effective / ineffective<br />

b) Thermistor temperature tens’ place<br />

Tens’ place of thermistor temperature is indicated on the display part which is usually used for temperature adjustment of<br />

slide chilled compartment.<br />

Display of REF / CHIL / SOFT / FZR corresponds to the values, 8/4/2/1. The sum of the corresponding values of the blinking<br />

indicators is the tens’ place of thermistor temperature.<br />

Temperature Adjustment Display Corresponding values<br />

REF CHIL 8 4<br />

No indicator lights up when it is “0”.<br />

SOFT FZR 2 1<br />

c) Thermistor temperature signs<br />

Plus and minus signs of thermistor temperature are indicated on the display which is usually used for "ECO" mode.<br />

ECO Thermistor temperature signs<br />

Lighting -<br />

Not lighting +<br />

16<br />

d)Thermistor<br />

temperature<br />

ones’ place<br />

Blink

d) Thermistor temperature ones’ place<br />

Ones’ place of thermistor temperature is indicated on the display part which is usually used for ice making setting.<br />

Display of REG / QCK / CRL / STOP corresponds to the values, 8/4/2/1. The sum of the corresponding values of lighting<br />

indicators is the ones’ place of thermistor temperature.<br />

Ice making setting display Corresponding values<br />

REG QCK 8 4 No indicator lights up when it is “0”.<br />

CRL STOP 2 1<br />

e.g.) When freezer compartment thermistor is –25 ºC.<br />

a)Serial<br />

number<br />

“6” : Freezer<br />

Changing the thermistor on display<br />

b)Tens’ place<br />

“2”<br />

c)Sign<br />

“-”<br />

d)Ones’ place<br />

“5” (=4+1)<br />

While thermistor temperature is on display, press .<br />

Each press of the button makes a “beep” sound and changes the kind of thermistor.<br />

Each thermistor is displayed using the serial numbers described in a) in numeric order repeatedly (1: refrigerator<br />

compartment ~ 10: deodorization).<br />

Refrigerator compartment slide chilled compartment ice making compartment versa compartment vegetable<br />

compartment freezer compartment defrosting ice tray outdoor air deodorization damper<br />

When this mode is set, the display always starts from the refrigerator thermistor.<br />

Slide chilled compartment thermistor can be selected; however, it is ineffective because slide chilled compartment thermistor<br />

is not installed.<br />

Deodorization can be selected; however, it is ineffective in thermistor temperature check mode.<br />

Release<br />

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”<br />

sound is heard. The screen returns to the normal temperature display.<br />

The function is automatically released in one hour.<br />

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure<br />

above for protection of the compressor.<br />

5) Error history display mode<br />

The errors occurred in the past can be observed as an error history. Use this mode when the actual problem of<br />

the refrigerator is different from the error that was displayed at the service-call received.<br />

Error history display mode offers two ways of display. One of the two is “history display mode,” which shows all<br />

errors occurred in the past in numeric order of the error code; the other is “order of occurrence mode,” which<br />

shows the newest 5 errors (at the maximum) from the newest to the older.<br />

Error history display mode starts with “history display mode.”<br />

Setting<br />

With the ice compartment’s door opened, press and simultaneously for 3 seconds until a “beep” sound is<br />

heard. blinks.<br />

With the door opened, press and simultaneously for 3 seconds until a “beep” sound is heard.<br />

History error mode starts. Once this mode starts, it continues operating even if a door gets opened.<br />

Display during error history display mode<br />

During error history display mode, blinks and lights up.<br />

Display of error history information.<br />

Light<br />

a)Mode display b)Error code<br />

“History display Tens’ place<br />

mode” or<br />

“Order of occurrence<br />

mode”<br />

Display during error<br />

history display mode<br />

c)Error code<br />

Ones’ place<br />

a) Mode display<br />

Display the selected mode between “history display mode” and “order of occurrence mode.”<br />

b) Error code tens’ place<br />

It displays the tens’ place of error code.<br />

It applies the same representative method as the errorl display of self-check.<br />

c) Error code ones’ place<br />

It displays the tens’ place of error code.<br />

It applies the same representative method as the error display of self-check.<br />

17<br />

Blink

Switching over the mode<br />

Press to select one of the error history display modes. Each press of the button makes a “beep” sound and<br />

switches over between “history display mode” and “order of occurrence mode.”<br />

Compartment Error history display mode<br />

FZR History display mode Display all errors occurred in the past in numeric order of the error code<br />

VEG Order of occurrence mode Display the newest 5 errors (at the maximum) from the newest to the older.<br />

Display method<br />

Display method of the error code is the same as self check error display. (Refer to 6-2(3)); however, all indicators used for<br />

the display of error code light up simultaneously for 3 seconds before the first error code is displayed (“pre- display”).<br />

e.g.) When errors occurred in the following order:<br />

fan motor error (E31) communication error of operation panel (E01) refrigerator thermistor error (E13)<br />

•Display during history display mode<br />

Errors are displayed in numeric order.<br />

Tens’ place<br />

Ones’ place<br />

Error code Pre-display<br />

3sec.<br />

0.5<br />

sec.<br />

•Display during order of occurrence mode<br />

Errors are displayed from the newest to the older.<br />

Tens’ place<br />

Ones’ place<br />

E01 E13 E31<br />

0.5<br />

sec.<br />

Repetition<br />

When no error occurred in the past, error code is not displayed.<br />

Check points and resetting the error history<br />

Check and take appropriate measures according to the procedures as stated in 6-2(1).<br />

Conduct self-check to confirm there is no dysfunction. (Make sure all connectors are connected properly and there are<br />

no loose connection.)<br />

Refer to “ Setting” above and activate the error history mode again. With the ice making compartment’s door<br />

opened, press for 3 seconds to reset error history. (Resetting the error history is completed.) If it is completed<br />

correctly, no error code would be displayed.<br />

Release<br />

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”<br />

sound is heard. The screen returns to the normal temperature display.<br />

The function is automatically released in one hour.<br />

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure<br />

above for protection of the compressor.<br />

18<br />

0.5<br />

sec.<br />

5sec. 5sec. 5sec.<br />

Error code Pre-display E13 E01 E31<br />

3sec.<br />

0.5<br />

sec.<br />

0.5<br />

sec.<br />

Repetition<br />

0.5<br />

sec.<br />

0.5<br />

sec.<br />

0.5<br />

sec.<br />

Pre-display<br />

3sec.<br />

Pre-display<br />

5sec. 5sec. 5sec. 3sec.

6) Set temperature adjustment mode<br />

Switch operation on the operation panel changes the set temperature in each compartment.<br />

Setting<br />

With the ice compartment door opened, press<br />

blinks.<br />

and simultaneously for 3 seconds until a “beep” sound is heard.<br />

With the door opened, press and simultaneously for 3 seconds until a “beep” sound is heard.<br />

Set temperature adjustment mode starts. Once this mode starts, it continues operating even if the door gets closed.<br />

Display during set temperature adjustment mode<br />

During set temperature adjustment mode, blinks and lights up.<br />

Control state display of each compartment<br />

a)Compartment<br />

serial number<br />

Light<br />

b)Set temperature adjustment level<br />

a) Compartment serial number<br />

Serial number of the selected compartment for set temperature adjustment is displayed on the part that<br />

are usually used for room display.<br />

Each serial number is assigned to each compartment that will be used in set temperature adjustment mode besides damper<br />

operation mode and thermistor temperature check mode.<br />

The sum of the corresponding values of the lighting indicators is the compartment serial number.<br />

Room display Corresponding values<br />

REF VR 8 4<br />

VEG FZR 2 1<br />

Serial number Assigned compartment Set temperature adjustment mode<br />

1 Refrigerator compartment<br />

2 Slide chilled compartment<br />

3 Ice making compartment<br />

4 Versa compartment<br />

5 Vegetable compartment<br />

6 Freezer compartment<br />

7 Defrosting<br />

8 Ice tray<br />

9 Outdoor air<br />

10 Deodorization<br />

/ : SW operation is effective / ineffective<br />

b) Set temperature adjustment level<br />

Adjustment level of the set temperature is displayed on the display part that is usually used for temperature adjustment.<br />

Adjusting the set temperature<br />

19<br />

Display during set<br />

temperature<br />

adjustment mode<br />

(1) Select the compartment with button.<br />

(2) Each press of the button makes a “beep” sound and changes the compartment to adjust the set temperature.<br />

Each compartment will be displayed using the serial numbers (1: refrigerator compartment~ 6: Freezer<br />

compartment) in numeric order repeatedly.<br />

Refrigerator compartment slide chilled compartment versa compartment ice making compartment<br />

vegetable compartment freezer compartment<br />

Set temperature adjustment operation of slide chilled compartment is possible; however, it is ineffective because slide chilled<br />

compartment thermistor is not installed.<br />

Blink

(3) Select the adjustment level of set temperature with .<br />

Each press of the button makes a “beep” sound and changes the adjustment level of set temperature.<br />

There are 5 adjustment levels of set temperature ( 2 & 0), and the selected level is displayed.<br />

Adjustment level<br />

+2<br />

+1<br />

Temperature<br />

adjustment display<br />

REF<br />

CHIL<br />

Change of the set<br />

temperature<br />

About +2 ºC<br />

About +1 ºC<br />

±0 No change<br />

-1 About -1 ºC<br />

SOFT<br />

-2 About -2 ºC<br />

FZR<br />

Release<br />

With the ice making compartment’s door opened, press and simultaneously for 3 seconds until a “beep”<br />

sound is heard. The screen returns to the normal temperature display.<br />

The function is automatically released in one hour.<br />

Although unplugging and plugging the power code can release this function, it is recommended to follow the procedure<br />

above for protection of the compressor.<br />

Door Buzzer System :<br />

Door buzzer has been installed so that one will not forget to close the door.<br />

•The buzzer rings in the following conditions:<br />

1. When door is left open.<br />

2. When refrigerator fan motor or machine chamber fan motor is abnormal.<br />

3. When there is possibility that the door of freezer compartment is not closed securely.<br />

1. When door is left open<br />

Every 1 minute, for 4 minutes<br />

After 5 minutes<br />

Buzzer<br />

"Beep beep" 4 times<br />

“"Beep beep" continuously<br />

2. Refrigerator fan motor or machine chamber fan motor is abnormal "Beep beep" 2 times<br />

3. When there is possibility that the door of freezer compartment is not closed securely "Beep beep" 3 times<br />

1. The buzzer rings to inform the open door when the door of ice making compartment, refrigerator compartment, or freezer<br />

compartment is left open for more than one minute.<br />

•The buzzer rings every minute. After 5 minutes, the buzzer rings continuously.<br />

•The buzzer will stop ringing as soon as the door is closed.<br />

•When the buzzer does not stop even if all the doors are closed, door switch may be abnormal.<br />

The buzzer can be stopped by the following operations.<br />

Perform the ice making test operation.<br />

(Note: If the test is conducted with water in the ice tray, water may fall into the ice storage bin because the tray is rolled<br />

over in the ice making operation.)<br />

2. Buzzer sounds when a trouble is found in refrigerator fan motor or in machine chamber fan motor. The buzzer sounds<br />

every time the door is closed until normal operation is obtained.<br />

(Check the error code by following the steps in Specification of display in self-check result on page 21.)<br />

3. Buzzer sounds when there is possibility that the door of freezer compartment is not closed securely. The assumption is<br />

made in either of the following conditions.<br />

When the door of freezer compartment is closed, and the temperature inside did not lower after a predetermined time.<br />

The temperature of freezer compartment is abnormally high, and the temperature of evaporator is abnormally low continuously<br />

for a long time.<br />

Room light :<br />

• Room light inside the refrigerator compartment lights when the door of refrigerator compartment or ice making compartment<br />

is open.<br />

• When room light is lighted continuously for more than 60 minutes, it is turned off to prevent heating.<br />

• The protection is released when doors of refrigerator compartment and ice making compartment are closed. Then, room<br />

light will be lighted the next time at normal timing.<br />

20

6-2 FLOWCHART OF SELF-CHECK<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

(1) Troubleshooting with self-check<br />

This refrigerator has self-check feature to clarify and indicate where & what the trouble is.<br />

You can perform operation checks and identify malfunction of electric or electronic parts.<br />

Error history is recorded and can be displayed by the refrigerator.<br />

Yes<br />

Self-check<br />

(current displayed error)<br />

Display error<br />

history.<br />

Self-check Error history mode (Refer to 6-1.(5)5))<br />

Operate the ice-making test.<br />

(Current displayed error: Refer to<br />

in the table below.)<br />

The display of ice making compartment<br />

setting will blink during the test.<br />

Is error displayed?<br />

Yes<br />

Locate the trouble according to error<br />

display. (See page 22-24)<br />

Unplug the power cord from outlet.<br />

Repair /replace defective part(s)<br />

according to error display.<br />

Self-check<br />

Plug the power cord into outlet.<br />

(Current displayed error:<br />

Refer to in the table below.)<br />

Is error displayed?<br />

No<br />

Was more than one error<br />

displayed during repair?<br />

Yes<br />

Was the error which was informed from<br />

user by telephone turned on displayed.<br />

And was treatment performed?<br />

Yes<br />

Self-check is finished.<br />

During the ice-making<br />

test mode, watch the<br />

operation ice-maker<br />

gear box and water<br />

pump in refrigerator.<br />

No<br />

No<br />

No<br />

*Wait 10 minutes<br />

before plugging<br />

the cord once<br />

it's unplugged.<br />

(if the cord is<br />

plugged in within<br />

10 minutes, error<br />

may be displayed.)<br />

Perform error<br />

history mode.<br />

Perform error<br />

history mode.<br />

Self-check and error display method and operation<br />

Item<br />

Ice making test operation.<br />

All items except (*6) listed<br />

up on the table at page<br />

24 will be checked.<br />

Power input.<br />

All items except (*6) listed<br />

up on the table at page<br />

24 will be checked.<br />

Error history<br />

21<br />

Problem may recover automatically.<br />

Perform the following if error is not displayed<br />

before treatment or the error which was informed<br />

from user by telephone is not displayed.<br />

Yes<br />

Set the error display mode.<br />

Is error displayed?<br />

Yes<br />

Perform self-check<br />

procedures through .<br />

Reset the error history.<br />

(Refer to 6-1.(5)5))<br />

Is error displayed?<br />

No<br />

No<br />

Release error displayed<br />

mode, and the self-check<br />

is finished.<br />

Release error display<br />

mode and perform the<br />

self-check again.<br />

(go to )<br />

Note1: Self-check cannot detect abnormalities in the following parts.<br />

See page 27-39 for troubleshooting.<br />

Door switch<br />

Motor damper<br />

Heater (Water pipe / Vegetable compartment heater, etc.)<br />

Water pump motor<br />

Note2: If any abnormality is found when plugging the power cord,<br />

compressor and fan motor are suspended for 10 minutes.<br />

Note3: The alarm beeps when some abnormalities (motor-locked) have<br />

occurred at the refrigerator fan motor or machine chamber fan<br />

motor restarts its normal operation.<br />

Note4: If any abnormality occurs in compressor's inverter circuit,<br />

the compressor and the refrigerator fan motor stop for 10 minutes<br />

(not only when plugging the power cord).<br />

Operation method Display or self-check operation Display time Others<br />

Press the switch.<br />

for 5 seconds.<br />

(“beep” is heard)<br />

Plug the power<br />

cord into outlet.<br />

Refer to 6-1(5)5)<br />

Error history<br />

display mode.<br />

1.Conduct the automatic ice making test.<br />

(The display of ice making compartment<br />

setting is blinked)<br />

2.When trouble is found, all error codes<br />

are displayed.<br />

3.When error is not found, nothing is<br />

displayed.<br />

1.When trouble is found, all trouble except<br />

E50 ~ E55 and displayed.<br />

2.When error is not found, nothing is<br />

displayed.<br />

1.When trouble is found, all trouble except<br />

E50 ~ E55 and displayed.<br />

2.When error is not found, nothing is<br />

displayed.<br />

For 10 minutes<br />

after setting.<br />

For 10 minutes<br />

after power is<br />

supplied.<br />

For one hour<br />

after setting,<br />

or until mode<br />

is released.<br />

Release of self-check display mode<br />

Self-check finishes automatically. Error cord display is automatically released 10 minutes later.<br />

Self-check is not available<br />

during child lock, cooking<br />

timer, changing the rotational<br />

speed of compressor,<br />

checking the temperature<br />

of thermistor, damper operation<br />

and demonstration<br />

modes.<br />

Self-check is not available<br />

during demonstration<br />

mode.<br />

Self-check is not available<br />

during child lock, cooking<br />

timer, changing the rotational<br />

speed of compressor,<br />

checking the temperature<br />

of thermistor, damper operation<br />

and demonstration<br />

modes.

(2) Timing in self-check<br />

Trouble of Defrost heater : Self-check is conducted after defrosting.<br />

(Make sure to confirm the display before unplugging the power cord<br />

because it is automatically reset once the power cord is unplugged.)<br />

Trouble of Ice maker : Press the switch on the panel for 5 seconds. (Ice making test mode.)<br />

The setting of ice making compartment blinks on display during the test operation.<br />

Trouble of Fan motor : Open the door and then closed it.<br />

When abnormality is found in fan motor, buzzer sound is heard every time the door is closed.<br />

Trouble of Inverter : Check the error when compressor starts up or is operating.<br />

Trouble of Thermistor : Self-check is continuously working<br />

(3) Error display and trouble locating<br />

1. Display details<br />

After conducting the self-check referring to 6-2(1), flashes repetitively and the error code will be displayed divided into<br />

tens’ place and ones’ place if any.<br />

When two or more errors occur, they are displayed alternately. The error whose code has smaller number has priority to<br />

be displayed first. There are 0.5 seconds intervals between the error codes<br />

Self-check<br />

b)Error code<br />

Tens’ place<br />

…<br />

Temperature Adjustment Display Corresponding values<br />

REF CHIL 8 4<br />

SOFT FZR 2 1<br />

For 2 minutes in self-check, a high-tone sound is heard due to the operation check of damper.<br />

2. Check point and treatment<br />

22<br />

c)Error code<br />

Ones’ place<br />

…<br />

Flashing<br />

Ice Making Mode Display Corresponding values<br />

REG QCK 8 4<br />

CRL STOP 2 1<br />

Ex.) In case the errors of refrigerator thermistor (E13) and ice maker gear box (E33) are happening simultaneously.<br />

Tens’ place<br />

Ones’ place<br />

Error code<br />

Display Error<br />

code<br />

Display<br />

Tens' place Ones' place<br />

Trouble<br />

E13 E33 E13 E33<br />

5sec.<br />

0.5<br />

sec.<br />

Detecting method<br />

(*3)<br />

0.5<br />

sec.<br />

5sec. 5sec.<br />

Testing (*1) Ice maker is under testing<br />

Error display<br />

E 01<br />

E 02<br />

E 03<br />

E 10<br />

E 11<br />

E 12<br />

E 13<br />

CRL<br />

STOP<br />

CRL STOP<br />

(*4)<br />

Communication<br />

error of<br />

operation panel<br />

Communication<br />

error of inverter<br />

Trouble of<br />

model judgement<br />

Trouble of ice<br />

making tray<br />

thermistor<br />

When the following communication<br />

errors occur<br />

between control board and<br />

operation P.C. board:<br />

•They transmit and receive<br />

data that has nothing to<br />

do with settings.<br />

•They cannot transmit<br />

and receive data each<br />

other for about 2 seconds.<br />

When abnormality is found in the<br />

communication between refrigerator<br />

control circuit and inverter<br />

control circuit in control board.<br />

(When they do not transmit and<br />

receive data for 10 seconds.)<br />

When the model of<br />

control board is different<br />

from the one of operation<br />

P.C. board.<br />

When there is a short<br />

or open circuit in the ice<br />

making tray thermistor.<br />

0.5<br />

sec.<br />

Check point Treatment Control<br />

1. Connector CN8K, CN7S, CN4D on control<br />

board<br />

5-pin wire to wire connector (hinge)<br />

5-pin connector on operation P.C. board<br />

2. Trouble of control board and operation<br />

P.C. board<br />

Repair the<br />

contact failure.<br />

Replace<br />

Keep the same operation<br />

as the one before the<br />

communication error has<br />

occurred.<br />

Replace the Compressor OFF.<br />

control board.<br />

1. Check the model name of control board Replace Keep operating the unit,<br />

and conduct error code<br />

2. Check the operation P.C. board. Replace indication only.<br />

1. Connector CN7S on control board, Ice gear<br />

box 6-pin wire to wire connector, 8-pin wire<br />

to wire connector<br />

Repair the<br />

contact failure.<br />

FZR 2. Check the resistance of thermistor. Replace<br />

Trouble of<br />

freezer compartment<br />

thermistor<br />

Trouble of<br />

defrost<br />

thermistor<br />

When there is a short<br />

or open circuit in the<br />

freezer<br />

compartment thermistor.<br />

When there is a short<br />

or open circuit in the<br />

defrost thermistor.<br />

1. Connector CN7S on control board,<br />

6-pin wire to wire connector<br />

Repair the<br />

contact failure.<br />

When the compartment door<br />

has been closed for 3 hours<br />

and when freezer compartment<br />

thermistor is -10 or<br />

less, ice-detecting operation<br />

starts.<br />

After 10 minutes off, the<br />

compressor repeats 30-<br />

minute ON and 20-minute<br />

OFF.<br />

FZR STOP<br />

2. Check the resistance of thermistor. Replace<br />

1. Connector CN7S on control board, Repair the The defrost heater won’t<br />

2-pin wire to wire connector<br />

contact failure. be turned ON.<br />

FZR CRL 2. Check the resistance of thermistor. Replace<br />

Trouble of When there is a short 1. Connector CN7S on control board, Repair the Synchronize the open/<br />

refrigerator or open circuit in the 6-pin wire to wire connector<br />

contact failure. close status of R damper<br />

FZR CRL<br />

thermistor<br />

STOP<br />

refrigerator compartment<br />

thermistor.<br />

2. Check the resistance of thermistor. Replace<br />

with that of compressor<br />

ON/OFF.

Display Error Display<br />

code Tens' place Ones' place<br />

Trouble<br />

Detecting method<br />

(*3)<br />

Trouble of When there is a short or<br />

versa com- open circuit in the versa<br />

partmentther- compartment thermistor.<br />

QCK mistor<br />

Self-check<br />

Error display<br />

E 15<br />

E 16<br />

E 17<br />

E 18<br />

E 30<br />

E 31<br />

E 32<br />

E 33<br />

E 34<br />

E 41<br />

FZR STOP<br />

FZR CRL<br />

QCK<br />

QCK<br />

FZR CRL STOP<br />

FZR<br />

REG<br />

Trouble of veg- When there is a short<br />

etablecompart- or open circuit in the<br />

ment thermistor vegetable compartment<br />

thermistor .<br />

Trouble of ice<br />

making compartment<br />

thermistor<br />

Trouble of<br />

outside air<br />

thermistor<br />

Trouble of<br />

defrost heater<br />

(*6)<br />

When there is a short<br />

or open circuit in the ice<br />

making compartment<br />

thermistor.<br />

When there is a short or<br />

open circuit in the outside<br />

air thermistor.<br />

When defrosting is not<br />

finished in 2 hours.<br />

23<br />

Check point Treatment Control<br />

1. Connector CN7S on control board,<br />

6-pin wire to wire connector<br />

Repair the<br />

contact failure.<br />

2. Check the resistance of thermistor. Replace<br />

1. Connector CN7S on control board, 4-pin<br />

wire to wire connector<br />

Repair the<br />

contact failure.<br />

2. Check the resistance of thermistor. Replace<br />

1. Connector CN7S on control board,<br />

6-pin, 9-pin wire to wire connector<br />

Repair the<br />

contact failure.<br />

2. Check the resistance of thermistor. Replace<br />

1. Connector CN2A on control board<br />

Defrost heater plug and receptacle,<br />

1-pin wire to wire connector<br />

Thermal fuse 2-pin, 4-pin wire to wire<br />

connector<br />

Replace the<br />

operation<br />

P.C. board.<br />

Repair the<br />

contact failure.<br />

SOFT FZR 2. Check the resistance of defrost heater. Replace<br />

3. Check the continuity of thermal fuse. Replace<br />

SOFT FZR STOP<br />

SOFT FZR CRL<br />

Trouble of<br />

refrigerator<br />

fan motor<br />

Trouble of<br />

machine<br />

chamber fan<br />

motor<br />

Trouble of ice<br />

maker gear<br />

box<br />

•When motor doesn’t<br />

rotate even though<br />

power is on.<br />

•When the waveform,<br />

which indicates the<br />

rotation times of motor,<br />

cannot be detected.<br />

•When motor doesn’t<br />

rotate even though<br />

power is on.<br />

•When the waveform,<br />

which indicates the<br />

rotation times of motor,<br />

can not be detected.<br />

When the gear box<br />

operation is not finished<br />

in 30 seconds.<br />

(T0: Defrost thermistor<br />

temperature at power<br />

input, T1: Defrost thermistor<br />

temperature when<br />

15 minutes have passed<br />

from the power input)<br />

•When the difference<br />

between<br />

T0 and T1 is T0 T1. (*5)<br />

1. Connector CN6D on control board,<br />

Refrigerator fan motor 4-pin wire to wire<br />

connector<br />

Repair the<br />

contact failure.<br />

2. Check refrigerator fan motor operation. Replace<br />

1. Connector CN4D on control board,<br />

4-pin connector, 4-pin wire to wire connector<br />

2. Check machine chamber fan motor<br />

operation.<br />

1. Connector CN8K, CN7S on control board, Ice gear box<br />

6-pin wire to wire connector, 8-pin wire to wire connector<br />

Repair the<br />

contact failure.<br />

Replace<br />

•When S-compartment<br />

is used as “freezer”:<br />

S-damper is open when<br />

compressor is turned on,<br />

S-damper is closed when<br />

compressor is turned off.<br />

•When S-compartment is<br />

used other than “freezer”:<br />

S-damper remains open<br />

for the first 3 minutes and<br />

then closed for the rest<br />

of time.<br />

S-compartment: Versa<br />

(select) compartment.<br />

•When R-damper is open,<br />

V-heater is turned on.<br />

•When R-damper is<br />

closed,<br />

V-heater is turned off.<br />

•When ice making compartment<br />

is used as “refrigerator”,<br />

synchronize I-damper<br />

with R-damper.<br />

•When ice making compartment<br />

is used as “ice making”,<br />

synchronize I-damper<br />

with F-damper.<br />

Compressor is activated<br />

at “Speed-level 2.”<br />

The defrost heater is<br />

stopped and if the next<br />

defrosting finishes in 2<br />

hours, the error code will<br />

disappear .<br />

•3 minutes later, the refrigerator<br />

fan motor is reactivated<br />

to be checked.<br />

•Until the fan motor gets<br />

to operate correctly, the<br />

buzzer sounds every<br />

time the door is closed.<br />

•3 minutes later, the<br />

machine chamber fan<br />

motor is reactivated to be<br />

checked.<br />

•Until the fan motor gets<br />

to operate correctly, the<br />

buzzer sounds every<br />

time the door is closed.<br />

Repair the 100 minutes later, the<br />

contact failure. gear box is reactivated to<br />

be checked again.<br />

2. Ice gear box frozen point Replace<br />

SOFT FZR CRL STOP 3. Check the trouble of the ice gear box<br />

with the ice making test operation.<br />

Replace<br />

Clogging of<br />

Check the compressor and the pipe. When cooling operation<br />

QCK<br />

refrigerant<br />

pipe or trou-<br />

returns to normal condition,<br />

the display of error<br />

ble related to<br />

compressor<br />

code disappears.<br />

SOFT FZR<br />

CHIL<br />

Trouble of<br />

solenoid<br />

three-way<br />

STOP<br />

valve<br />

When defrost thermistor Connector CN9D on control board<br />

reads -10 or above in five 5-pin connector in machine chamber<br />

minutes after the compressor’s<br />

startup. (*5)<br />

Repair the<br />

contact failure.<br />

Check the operation of<br />

solenoid three-way valve<br />

and then open the valve.

Display Error Display<br />

code Tens' place Ones' place<br />

Trouble<br />

Detecting method<br />

(*3)<br />

E 50<br />

CHIL<br />

FZR<br />

Trouble of •When there is any trou-<br />

inverter circuit ble in the circuit which<br />

detects current of com-<br />

(*6) pressor.<br />

E 51<br />

CHIL<br />

FZR<br />

Trouble of •When the range of bus-bar<br />

bus- bar volt- voltage is not approx.<br />

age<br />

DC 50~380 V.<br />

STOP<br />

(*6)<br />

Self-check<br />

Error display<br />

E 52<br />

E 53<br />

E 54<br />

E 55<br />

E 56<br />

E 57<br />

*1 : The setting of ice making compartment will be displayed and blinks during or after ice making test operation.<br />

*2 : This operation is called the recovery operation:<br />

If the damper has not operated ever once during the compressor operation, make the damper operate when the compressor stops.<br />

*3 : When the resistance is , the circuit is deemed open-circuitted.<br />

When the resistance is 0 , the circuit is deemed short-circuited.<br />

*4 : Once E01 is detected, other errors would be ignored and not displayed on the panel.<br />

*5 : Characteristic value may change in order to improve the product.<br />

*6 : The error codes E50 to E55 are not displayed even if those abnormalities occur at power input.<br />

Therefore, be sure to perform ice making test operation in order to check if any abnormality indicated by these error codes occurs. (See page 21.)<br />

*7 : If those errors still continue for 1 minute after the restart, E56 will be displayed again.<br />

24<br />

Check point Treatment Control<br />

CHIL<br />

Trouble of •When the inverter driv-<br />

inverter software ing software malfunc-<br />

FZR CRL<br />

reset function<br />

(*6)<br />

tions.<br />

Refer to “Compressor does not operate” at page 29.<br />

The compressor is suspended<br />

and reactivated<br />

Trouble of •When there is no cur-<br />

10 minutes later.<br />

startup , synrent at compressor star-<br />

CHIL<br />

chronizationtup. or overcurrent •When phase current<br />

detection exceeds 5.5A at com-<br />

(*6) pressor startup.<br />

•When phase current<br />

exceeds 3.3A during com-<br />

FZR CRL STOP<br />

pressor operation.<br />

•When current of 5.3A or<br />

more runs into the busbar<br />

of control board.<br />

CHIL QCK<br />

Trouble of<br />

power supply<br />

When bus-bar voltage 1. Different voltage of power supply outlet<br />

(full wave voltage) is DC<br />

Replace the<br />

control<br />

Refrigerator compartment<br />

room light OFF<br />

FZR<br />

voltage 390V or above in power<br />

board.<br />

input.<br />

2. Trouble of relay in the circuit on the control<br />

(*6)<br />

board<br />

Heaters. OFF<br />

Trouble of EEPROM (IC11M)<br />

Replace the When abnormality occurs in<br />

CHIL QCK control board<br />

(EEPROM<br />

accumulates data necessary<br />

for control.<br />

control<br />

board.<br />

power input, the compressor<br />

is suspended for 10<br />

related trou- •When the data are not<br />

minutes.<br />

ble)<br />

input accurately.<br />

When abnormality occurs in<br />

FZR STOP<br />

•When microcomputer<br />

normal operation, the com-<br />

(*6) cannot read the data.<br />

pressor keeps operating.<br />

Defective wir- The errors E50 to E53<br />

•Error display starts after<br />

ing connecting keep occurring over one<br />

it is regarded as E56.<br />

CHIL QCK or trouble of<br />

control board<br />

and a half hour. (the situation,<br />

which compressor<br />

•Error display continues<br />

until defrosting starts or<br />

cannot be operated, con-<br />

cooling operation gets<br />

tinues.) Refer to “Compressor does not operate” at page 30. back to normal. (Error<br />

display doesn’t disappear<br />

by unplugging and plug-<br />

FZR CRL<br />

ging the power cord. *7)<br />

•Try to restart compressor<br />

every 3 minutes.<br />

Inverter drive When the excess current<br />

Replace the Try to start the compres-<br />

CHIL QCK<br />

module abnor- error is detected before<br />

mality starting the compressor<br />

(failure of the IC in the<br />

inverter drive module).<br />

control<br />

board.<br />

sor every 3 minutes.<br />

FZR CRL STOP

6-3 BLOCK DIAGRAM OF PRINTED CIRCUIT BOARD<br />

<strong>MR</strong>-<strong>G57N</strong>-<strong>NZ</strong><br />

Operation P.C. board<br />

•Setting up temperature, feature, quick mode and eco mode for each<br />

compartment<br />

•Display of self-check<br />

•Outside air thermistor<br />

•Buzzer<br />

6-4 AUTO ICE-MAKER<br />