KESSEL-Kleinkläranlagen InnoClean PLUS

KESSEL-Kleinkläranlagen InnoClean PLUS

KESSEL-Kleinkläranlagen InnoClean PLUS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

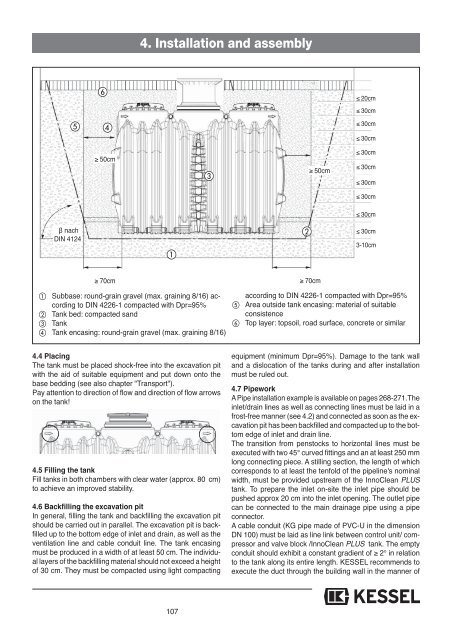

β nach<br />

DIN 4124<br />

<br />

<br />

≥ 50cm<br />

4.4 Placing<br />

The tank must be placed shock-free into the excavation pit<br />

with the aid of suitable equipment and put down onto the<br />

base bedding (see also chapter "Transport").<br />

Pay attention to direction of flow and direction of flow arrows<br />

on the tank!<br />

4.5 Filling the tank<br />

Fill tanks in both chambers with clear water (approx. 80 cm)<br />

to achieve an improved stability.<br />

4.6 Backfilling the excavation pit<br />

In general, filling the tank and backfilling the excavation pit<br />

should be carried out in parallel. The excavation pit is backfilled<br />

up to the bottom edge of inlet and drain, as well as the<br />

ventilation line and cable conduit line. The tank encasing<br />

must be produced in a width of at least 50 cm. The individual<br />

layers of the backfilling material should not exceed a height<br />

of 30 cm. They must be compacted using light compacting<br />

4. Installation and assembly<br />

<br />

Subbase: round-grain gravel (max. graining 8/16) according<br />

to DIN 4226-1 compacted with Dpr=95%<br />

Tank bed: compacted sand<br />

Tank<br />

Tank encasing: round-grain gravel (max. graining 8/16)<br />

107<br />

<br />

≥ 50cm<br />

≥ 70cm ≥ 70cm<br />

<br />

≤ 20cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

≤ 30cm<br />

3-10cm<br />

according to DIN 4226-1 compacted with Dpr=95%<br />

Area outside tank encasing: material of suitable<br />

consistence<br />

Top layer: topsoil, road surface, concrete or similar<br />

equipment (minimum Dpr=95%). Damage to the tank wall<br />

and a dislocation of the tanks during and after installation<br />

must be ruled out.<br />

4.7 Pipework<br />

A Pipe installation example is available on pages 268-271.The<br />

inlet/drain lines as well as connecting lines must be laid in a<br />

frost-free manner (see 4.2) and connected as soon as the excavation<br />

pit has been backfilled and compacted up to the bottom<br />

edge of inlet and drain line.<br />

The transition from penstocks to horizontal lines must be<br />

executed with two 45° curved fittings and an at least 250 mm<br />

long connecting piece. A stilling section, the length of which<br />

corresponds to at least the tenfold of the pipeline's nominal<br />

width, must be provided upstream of the <strong>InnoClean</strong> <strong>PLUS</strong><br />

tank. To prepare the inlet on-site the inlet pipe should be<br />

pushed approx 20 cm into the inlet opening. The outlet pipe<br />

can be connected to the main drainage pipe using a pipe<br />

connector.<br />

A cable conduit (KG pipe made of PVC-U in the dimension<br />

DN 100) must be laid as line link between control unit/ compressor<br />

and valve block /<strong>InnoClean</strong> <strong>PLUS</strong> tank. The empty<br />

conduit should exhibit a constant gradient of ≥ 2° in relation<br />

to the tank along its entire length. <strong>KESSEL</strong> recommends to<br />

execute the duct through the building wall in the manner of