Structural Floor Panels Design Guide - Hebel Supercrete AAC ...

Structural Floor Panels Design Guide - Hebel Supercrete AAC ...

Structural Floor Panels Design Guide - Hebel Supercrete AAC ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.0 <strong>Design</strong> Considerations<br />

2.1 General <strong>Design</strong> Criteria<br />

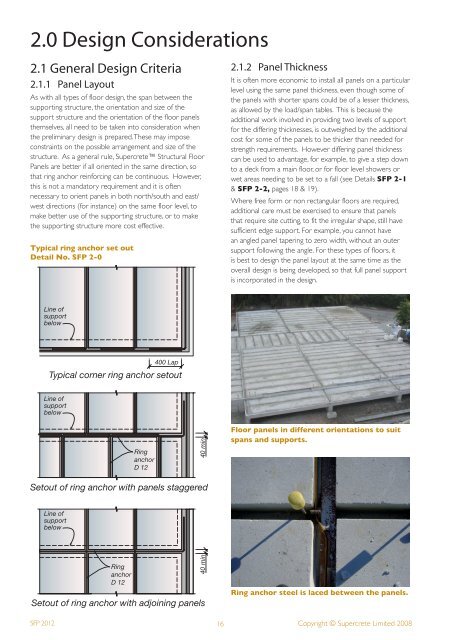

2.1.1 Panel Layout<br />

As with all types of floor design, the span between the<br />

supporting structure, the orientation and size of the<br />

support structure and the orientation of the floor panels<br />

themselves, all need to be taken into consideration when<br />

the preliminary design is prepared. These may impose<br />

constraints on the possible arrangement and size of the<br />

structure. As a general rule, <strong>Supercrete</strong> <strong>Structural</strong> <strong>Floor</strong><br />

<strong>Panels</strong> are better if all oriented in the same direction, so<br />

that ring anchor reinforcing can be continuous. However,<br />

this is not a mandatory requirement and it is often<br />

necessary to orient panels in both north/south and east/<br />

west directions (for instance) on the same floor level, to<br />

make better use of the supporting structure, or to make<br />

the supporting structure more cost effective.<br />

Typical ring anchor set out<br />

Detail No. SFP 2-0<br />

Line of<br />

support<br />

below<br />

Typical corner ring anchor setout<br />

Line of<br />

support<br />

below<br />

Setout of ring anchor with panels staggered<br />

Line of<br />

support<br />

below<br />

Ring<br />

anchor<br />

D 12<br />

Ring<br />

anchor<br />

D 12<br />

400 Lap<br />

Setout of ring anchor with adjoining panels<br />

40 min<br />

40 min<br />

2.1.2 Panel Thickness<br />

It is often more economic to install all panels on a particular<br />

level using the same panel thickness, even though some of<br />

the panels with shorter spans could be of a lesser thickness,<br />

as allowed by the load/span tables. This is because the<br />

additional work involved in providing two levels of support<br />

for the differing thicknesses, is outweighed by the additional<br />

cost for some of the panels to be thicker than needed for<br />

strength requirements. However differing panel thickness<br />

can be used to advantage, for example, to give a step down<br />

to a deck from a main floor, or for floor level showers or<br />

wet areas needing to be set to a fall (see Details SFP 2-1<br />

& SFP 2-2, pages 18 & 19).<br />

Where free form or non rectangular floors are required,<br />

additional care must be exercised to ensure that panels<br />

that require site cutting, to fit the irregular shape, still have<br />

sufficient edge support. For example, you cannot have<br />

an angled panel tapering to zero width, without an outer<br />

support following the angle. For these types of floors, it<br />

is best to design the panel layout at the same time as the<br />

overall design is being developed, so that full panel support<br />

is incorporated in the design.<br />

<strong>Floor</strong> panels in different orientations to suit<br />

spans and supports.<br />

Ring anchor steel is laced between the panels.<br />

SFP 2012 16 Copyright © <strong>Supercrete</strong> Limited 2008