SWISSFLOAT Operating manual E KRESS - Eisenhut-Vet AG

SWISSFLOAT Operating manual E KRESS - Eisenhut-Vet AG

SWISSFLOAT Operating manual E KRESS - Eisenhut-Vet AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2010-03-17<br />

Dok-ID: EV-0708-F3<br />

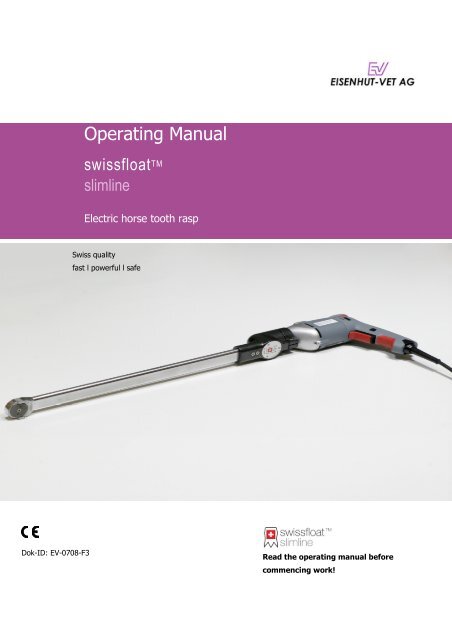

<strong>Operating</strong> Manual<br />

swissfloat TM<br />

slimline<br />

Electric horse tooth rasp<br />

Swiss quality<br />

fast l powerful l safe<br />

Read the operating <strong>manual</strong> before<br />

commencing work!

© EISENHUT-VET <strong>AG</strong><br />

<strong>Vet</strong>erinarian instruments<br />

Sandweg 52<br />

CH-4123 Allschwil<br />

Tel.: +41 (0) 61 307 9000<br />

Fax: +41 (0) 61 307 9009<br />

E-mail: info@eisenhut-vet.ch<br />

Web: www.eisenhut-vet.ch<br />

swissfloat TM slimline is a registered trademark<br />

of EISENHUT-VET <strong>AG</strong><br />

Created by:<br />

Kothes! Schweiz GmbH<br />

www.kothes.ch<br />

2 2010-03-17

Electric horse tooth rasp<br />

Contents<br />

1 General information......................................................6<br />

1.1 Information about this operating <strong>manual</strong> .................... 6<br />

1.2 Explanation of symbols .............................................. 7<br />

1.3 Limitation of liability .................................................. 8<br />

1.4 Copyright.................................................................. 8<br />

1.5 Spare parts ............................................................... 9<br />

1.6 Customer service....................................................... 9<br />

2 Safety..........................................................................10<br />

2.1 Responsibilities of the user....................................... 10<br />

2.2 Personnel requirements ........................................... 11<br />

2.3 Intended use........................................................... 12<br />

2.4 Personal protective equipment ................................. 13<br />

2.5 Particular dangers ................................................... 14<br />

2.6 Environmental protection ......................................... 16<br />

3 Technical Specifications .............................................17<br />

3.1 General information................................................. 17<br />

3.2 Connected loads...................................................... 18<br />

3.3 Emissions................................................................ 18<br />

3.4 Nameplate .............................................................. 19<br />

4 Setup and function .....................................................20<br />

4.1 Entire machine ........................................................ 20<br />

4.2 Description of components....................................... 21<br />

4.2.1 Rasping head............................................ 21<br />

4.2.2 Power unit ................................................ 21<br />

4.2.3 Fitting....................................................... 22<br />

4.2.4 Residual current circuit breaker.................. 22<br />

5 Transport, packaging, and storage.............................23<br />

5.1 Transport inspection................................................ 23<br />

5.2 Packaging ............................................................... 23<br />

5.3 Storage................................................................... 24<br />

2010-03-17 3

Electric horse tooth rasp<br />

Contents<br />

6 Use ..............................................................................25<br />

6.1 Safety .....................................................................25<br />

6.2 Initial operation .......................................................26<br />

6.2.1 Mounting the rasping disk ..........................26<br />

6.2.2 Marking the residual current circuit breaker.27<br />

6.3 Activities prior to use ...............................................28<br />

6.3.1 Function check residual current circuit<br />

breaker .....................................................28<br />

6.4 <strong>Operating</strong> the machine.............................................29<br />

6.4.1 Switching the machine on ..........................29<br />

6.4.2 Locking rotating speed...............................29<br />

6.4.3 Switching the machine off ..........................30<br />

6.5 Dental treatment .....................................................31<br />

6.5.1 Safety .......................................................31<br />

6.5.2 Dental treatment .......................................32<br />

6.5.2.1 Lower jaw ...................................33<br />

6.5.2.2 Upper jaw ...................................33<br />

6.5.2.3 Hook at lower jaw .......................33<br />

6.5.2.4 Hook at upper jaw.......................34<br />

6.5.2.5 Incisors and canines ....................35<br />

6.5.2.6 Chewing surface..........................35<br />

6.6 Activities after use ...................................................36<br />

6.6.1 Cleaning after every use ............................36<br />

6.6.2 Cleaning as needed ...................................37<br />

6.7 Working on the machine ..........................................38<br />

6.7.1 Aligning the rasp attachment......................38<br />

6.7.2 Changing the rasping disk ..........................39<br />

7 Troubleshooting........................................................411<br />

7.1 Safety ................................................................... 411<br />

7.2 Troubleshooting table ............................................ 422<br />

7.3 Troubleshooting steps ............................................ 433<br />

7.3.1 Adjusting the belt tension (only when cold)433<br />

7.3.2 Changing the sealing ring......................... 444<br />

7.4 Use after fault has been corrected .......................... 455<br />

8 Disposal ....................................................................466<br />

9 Spare parts ...............................................................477<br />

9.1 Spare part orders................................................... 477<br />

9.2 Spare parts list ...................................................... 477<br />

4 2010-03-17

Electric horse tooth rasp<br />

Contents<br />

10 Appendix.....................................................................50<br />

10.1 Declaration of Conformity .......................... 50<br />

11 Index ..........................................................................51<br />

2010-03-17 5

Electric horse tooth rasp<br />

General information<br />

1 General information<br />

1.1 Information about this operating <strong>manual</strong><br />

This operating <strong>manual</strong> allows you to use the machine in a safe and<br />

efficient manner.<br />

Read this <strong>manual</strong> carefully before commencing work.<br />

It is essential for the safe operation of the machine that you follow<br />

all safety and operating instructions provided herein.<br />

Store this operating <strong>manual</strong> in a safe location. Include this<br />

operating <strong>manual</strong> if you pass the machine on to third parties.<br />

6 2010-03-17

1.2 Explanation of symbols<br />

Electric horse tooth rasp<br />

General information<br />

Safety instructions The safety instructions provided in this <strong>manual</strong> are marked by<br />

symbols. The safety instructions are preceded by signal word<br />

pointing out the extent of danger.<br />

Make sure to carefully observe the safety instructions to prevent<br />

accident as well as personal injury and property damage.<br />

DANGER!<br />

… indicates a hazardous situation which, if not<br />

avoided, will result in death or serious injury.<br />

WARNING!<br />

… indicates a hazardous situation which, if not<br />

avoided could result in death or serious injury.<br />

CAUTION!<br />

… indicates a hazardous situation which, if not<br />

avoided, could result in minor or moderate injury.<br />

NOTICE!<br />

… indicates a potentially hazardous situation which,<br />

if not avoided, may result in property damage.<br />

Special safety instructions To draw your attention to special dangers, this <strong>manual</strong> uses the<br />

following symbols in safety instructions:<br />

Tips and recommendations<br />

… identifies dangers caused by electric current.<br />

Failure to observe these safety instructions may<br />

cause serious injury or death.<br />

IMPORTANT!<br />

… points out useful tips and recommendations as<br />

well as information intended to guarantee efficient<br />

and trouble-free operation.<br />

2010-03-17 7

Electric horse tooth rasp<br />

General information<br />

1.3 Limitation of liability<br />

1.4 Copyright<br />

All information and instructions provided in this <strong>manual</strong> has been<br />

composed in compliance with all applicable standards and<br />

regulations, the state of the art as well as based on our long years<br />

of expertise and experience.<br />

The manufacturer will not assume any liability for damages caused<br />

by:<br />

� Failure to observe this <strong>manual</strong><br />

� Improper use<br />

� Use of unqualified personnel<br />

� Unauthorized retrofitting<br />

� Technical modifications<br />

� Use of unapproved spare parts<br />

The actually included components may vary from the explanations<br />

and illustrations herein for special models and custom orders or<br />

due to the latest technical modifications.<br />

The obligations agreed upon in the supply contract, the Terms and<br />

Conditions, the manufacturer's terms of delivery as well as the<br />

legal requirements applicable at the time of conclusion shall apply.<br />

We reserve the right to introduce technical modifications to<br />

improve the usability of the machine and develop it further.<br />

This <strong>manual</strong> is protected by copyright and intended for in-house<br />

purposes only.<br />

Passing this <strong>manual</strong> on to third parties, duplications of any kind -<br />

even in excerpts - or using and/or disclosing the content of the<br />

<strong>manual</strong> without the prior written of the manufacturer is prohibited<br />

except for in-house purposes. Any violations shall result in liability<br />

for damages. Further claims shall remain reserved.<br />

8 2010-03-17

1.5 Spare parts<br />

1.6 Customer service<br />

Electric horse tooth rasp<br />

General information<br />

WARNING!<br />

Safety risk due to incorrect spare parts!<br />

Incorrect or defective spare parts may affect safety<br />

and cause damage, malfunctions or total loss.<br />

Therefore:<br />

– Use only original spare parts made by the<br />

manufacturer.<br />

– Different spare parts may not be used without<br />

consulting the manufacturer in writing.<br />

Purchase spare parts from your authorized dealer or directly from<br />

the manufacturer. For address, see page 2.<br />

The spare parts list is included in the appendix.<br />

Our customer service will assist you with any technical questions<br />

you may have. For contact information, see page 2.<br />

Moreover, our employees are always interested in gaining new<br />

information and experience resulting from the use of our products<br />

which may help improve their quality.<br />

2010-03-17 9

Electric horse tooth rasp<br />

Safety<br />

2 Safety<br />

2.1 Responsibilities of the user<br />

This section provides an overview of all important safety aspects<br />

necessary to keep man and animal perfectly safe and provide for<br />

the safe and trouble-free operation of the machine.<br />

Failure to observe the instructions and safety information provided<br />

in this <strong>manual</strong> may lead to serious danger.<br />

This machine is intended to be used as veterinarian equipment.<br />

The person using the machine is, therefore, obligated to observe<br />

all legal requirements with regard to occupational safety.<br />

In addition to following the safety instructions provided in this<br />

<strong>manual</strong>, the user is also obligated to comply with all safety,<br />

accident prevention as well as animal and environmental<br />

protection regulations applicable for the application area of the<br />

machine. In particular, the user:<br />

� must become familiar with the applicable occupational health<br />

and safety regulations.<br />

� must ensure that all employees handling the machine have<br />

read and understood this <strong>manual</strong>.<br />

� must provide the necessary protective equipment.<br />

� must check all safety installations regularly for proper<br />

operation and completeness.<br />

� is responsible for keeping the machine in proper technical<br />

condition at all times.<br />

10 2010-03-17

2.2 Personnel requirements<br />

Qualifications<br />

WARNING!<br />

Risk of injury due to insufficient<br />

qualification!<br />

Electric horse tooth rasp<br />

Safety<br />

Improper use may lead to serious injury to man<br />

and animal as well as property damage.<br />

Therefore:<br />

– have all activities performed by qualified<br />

personnel only.<br />

This operating <strong>manual</strong> specified the following qualifications as<br />

required for different range of activity:<br />

� Qualified personnel<br />

are capable of performing the tasks assigned to them in a safe<br />

manner thanks to their expert training, skills and experience.<br />

Qualified personnel are capable of independently detecting,<br />

assessing and avoiding risks to themselves and the animal.<br />

Qualified personnel are familiar with the content of all<br />

applicable regulations, guidelines, and standards required by<br />

law for the safe use of the machine and are capable of<br />

implementing the specified requirements.<br />

Qualified personnel have the expert skills required for the<br />

machine's range of application and comply with all hygiene<br />

regulations applicable to the use of veterinary equipment.<br />

� Trained electrician<br />

is capable of performing work on electrical systems and<br />

independently detecting and avoiding any possible risks thanks<br />

to his or her expert training, skills and experience as well as his<br />

or her knowledge of all applicable standards and regulations.<br />

Trained electricians are trained to work in the specific location<br />

to which they are assigned and know all relevant standards and<br />

regulations.<br />

2010-03-17 11

Electric horse tooth rasp<br />

Safety<br />

2.3 Intended use<br />

The machine has been designed and constructed exclusively for<br />

the intended purpose described herein.<br />

� The machine may only be used for veterinary applications.<br />

� The machine may only be used specifically treat the teeth of<br />

horses and other equids.<br />

Intended use also includes compliance with all instructions<br />

provided in this <strong>manual</strong>.<br />

Any use exceeding or deviating from the intended use of the<br />

machine is considered improper and may lead to dangerous<br />

situations.<br />

WARNING!<br />

Risk due to improper use!<br />

Improper use of the machine may lead to<br />

dangerous situations.<br />

In particular, refrain from using the machine for<br />

the following purposes:<br />

– Use of the machine in human medicine.<br />

– Use of the machine as a grinding machine<br />

beyond the scope of veterinary medicine.<br />

Claims of any kind for damages caused by improper use shall be<br />

excluded.<br />

12 2010-03-17

2.4 Personal protective equipment<br />

Electric horse tooth rasp<br />

Safety<br />

Working with the machine requires that you wear personal<br />

protective equipment to minimize risks to the health of man and<br />

animal.<br />

Always wear the required protective equipment when working with<br />

the machine.<br />

Always wear When working with the machine, always wear:<br />

Suitable work clothes<br />

is clothing suitable for the activities performed in the work<br />

environment as well as the weather conditions.<br />

Refrain from wearing rings, chains or jewelry.<br />

Non-slip shoes<br />

provide protection from slipping.<br />

Wear for specific tasks Special protective equipment is required when performing specific<br />

tasks. Wear this equipment as required for the performance of<br />

these tasks. The following is an explanation of this special<br />

protective equipment:<br />

Hearing protection<br />

provide protection from hearing damage.<br />

Safety goggles<br />

protect the eyes from flying parts and splashes of liquid.<br />

Gloves protecting against microorganisms<br />

provided protection against microbiological hazards caused by<br />

viruses or bacteria.<br />

Check protective gloves for tightness before using them. Clean<br />

gloves before taking them off and store them in a well ventilated<br />

area.<br />

2010-03-17 13

Electric horse tooth rasp<br />

Safety<br />

2.5 Particular dangers<br />

Electric current<br />

Noise<br />

The following section specifies residual risks ascertained by means<br />

of a risk assessment.<br />

� The safety instructions herein and the warnings specified in the<br />

further chapters of this <strong>manual</strong> must be observed to reduce the<br />

risk of health hazards and dangerous situations.<br />

DANGER!<br />

Danger of death due to electric current!<br />

There is danger of death when coming into contact<br />

with live components. Damage to the insulation or<br />

individual components may lead to death.<br />

Therefore:<br />

– In the event of damage to the insulation,<br />

switch off the power supply immediately and<br />

initiate repairs.<br />

– Do not operate the machine without a residual<br />

current circuit breaker.<br />

– Check if the residual current circuit breaker<br />

functions properly before using the machine.<br />

– When disconnecting the residual current circuit<br />

breaker from the power socket, always use so<br />

by pulling on the plug but never on the cord.<br />

– Before connecting the machine to the power<br />

supply, compare the information provided in<br />

the Technical Specifications with the<br />

specifications of the mains supply.<br />

– Work on the electrical system may only be<br />

performed by trained electricians.<br />

WARNING!<br />

Hearing damage caused by noise!<br />

The noise level generated in the work area may<br />

cause hearing damage.<br />

Therefore:<br />

– Always wear hearing protection when working<br />

with the machine.<br />

14 2010-03-17

Rotating rasping disk<br />

Hot surfaces<br />

Electric horse tooth rasp<br />

Safety<br />

CAUTION!<br />

Risk of injury due to rotating rasping disks!<br />

Rotating rasping disks may cause injury by friction<br />

or abrasion.<br />

Therefore:<br />

– Do not reach into the rotating rasping disk while<br />

using the machine.<br />

– Avoid bodily contact and prevent third parties<br />

from coming into contact with the rotating<br />

rasping disk.<br />

CAUTION!<br />

Risk of sustaining burns on hot surfaces!<br />

Depending on the intensity of the pressure exerted<br />

on the rasping head and the duration of the<br />

grinding, the rasping head may become hot.<br />

Coming into contact with hot components may lead<br />

to burns.<br />

Therefore:<br />

– Stop grinding at regular intervals and cool the<br />

rasping head by immersing it briefly in water.<br />

– After use, do not touch the rasping head with<br />

your bare hands until after you have briefly<br />

immersed it in water.<br />

2010-03-17 15

Electric horse tooth rasp<br />

Safety<br />

2.6 Environmental protection<br />

Damage to the environment<br />

NOTICE!<br />

Environmental hazard due to improper<br />

handling!<br />

If environmentally hazardous substances are<br />

handled improperly (particularly, if these<br />

substances are disposed of in an unsuitable<br />

manner), damage may be caused to the<br />

environment.<br />

Therefore:<br />

– Always observe the information provided below.<br />

– Take immediate steps if environmentally<br />

hazardous substances are leaked into the<br />

environment by accident. If in doubt, notify the<br />

responsible local authorities about the damage<br />

immediately.<br />

The following environmentally hazardous substances are used:<br />

Lubricants Lubricants such as greases and oils contain toxic substances. They<br />

must not be introduced into the environment. They must be<br />

disposed of by a specialized waste management company.<br />

16 2010-03-17

3 Technical Specifications<br />

3.1 General information<br />

Tooth rasp "swissfloat TM slimline"<br />

Tooth rasp pony "swissfloat TM<br />

slimline"<br />

Specification without power<br />

drill<br />

Electric horse tooth rasp<br />

Technical Specifications<br />

Value Unit<br />

Length 65.0 cm<br />

Width 5.5 cm<br />

Height 6.2 cm<br />

Specification with power drill Value Unit<br />

Length 84.5 cm<br />

Width 6.5 cm<br />

Height 25.0 cm<br />

Specification without power<br />

drill<br />

Value Unit<br />

Length 53.7 cm<br />

Width 5.5 cm<br />

Height 6.2 cm<br />

Specification with power drill Value Unit<br />

Length 73.2 cm<br />

Width 6.5 cm<br />

Height 25.0 cm<br />

2010-03-17 17

Electric horse tooth rasp<br />

Technical Specifications<br />

Tooth rasp short "swissfloat TM<br />

slimline"<br />

3.2 Connected loads<br />

Electrical<br />

3.3 Emissions<br />

Specification without power<br />

drill<br />

Value Unit<br />

Length 30.2 cm<br />

Width 6.5 cm<br />

Height 6.2 cm<br />

Specification with power drill Value Unit<br />

Length 49.7 cm<br />

Width 6.5 cm<br />

Height 25.0 cm<br />

Specification Value Unit<br />

Rated voltage 230 V<br />

Rated current 10 A<br />

Power consumption, maximum 650 W<br />

Power output 220 W<br />

Specification Value Unit<br />

Noise emission machine 81 dB(A)<br />

The machine's sound pressure level may exceed 84 dB(A)<br />

depending on the task performed.<br />

18 2010-03-17

3.4 Nameplate<br />

Fig. 1<br />

Fig. 2<br />

1<br />

Electric horse tooth rasp<br />

Technical Specifications<br />

The nameplate is located above the cover of the fitting (1).<br />

It contains the following information:<br />

1 Serial number<br />

2 Manufacturer<br />

3 CE mark<br />

4 Web address<br />

2010-03-17 19

Electric horse tooth rasp<br />

Setup and function<br />

4 Setup and function<br />

4.1 Entire machine<br />

Overview<br />

Fig. 3<br />

1<br />

1 Rasping head<br />

2 Tube<br />

3 Residual current circuit breaker<br />

4 Cord<br />

5 Housing<br />

6 Power unit<br />

7 Controls power unit<br />

Brief description The machine is an electric tooth rasp used for treating tooth<br />

irregularities in horses and other equids by means of a rotating<br />

rasping disk. The machine is powered by a fully safety insulated<br />

single-gear power drill. To prevent fault currents, the machine is<br />

equipped with a residual current circuit breaker.<br />

20 2010-03-17<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7

4.2 Description of components<br />

4.2.1 Rasping head<br />

Overview<br />

Fig. 4<br />

1 Rasping disk<br />

2 M5x8 countersunk screw<br />

3 Side flange<br />

4 Rasping head and tube<br />

Electric horse tooth rasp<br />

Setup and function<br />

Brief description Depending on the application as well as the experience of the<br />

operator, the rasping head is used to mount diamond-coated<br />

rasping disks or rasping disks made of hard metal. The side<br />

flanges are used to protect the mucous membrane of the animal<br />

and allow the operator to guide the rasping head along the row of<br />

teeth.<br />

4.2.2 Power unit<br />

Overview<br />

Fig. 5<br />

1<br />

2<br />

3<br />

1 Nameplate power unit<br />

2 ON/OFF button<br />

3 Lock button<br />

Brief description The machine is powered by a fully safety insulated single-gear<br />

power drill made by <strong>KRESS</strong>. The operator can use the ON/OFF<br />

button to infinitely adjust the speed of the power unit. The lock<br />

button makes it possible to lock the power unit at the highest<br />

speed.<br />

2010-03-17 21

Electric horse tooth rasp<br />

Setup and function<br />

4.2.3 Fitting<br />

Overview<br />

Fig. 6<br />

1 Two countersunk screws (M5x16)<br />

2 Three countersunk slotted screws (1x M3x12, 2x M3x40)<br />

3 Cover (with nameplate)<br />

4 Housing<br />

5 Fillister head screw (M5x16)<br />

Brief description The fitting is the interface between the power unit and the rasp<br />

attachment. A square bolt is used to insert the power unit into the<br />

receiver of the housing and secured by with fillister head screw<br />

(5). Loosening the fillister head screw makes it possible to rotate<br />

the fitting by 180° and align the rasp attachment. The belt tension<br />

is retained by two countersunk screws (1).<br />

4.2.4 Residual current circuit breaker<br />

Overview<br />

Fig. 7<br />

1 2 3 4 5<br />

1 Control lamp<br />

2 RESET button<br />

3 TEST button<br />

4 Power plug<br />

5 Nameplate residual current circuit breaker<br />

6 Cord<br />

Brief description The electronic residual current circuit breaker will cut off the<br />

current circuit from the rest of the mains if the current exceeds the<br />

amperage difference of 30 mA.<br />

22 2010-03-17

5 Transport, packaging, and storage<br />

5.2 Transport inspection<br />

5.3 Packaging<br />

About the packaging<br />

Fig. 8<br />

Electric horse tooth rasp<br />

Transport, packaging, and storage<br />

Check the shipment for completeness and transport damage<br />

immediately upon receiving it.<br />

In case of visible transport damage, proceed as follows:<br />

� Do not accept the shipment or accept it under protest.<br />

� Record the extent of the damage on the transport documents<br />

or the delivery note of the carrier.<br />

� Initiate a complaint.<br />

IMPORTANT!<br />

File a complaint immediately upon detecting the<br />

corresponding defect. Claims for damages can only<br />

be accepted if filed within the statutory deadlines<br />

for making a complaint.<br />

The machine has been packaged in a carrying bag and a covering<br />

box according to the expected transport and storage conditions.<br />

The packaging is made up exclusively of environmentally friendly<br />

materials.<br />

The packaging is intended to protect the machine from transport<br />

damage, corrosion and other kinds of damage. Therefore, store<br />

the machine in its carrying bag when not in use.<br />

2010-03-17 23

Electric horse tooth rasp<br />

Transport, packaging, and storage<br />

Handling packaging materials Dispose of packaging material in compliance with all applicable<br />

statutory and local regulations.<br />

5.4 Storage<br />

NOTICE!<br />

Damage to the environment due to incorrect<br />

disposal!<br />

Packaging materials are valuable resources and<br />

are, in many cases, suitable for continued use,<br />

reuse or recycling.<br />

Therefore:<br />

– Dispose of packaging materials in an<br />

environmentally safe manner.<br />

– Observe the local waste disposal regulations.<br />

Storing the machine Store the machine under the following conditions:<br />

� Store the machine in its carrying bag.<br />

� Store in a dry and dust-free environment.<br />

� Do not expose the machine to abrasive media.<br />

� Protect the machine from exposure to the sun.<br />

� Avoid mechanical vibrations.<br />

24 2010-03-17

6 Use<br />

6.1 Safety<br />

Electric horse tooth rasp<br />

Personal protective equipment Use the following protective equipment whenever you work with<br />

the machine:<br />

Improper use<br />

� suitable work cloths<br />

� non-slip shoes<br />

WARNING!<br />

Risk of injury due to improper use!<br />

Improper use may lead to serious injury or<br />

property damage.<br />

Therefore:<br />

– Follow all operating steps as specified by the<br />

instructions in this operating <strong>manual</strong>.<br />

– Before commencing work, make sure the<br />

residual current circuit breaker functions<br />

properly.<br />

2010-03-17 25<br />

Use<br />

– Keep the work area tidy and clean! Components<br />

and tools lying loosely about or on top of each<br />

other may cause accidents.

Electric horse tooth rasp<br />

Use<br />

6.2 Initial operation<br />

6.2.1 Mounting the rasping disk<br />

Fig. 9<br />

Fig. 10<br />

Fig. 11<br />

Depending on the machine's type of delivery, you will have to<br />

mount the rasping disk on the rasping head before you can use<br />

the machine for the first time:<br />

1. Remove the protective film from the rasping head.<br />

2. Unscrew the pre-installed M5x8 countersunk screw (1) from<br />

the bore.<br />

3. Align the driving pins (1) of the rasping head with the bores<br />

(2) on the rasping disk.<br />

4. Place the rasping disk onto the rasping head.<br />

5. Make sure that both driving pins are inside the bores of the<br />

rasping disk. If necessary, slightly turn the rasping disk until<br />

the driving pins lock into place.<br />

26 2010-03-17

Fig. 12<br />

Fig. 13<br />

Electric horse tooth rasp<br />

6. Insert the M5x8 countersunk screw into the bore on the<br />

rasping disk.<br />

7. Place the fixing plate (1) onto the rasping disk.<br />

2010-03-17 27<br />

Use<br />

8. Make sure that the fixing pins (2) of the fixing plate are inside<br />

the fixing holes (3) on the rasping disk. If necessary, turn the<br />

rasping disk slightly until the fixing pins lock into place.<br />

9. Use one finger to press and hold the fixing plate on the<br />

rasping disk.<br />

10. Tighten the M5x8 countersunk screw using a Torx 25<br />

screwdriver (1).<br />

6.2.2 Marking the residual current circuit breaker<br />

Fig. 14<br />

The residual current circuit breaker must be inserted vertically into<br />

the power socket. Marked on the nameplate of the residual current<br />

circuit breaker are the "top" and "bottom" positions. If necessary,<br />

you must stick the included labels in the language of your country<br />

over these markings.<br />

1. Check if the markings (1) are in the language of your country.<br />

2. Stick the new labels over the markings if necessary.<br />

3. Make sure the specified arrow directions are retained.

Electric horse tooth rasp<br />

Use<br />

6.3 Activities prior to use<br />

6.3.1 Function check residual current circuit breaker<br />

Fig. 15<br />

Fig. 16<br />

DANGER!<br />

Risk of injury due to electric current!<br />

If the residual current circuit breaker is not fully<br />

operational or used incorrectly, components may<br />

become live due to malfunctions. Coming into<br />

contact with live components may cause injury.<br />

Therefore:<br />

– Do not operate the machine without a residual<br />

current circuit breaker.<br />

– Check if the residual current circuit breaker<br />

functions properly prior to every use.<br />

– Never operate the machine unless the residual<br />

current circuit breaker is fully functional.<br />

Proceed as follows to test the operability of the residual current<br />

circuit breaker before using the machine:<br />

1. Insert the residual current circuit breaker vertically into the<br />

power socket.<br />

2. Press the RESET button (1) on the residual current circuit<br />

breaker.<br />

The residual current circuit breaker is not operational unless<br />

� the control lamp (2) lights up red.<br />

3. Press the TEST button (1) on the residual current circuit<br />

breaker.<br />

The residual current circuit breaker is not operational unless<br />

� the control lamp (2) goes out and<br />

� a distinct switching noise can be heard.<br />

After the function test was completed successfully:<br />

4. Press the RESET button.<br />

The residual current circuit breaker is operational.<br />

28 2010-03-17

6.4 <strong>Operating</strong> the machine<br />

6.4.1 Switching the machine on<br />

Fig. 17<br />

Fig. 18<br />

6.4.2 Locking rotating speed<br />

Fig. 19<br />

1<br />

1<br />

2<br />

Electric horse tooth rasp<br />

1. Insert the residual current circuit breaker vertically into the<br />

power socket.<br />

2. Press the RESET button (1) on the residual current circuit<br />

breaker.<br />

2010-03-17 29<br />

Use<br />

The control lamp (2) on the residual current circuit breaker lights<br />

up red. The residual current circuit breaker is switched on.<br />

3. Press the ON/OFF button (1) of the power unit.<br />

Depending on how you press the ON/OFF button (1), the machine<br />

will start up at variable speed:<br />

� Slight pressure: low speed, allows the machine to start up<br />

smoothly and in a controlled manner<br />

� Great pressure (up to the stop position): high speed, machine<br />

starts up quickly.<br />

To save you the trouble of pressing and holding the ON/OFF<br />

button during operation, you can lock the machine at the<br />

maximum rotating speed:<br />

1. Press the ON/OFF button (1) until you reach the stop and<br />

hold it.<br />

2. Press and hold the lock button (2).<br />

3. Release the ON/OFF button (1).<br />

The lock button (2) engages.<br />

4. Release the lock button (2).

Electric horse tooth rasp<br />

Use<br />

6.4.3 Switching the machine off<br />

Fig. 20<br />

1<br />

2<br />

If the ON/OFF button (1) is pressed:<br />

1. Release the ON/OFF button (1).<br />

If the rotating speed is locked:<br />

1. Press the ON/OFF button (1) until the lock button (2)<br />

disengages.<br />

2. Release the ON/OFF button (1).<br />

30 2010-03-17

Dental treatment<br />

6.5 Dental treatment<br />

6.5.1 Safety<br />

Electric horse tooth rasp<br />

Personal protective equipment Wear the following protective equipment while performing the<br />

dental treatment:<br />

Full mouth speculum<br />

Risk of injury to third parties<br />

� Hearing protection<br />

� Non-slip shoes<br />

2010-03-17 31<br />

Use<br />

It is at the discretion of the qualified personnel if the following<br />

protective equipment must be worn during the dental treatment:<br />

� Safety goggles<br />

� Protective gloves<br />

WARNING!<br />

Risk of injury if no full mouth speculum is<br />

used!<br />

Unless a full mouth speculum is used, there is a<br />

risk of injury to the operator and the animal during<br />

the dental treatment.<br />

Therefore:<br />

– Do not use the machine for dental treatments<br />

without a full mouth speculum.<br />

CAUTION!<br />

Risk of injuries to third parties standing in<br />

the work area!<br />

If the machine is used in a careless manner, third<br />

parties standing in the work area may become<br />

injured.<br />

Therefore:<br />

– Be aware of the machine's dimensions and<br />

weight while using the machine.<br />

– Pay attention to third parties in the work area<br />

when moving around with the machine.

Electric horse tooth rasp<br />

Use<br />

Risk of infection<br />

Overheating<br />

6.5.2 Dental treatment<br />

Bleeding<br />

T<br />

NOTICE!<br />

Risk of infection!<br />

The gums of the animal may become hurt during<br />

the dental treatment. As a consequence, bacteria<br />

may enter the wound and cause infections.<br />

Therefore:<br />

– Make sure the tetanus vaccination of the animal<br />

is up to date at the time the dental treatment is<br />

performed.<br />

NOTICE!<br />

Danger to the animal's health and risk of<br />

machine damage if the rasping head<br />

overheats!<br />

Depending on the intensity of the pressure exerted<br />

on the rasping head and the duration of the<br />

grinding, the rasping head may become hot. If<br />

overheated, the rasping head may burn the animal<br />

and cause damage to the machine.<br />

Therefore:<br />

– Stop grinding at regular intervals and cool the<br />

rasping head by immersing it briefly in water.<br />

IMPORTANT!<br />

There is no danger to the animal's health if<br />

bleeding of the gums occurs in the course of<br />

normal dental treatment.<br />

Bleeding may occur, in particular, during the<br />

treatment of the teeth in the back of the mouth<br />

(M3) as these teeth are rather close to the gums.<br />

The following is a list of recommended tasks to be performed<br />

during dental treatment. Each dental treatment must be performed<br />

and assessed individually and in accordance with the conditions<br />

present.<br />

32 2010-03-17

6.5.2.1 Lower jaw<br />

6.5.2.2 Upper jaw<br />

6.5.2.3 Hook at lower jaw<br />

The mouth must be opened all the way.<br />

Electric horse tooth rasp<br />

1. When positioning the rasping head at the location to be<br />

ground, align the rasping head parallel to the teeth on the<br />

tongue side.<br />

2010-03-17 33<br />

Use<br />

2. Move the rasping head from the back to the front. While doing<br />

so, rotate the rasping head by 45° across the chewing surface.<br />

1. Position the rasping head between cheek and grinder.<br />

2. Move the rasping head from the front to the back. While doing<br />

so, change the angle of approach by 30° to 60°.<br />

Fig. 21<br />

If there is enough room:<br />

1. Position the rasping head between upper and lower jaw.<br />

2. Grind off the hook at the lower jaw.<br />

If the rasping head cannot be positioned directly between upper<br />

and lower jaw due to the size of the hook:<br />

1. Position the rasping head parallel to the teeth on the tongue<br />

side and proceed to the spot that needs to be treated.<br />

Fig. 22

Electric horse tooth rasp<br />

Use<br />

6.5.2.4 Hook at upper jaw<br />

Hook at 106 and 206 1. Put the rasping head diagonally to the hook and round the<br />

hook from the front by grinding.<br />

Hook at 111 and 211 If there is enough room:<br />

1. Put the rasping head to the hook between upper and lower<br />

jaw.<br />

2. Grind off the hook.<br />

If the rasping head cannot be positioned directly between upper<br />

and lower jaw due to the size of the hook:<br />

1. Position the rasping head on the cheek side and proceed to<br />

the spot that needs to be treated.<br />

2. Make sure the cheek muscle is not tightened to prevent<br />

possible injury.<br />

Fig. 23<br />

34 2010-03-17

6.5.2.5 Incisors and canines<br />

6.5.2.6 Chewing surface<br />

Electric horse tooth rasp<br />

For perfect guidance of the machine during the treatment of<br />

incisors and canines:<br />

2010-03-17 35<br />

Use<br />

1. Place the machine between arm and body or rest it on your<br />

shoulder.<br />

2. Hold the rasping hand with one hand while putting the other<br />

hand to the incisor or canine.<br />

3. Switch the machine on and grind off the tooth exerting slight,<br />

controlled pressure on the ON/OFF button.<br />

Fig. 24<br />

306 and 406 Apply the following method for treating the chewing surface until<br />

you reach the desired result:<br />

1. Put the rasping head to 306 or 406.<br />

2. Push the rasping head down.<br />

To achieve perfect roundness:<br />

1. Put the rasping head diagonally to the teeth and ground them<br />

off on both sides.<br />

2. Make sure not to hurt the dental pulp.<br />

Fig. 25

Electric horse tooth rasp<br />

Use<br />

6.6 Activities after use<br />

After every use<br />

6.6.1 Cleaning after every use<br />

WARNING!<br />

Risk of infection to man and animal in case<br />

of improper cleaning and disinfection!<br />

There is a risk of infection caused by<br />

microorganisms passed on from animal to man and<br />

animal to animal if the machine is not properly<br />

cleaned and disinfected after use.<br />

Therefore:<br />

– Clean and disinfect the machine after each use.<br />

– Wear gloves protecting against microorganisms<br />

while using, cleaning, and disinfecting the<br />

machine.<br />

Clean and disinfect the rasp attachment after each use as<br />

described below:<br />

� use a soft plastic brush<br />

� use standard cleaning agents<br />

� use disinfectants<br />

� Use clear water to rinse cleaning agents and disinfectants off<br />

thoroughly<br />

IMPORTANT!<br />

Also follow the instructions with regard to contact<br />

times and concentrations of the cleaning agents<br />

and disinfectants provided by the manufacturers.<br />

36 2010-03-17

6.6.2 Cleaning as needed<br />

Fig. 26<br />

Fig. 27<br />

Cleaning the rasping head and the rasping disk:<br />

Electric horse tooth rasp<br />

2010-03-17 37<br />

Use<br />

1. Remove the rasping disk from the rasping head as described<br />

in steps 1 through 5 of chapter "Changing the rasping disk"<br />

(page 39).<br />

2. Use a soft plastic brush to thoroughly clean the rasping head.<br />

3. Use the cleaning tip (2) of the fixing plate (1) to remove dirt<br />

from hard-to-reach areas such as the fixing holes (3).<br />

4. Use a soft plastic brush to thoroughly clean the rasping disk.<br />

5. Re-attach the rasping disk to the rasping head as described in<br />

steps 6 through 13 of chapter "Changing the rasping disk"<br />

(pages 39 and 40).

Electric horse tooth rasp<br />

Use<br />

6.7 Working on the machine<br />

6.7.1 Aligning the rasp attachment<br />

Fig. 28<br />

Fig. 29<br />

Fig. 30<br />

Fig. 31<br />

2<br />

2<br />

1<br />

1<br />

The rasp attachment can be rotated by 180° to ensure the grip<br />

can be held ergonomically at any stage of use.<br />

1. Use the Torx 25 (1) screwdriver to loosen the M5x16 (2)<br />

fillister head screw on the fitting. Do not unscrew it.<br />

2. Rotate the fitting and align the rasp attachment as needed.<br />

3. Make sure the fitting is flush with the power unit. If<br />

necessary, slide the fitting all the way against the power unit.<br />

4. Tighten the M5x16 (2) fillister head screw using a Torx 25<br />

screwdriver (1).<br />

38 2010-03-17

6.7.2 Changing the rasping disk<br />

Fig. 32<br />

Fig. 33<br />

Fig. 34<br />

1. Place the fixing plate (1) onto the rasping disk.<br />

Electric horse tooth rasp<br />

2010-03-17 39<br />

Use<br />

2. Make sure that the fixing pins (2) of the fixing plate are inside<br />

the fixing holes (3) on the rasping disk. If necessary, turn the<br />

rasping disk slightly until the fixing pins lock into place.<br />

3. Use one finger to press and hold the fixing plate on the<br />

rasping disk.<br />

4. Unscrew and remove the M5x8 countersunk screw using a<br />

Torx 25 screwdriver (1).<br />

5. Remove the rasping disk from the rasping head.<br />

6. Align the driving pins (1) of the rasping head with the bores<br />

(2) on the rasping disk.<br />

7. Place the rasping disk onto the rasping head.<br />

8. Make sure that both driving pins (1) are inside the bores (2)<br />

of the rasping disk. If necessary, turn the rasping disk slightly<br />

until the fixing pins lock into place.

Electric horse tooth rasp<br />

Use<br />

Fig. 35<br />

Fig. 36<br />

Fig. 37<br />

9. Insert the M5x8 countersunk screw into the bore on the<br />

rasping disk.<br />

10. Place the fixing plate (1) onto the rasping disk.<br />

11. Make sure that the fixing pins (2) are inside the fixing holes<br />

(3). If necessary, turn the rasping disk slightly until the fixing<br />

pins lock into place.<br />

12. Use one finger to press and hold the fixing plate on the<br />

rasping disk.<br />

13. Tighten the M5x8 countersunk screw using a Torx 25<br />

screwdriver (1).<br />

40 2010-03-17

7 Troubleshooting<br />

7.1 Safety<br />

Electric horse tooth rasp<br />

Troubleshooting<br />

The following chapter contains fault indications as well as possible<br />

causes of and steps to correct faults.<br />

Contact the manufacturer (see service address on page 2) in case<br />

the information provided below is not sufficient to correct the fault<br />

you are experiencing.<br />

Personnel � Unless specified otherwise, the troubleshooting steps described<br />

here can be performed by the operator.<br />

Electrical system<br />

� Some troubleshooting steps may only be performed by specially<br />

trained experts or the manufacturer. The description of each<br />

fault will specify the personnel requirements for correcting the<br />

fault.<br />

� Work on the electrical system may only be performed by<br />

trained electricians.<br />

DANGER!<br />

Danger of death due to electric current!<br />

Coming into contact with live components may<br />

result in death. Switched-on electrical components<br />

may move uncontrollably and cause severe injury.<br />

Therefore:<br />

– Before commencing work, switch off the power<br />

supply and prevent it from coming back on.<br />

2010-03-17 41

Electric horse tooth rasp<br />

Troubleshooting<br />

Improper troubleshooting<br />

Actions in the event of a fault Always:<br />

7.2 Troubleshooting table<br />

WARNING!<br />

Risk of injury due to improper<br />

troubleshooting!<br />

Improper troubleshooting may lead to serious<br />

injury to man and animal as well as property<br />

damage.<br />

Therefore:<br />

– Make sure there is enough mounting clearance<br />

before starting to work.<br />

– Keep the installation site tidy and clean!<br />

Components and tools lying loosely about or on<br />

top of each other may cause accidents.<br />

– If components have previously been removed,<br />

make sure they are re-installed correctly before<br />

re-attaching all fixing elements and tightening<br />

them to torque.<br />

1. Switch off the machine immediately in the event of faults that<br />

pose an immediate danger to man, animal or property.<br />

2. Find the cause of the fault.<br />

3. Depending on the kind of the fault, have an authorized expert<br />

correct the fault or correct the fault yourself.<br />

IMPORTANT!<br />

The troubleshooting table below specifies who is<br />

authorized to correct each individual fault.<br />

Fault Possible cause Troubleshooting Correction by<br />

Rasping disk stops rotating<br />

at low bearing pressure.<br />

Dark liquid leaks from the<br />

rasping head.<br />

Residual current circuit<br />

breaker does not work.<br />

Belt tension too low. Increase belt tension<br />

(see chapter 7.3.1).<br />

Sealing ring defective. Replace sealing ring<br />

(see chapter 7.3.2).<br />

Residual current circuit<br />

breaker defective.<br />

Replace residual<br />

current circuit breaker.<br />

Operator<br />

Operator<br />

Trained electrician/<br />

manufacturer<br />

42 2010-03-17

7.3 Troubleshooting steps<br />

7.3.1 Adjusting the belt tension (only when cold)<br />

Fig. 38<br />

Fig. 39<br />

Fig. 40<br />

Electric horse tooth rasp<br />

Troubleshooting<br />

If the rasping disk stops at low bearing pressures, increase the<br />

belt tension of the machine proceeding as follows:<br />

1. Loosen both M5x16 countersunk screws (1) by one turn using<br />

a Torx 25 (2) screwdriver. Do not unscrew the screws.<br />

2. Press the housing edge (1) of the fitting against a straight<br />

edge (2). The tube must lie flat on the plane.<br />

3. Pull the tube (1) forward to increase the belt tension.<br />

4. Retain the tension while tightening both M5x16 countersunk<br />

screws using the Torx 25 screwdriver.<br />

2010-03-17 43

Electric horse tooth rasp<br />

Troubleshooting<br />

7.3.2 Changing the sealing ring<br />

Fig. 41<br />

Fig. 42<br />

Fig. 43<br />

Fig. 44<br />

If you change the sealing yourself, you do so at your own risk as<br />

replacing the sealing ring may damage the rasp attachment.<br />

Consult the manufacturer if necessary (for the manufacturer's<br />

address, see page 2).<br />

1. Use a soft plastic brush to thoroughly clean the rasping head.<br />

2. Let the rasping head dry.<br />

3. Put the screwdriver to the outer diameter of the sealing ring.<br />

4. Use the screwdriver to lift the sealing ring out of its holder.<br />

5. Apply silicon spray to the new sealing ring and the rasping<br />

head.<br />

6. Use both thumbs to press the sealing ring into the holder of<br />

the rasping head.<br />

7. Make sure the sealing ring is placed flush in the holder.<br />

44 2010-03-17

7.4 Use after fault has been corrected<br />

Electric horse tooth rasp<br />

Troubleshooting<br />

After correcting the fault, start the machine as specified in chapter<br />

"Use."<br />

2010-03-17 45

Electric horse tooth rasp<br />

Disposal<br />

8 Disposal<br />

Unless a return and disposal agreement has been made, recycle<br />

disassembled components as follows:<br />

� Scrap metals.<br />

� Recycle plastic components.<br />

� Dispose of the remaining components in accordance with the<br />

material of which they are made.<br />

NOTICE!<br />

Damage to the environment due to incorrect<br />

disposal!<br />

Electronic scrap, electronic components, lubricants<br />

and other supplies must be treated as hazardous<br />

waste and disposed of only by certified expert<br />

companies!<br />

Consult your local authorities or specialized waste management<br />

companies for information on environmentally safe disposal.<br />

46 2010-03-17

9 Spare parts<br />

9.1 Spare part orders<br />

9.2 Spare parts list<br />

Fig. 45<br />

Item Item number Description<br />

When ordering spare parts,<br />

1 10956/66 Torx screwdriver (TX 25)<br />

2 10956/65 Fixing plate<br />

Electric horse tooth rasp<br />

Spare parts<br />

� include the serial number of the machine (see nameplate) and<br />

� the item number of the spare part.<br />

3 10956/21 Countersunk screw (TX 25) M5x8<br />

4 10956/15 Rasping disk HM (hard metal)<br />

2010-03-17 47

Electric horse tooth rasp<br />

Spare parts<br />

Item Item number Description<br />

4 10956/15D1 Rasping disk, diamond, curved<br />

4 10956/15D2 Rasping disk, diamond, flat<br />

4 10956/15CC1 Barolin-compliant rasping disk<br />

5 10956/17 Sealing ring<br />

6 10956/116 Bearing cover F3<br />

7 10956/101 Slide ring<br />

8 10956/113 Driving pins 3h9/2.5x8 offset<br />

9 10956/115 Pulley front F3<br />

10 10956/19 Miniature bearing (head)<br />

11 10956/50/EU Coupling piece/driver EU<br />

11 10956/50/USA Coupling piece/driver USA<br />

12 10956/118 Drive belt RB 3x1,200<br />

12 10956/119 Drive belt RB 3x965 (pony)<br />

13 10956/10484 Head and tube Slimline 1200<br />

13 10956/108 Head and tube Slimline 965 (pony)<br />

14 10956/61 Countersunk slotted screw M3x40<br />

15 10956/25 O-ring<br />

16/26 10956/106 Set of gears<br />

17 10956/63 Shim washer<br />

18 10956/23 Countersunk screw (TX 25) M5x16<br />

19 10956/109 O-ring housing (front piece)<br />

20 10956/62 Countersunk slotted screw M3x12<br />

21 10956/02 Cover with serial number<br />

22 10956/16 Miniature bearing (housing)<br />

23 10956/52 Ball bearing (housing)<br />

24 10956/60 Seeger ring<br />

48 2010-03-17

Item Item number Description<br />

25 10956/111 O-ring bevel wheel (bearing)<br />

27 10956/83 Buckle<br />

28 10956/117 Housing<br />

29 10956/24 Fillister head screw M5x16<br />

30 10956/110 O-ring housing (bearing)<br />

31 10956/54 Seeger ring<br />

10956/95 Power unit <strong>KRESS</strong> incl. 4m cable<br />

10956/97 Cable 4m to <strong>KRESS</strong> power unit<br />

10956/74 Residual current circuit breaker CH<br />

10956/75 Residual current circuit breaker Schuko<br />

10956/120 Set of sealings<br />

10956/SL Electric tooth rasp "swissfloat TM slimline" (1200)<br />

10956/SL-P Electric tooth rasp "swissfloat TM slimline" (965), model: Pony<br />

10957/SL<br />

Custom models: inquire about spare parts.<br />

Electric tooth rasp "swissfloat TM slimline", model: Short<br />

Electric horse tooth rasp<br />

Spare parts<br />

2010-03-17 49

Electric horse tooth rasp<br />

Appendix<br />

10 Appendix<br />

10.1.1 Declaration of Conformity<br />

Manufacturer:<br />

Declaration of Conformity<br />

as required by EC Machinery Directive M98/37/EC, Annex II A<br />

EISENHUT-VET <strong>AG</strong><br />

Sandweg 52<br />

CH-4123 Allschwil<br />

We hereby declare that the product specified below complies with the fundamental safety requirements<br />

of the Machinery Directive including all of its amendments applicable at the time this declaration is made<br />

based on the design, construction, and type of the product's model that is placed into circulation.<br />

Product description: Electric horse tooth rasp<br />

Type designation: swissfloat TM slimline<br />

Serial number: XXXX-F3<br />

Application EC<br />

directives:<br />

Applied<br />

harmonized<br />

standards:<br />

EC Machinery Directive 98/37/EC<br />

EC Low Voltage Directive 2006/95/EC<br />

EC Electromagnetic Compatibility Directive 2004/108/EC<br />

DIN EN ISO 12100-1/-2; Safety of machinery – basic concepts, general principles<br />

for design<br />

DIN EN 60204; Safety of machinery – electrical equipment of machines<br />

DIN EN 50081; DIN EN 50082; EMC generic standards<br />

Retrofitting or modifying the product in any way will void this declaration with immediate<br />

effect.<br />

Allschwil, June 19,<br />

2008<br />

50 2010-03-17

11 Index<br />

B<br />

Belt tension, adjust..........................................43<br />

Bleeding .........................................................32<br />

Brief description<br />

C<br />

entire machine.............................................20<br />

fitting ..........................................................22<br />

power unit...................................................21<br />

rasping head................................................21<br />

residual current circuit breaker......................22<br />

CE mark..........................................................50<br />

Cleaning<br />

after use......................................................36<br />

as needed ...................................................37<br />

Components....................................................21<br />

Connected loads..............................................18<br />

Contact............................................................ 9<br />

Copyright......................................................... 8<br />

Customer service.............................................. 9<br />

D<br />

Dangers..........................................................14<br />

Dental treatment..........................................32ff.<br />

canines........................................................35<br />

chewing surface...........................................35<br />

incisors........................................................35<br />

lower jaw ....................................................33<br />

upper jaw....................................................33<br />

Disposal..........................................................46<br />

E<br />

Electric current................................................14<br />

Emissions........................................................18<br />

Environmental protection .................................16<br />

Electric horse tooth rasp<br />

Index<br />

2010-03-17 51<br />

F<br />

Faults<br />

troubleshooting ........................................... 43<br />

Full mouth speculum ....................................... 31<br />

G<br />

General information<br />

I<br />

tooth rasp ................................................... 17<br />

tooth rasp pony ........................................... 17<br />

tooth rasp short........................................... 18<br />

Improper use.................................................. 12<br />

Initial operation .............................................. 26<br />

Intended use .................................................. 12<br />

L<br />

Liability.............................................................8<br />

Locking rotating speed .................................... 29<br />

Lubricants....................................................... 16<br />

M<br />

Machinery Directive......................................... 50<br />

N<br />

Nameplate...................................................... 19<br />

Noise........................................................ 14, 18<br />

O<br />

Operation ....................................................... 29<br />

Order ..........................................................47ff.<br />

Overheating.................................................... 32<br />

Overview<br />

entire machine ............................................ 20<br />

fitting.......................................................... 22<br />

power unit................................................... 21<br />

rasping head ............................................... 21<br />

residual current circuit breaker ..................... 22

P<br />

Electric horse tooth rasp<br />

Index<br />

Packaging ...................................................... 23<br />

Packaging materials ........................................ 24<br />

Personnel<br />

faults .......................................................... 41<br />

qualifications............................................... 11<br />

requirements............................................... 11<br />

Protective equipment ...................................... 13<br />

Q<br />

hearing protection ....................................... 13<br />

operation .................................................... 25<br />

protective gloves, microorganisms ................ 13<br />

safety goggles............................................. 13<br />

shoes, non-slip ............................................ 13<br />

Qualified personnel ......................................... 11<br />

R<br />

Rasp attachment, align ................................... 38<br />

Rasping disk ................................................... 15<br />

Rasping disk, change ...................................... 39<br />

Residual current circuit breaker<br />

function check............................................. 28<br />

mark........................................................... 27<br />

52 2010-03-17<br />

S<br />

Safety.............................................................10<br />

Service............................................................. 9<br />

Setup..............................................................20<br />

Spare parts ................................................. 47ff.<br />

Storage...........................................................24<br />

Surfaces, hot...................................................15<br />

Switching the machine off................................30<br />

Switching the machine on ................................29<br />

Symbols........................................................... 7<br />

T<br />

Technical Specifications .............................17, 18<br />

Trained electrician ...........................................11<br />

Transport........................................................23<br />

Transport inspection ........................................23<br />

Troubleshooting ..............................................41<br />

Troubleshooting table ......................................42<br />

U<br />

Use...........................................................12, 25<br />

User ...............................................................10<br />

W<br />

Work clothes, suitable......................................13