Installer's handbook - 1/3 Types of installation - 2/3 Software guide ...

Installer's handbook - 1/3 Types of installation - 2/3 Software guide ...

Installer's handbook - 1/3 Types of installation - 2/3 Software guide ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4.3 SEQUENT GENIUS.M<br />

REDUCER (CNG VERSION)<br />

In the CNG version the reducer,<br />

called SEQUENT GENIUS.M (picture<br />

7), consists <strong>of</strong> two reduction<br />

stages, which have the following<br />

operations:<br />

- to face every CNG pressure<br />

level coming from the tank (load<br />

pressure around 22 MPa corresponding<br />

to 220 bar),<br />

- to spread the CNG at the intermediate<br />

pressure, <strong>of</strong> 500 - 600 kPa<br />

(5 - 6 bar) in a first stage,<br />

- to bring the heat necessary to<br />

avoid an excessive cooling <strong>of</strong> fuel<br />

due to a sudden expansion,<br />

- to spread the CNG further on<br />

at the requested pressure, <strong>of</strong> 200<br />

kPa (2 bar), useful to supply the<br />

injection system. Such a value <strong>of</strong><br />

outlet pressure is conditioned by<br />

the pressure signal <strong>of</strong> the air intake<br />

manifold: in practice, the differential<br />

pressure is kept constant between<br />

the CNG pipe at the outlet <strong>of</strong> the<br />

reducer and the air-intake manifold.<br />

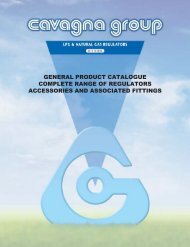

As can be seen from picture 8,<br />

the second stage <strong>of</strong> the SEQUENT<br />

GENIUS.M CNG reducer is very<br />

similar to the first and only stage <strong>of</strong><br />

the SEQUENT GENIUS LPG reducer<br />

version.<br />

Despite the particular compact<br />

dimensions, the reducer guarantees<br />

high gas flows, in order to satisfy<br />

powers up to 140 kW (190CV).<br />

4.4 ZENITH REDUCER<br />

(CNG VERSION)<br />

This is the new reducer for CNG<br />

<strong>installation</strong> and for Sequent<br />

Fastness system only and has<br />

important innovation and improvement.<br />

The reducer consists <strong>of</strong> two<br />

reduction stages with the following<br />

aim:<br />

- to face every CNG pressure<br />

level coming from the tank (load<br />

pressure around 22 MPa corre-<br />

TEMPERATURE SENSOR<br />

FEEDBACK<br />

WATER<br />

GAS INLET<br />

2 ND STAGE<br />

1 ST STAGE<br />

sponding to 220 bar),<br />

- to spread the CNG at the intermediate<br />

pressure, <strong>of</strong> 500 - 600 kPa<br />

(5 - 6 bar) in a first stage,<br />

- to bring the heat necessary to<br />

avoid an excessive cooling <strong>of</strong> fuel<br />

due to a sudden expansion,<br />

15<br />

Picture 07<br />

Sequent M.<br />

Genius Reducer<br />

Picture 08<br />

Sequent M. Genius<br />

Reducer - Sectional<br />

view -<br />

Picture 09<br />

Temperature sensor<br />

- to spread the CNG further on<br />

at the requested pressure, <strong>of</strong> 200<br />

kPa (2 bar), useful to supply the<br />

injection system. Such a value <strong>of</strong><br />

outlet pressure is conditioned by<br />

the pressure signal <strong>of</strong> the air intake<br />

manifold: in practice, the differential