KESSEL-Kleinkläranlagen InnoClean PLUS

KESSEL-Kleinkläranlagen InnoClean PLUS

KESSEL-Kleinkläranlagen InnoClean PLUS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

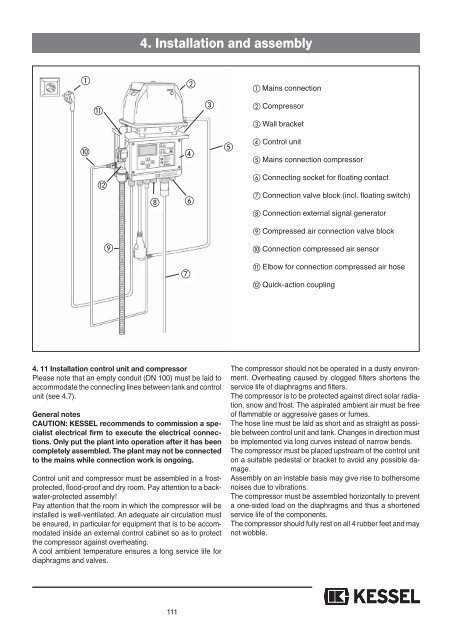

4. 11 Installation control unit and compressor<br />

Please note that an empty conduit (DN 100) must be laid to<br />

accommodate the connecting lines between tank and control<br />

unit (see 4.7).<br />

General notes<br />

CAUTION: <strong>KESSEL</strong> recommends to commission a specialist<br />

electrical firm to execute the electrical connections.<br />

Only put the plant into operation after it has been<br />

completely assembled. The plant may not be connected<br />

to the mains while connection work is ongoing.<br />

Control unit and compressor must be assembled in a frostprotected,<br />

flood-proof and dry room. Pay attention to a backwater-protected<br />

assembly!<br />

Pay attention that the room in which the compressor will be<br />

installed is well-ventilated. An adequate air circulation must<br />

be ensured, in particular for equipment that is to be accommodated<br />

inside an external control cabinet so as to protect<br />

the compressor against overheating.<br />

A cool ambient temperature ensures a long service life for<br />

diaphragms and valves.<br />

4. Installation and assembly<br />

<br />

111<br />

<br />

<br />

<br />

<br />

<br />

Mains connection<br />

Compressor<br />

Wall bracket<br />

Control unit<br />

Mains connection compressor<br />

Connecting socket for floating contact<br />

Connection valve block (incl. floating switch)<br />

Connection external signal generator<br />

Compressed air connection valve block<br />

Connection compressed air sensor<br />

Elbow for connection compressed air hose<br />

Quick-action coupling<br />

The compressor should not be operated in a dusty environment.<br />

Overheating caused by clogged filters shortens the<br />

service life of diaphragms and filters.<br />

The compressor is to be protected against direct solar radiation,<br />

snow and frost. The aspirated ambient air must be free<br />

of flammable or aggressive gases or fumes.<br />

The hose line must be laid as short and as straight as possible<br />

between control unit and tank. Changes in direction must<br />

be implemented via long curves instead of narrow bends.<br />

The compressor must be placed upstream of the control unit<br />

on a suitable pedestal or bracket to avoid any possible damage.<br />

Assembly on an instable basis may give rise to bothersome<br />

noises due to vibrations.<br />

The compressor must be assembled horizontally to prevent<br />

a one-sided load on the diaphragms and thus a shortened<br />

service life of the components.<br />

The compressor should fully rest on all 4 rubber feet and may<br />

not wobble.