Tischkreissäge Table Saw Scie circulaire sur ... - Nářadí PEDDY.cz

Tischkreissäge Table Saw Scie circulaire sur ... - Nářadí PEDDY.cz

Tischkreissäge Table Saw Scie circulaire sur ... - Nářadí PEDDY.cz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

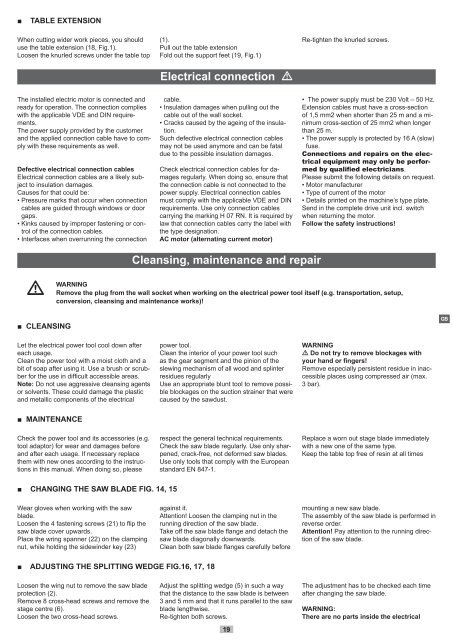

■TABLE EXTENSIONWhen cutting wider work pieces, you shoulduse the table extension (18, Fig.1).Loosen the knurled screws under the table top(1).Pull out the table extensionFold out the support feet (19, Fig.1)Electrical connection mRe-tighten the knurled screws.The installed electric motor is connected andready for operation. The connection complieswith the applicable VDE and DIN requirements.The power supply provided by the customerand the applied connection cable have to complywith these requirements as well.Defective electrical connection cablesElectrical connection cables are a likely subjectto insulation damages.Causes for that could be:• Pres<strong>sur</strong>e marks that occur when connectioncables are guided through windows or doorgaps.• Kinks caused by improper fastening or controlof the connection cables.• Interfaces when overrunning the connectioncable.• Insulation damages when pulling out thecable out of the wall socket.• Cracks caused by the ageing of the insulation.Such defective electrical connection cablesmay not be used anymore and can be fataldue to the possible insulation damages.Check electrical connection cables for damagesregularly. When doing so, en<strong>sur</strong>e thatthe connection cable is not connected to thepower supply. Electrical connection cablesmust comply with the applicable VDE and DINrequirements. Use only connection cablescarrying the marking H 07 RN. It is required bylaw that connection cables carry the label withthe type designation.AC motor (alternating current motor)• The power supply must be 230 Volt – 50 Hz.Extension cables must have a cross-sectionof 1,5 mm2 when shorter than 25 m and a minimumcross-section of 25 mm2 when longerthan 25 m.• The power supply is protected by 16 A (slow)fuse.Connections and repairs on the electricalequipment may only be performedby qualified electricians.Please submit the following details on request.• Motor manufacturer• Type of current of the motor• Details printed on the machine’s type plate.Send in the complete drive unit incl. switchwhen returning the motor.Follow the safety instructions!Cleansing, maintenance and repairm WARNINGRemove the plug from the wall socket when working on the electrical power tool itself (e.g. transportation, setup,conversion, cleansing and maintenance works)!■ CLEANSINGGBLet the electrical power tool cool down aftereach usage.Clean the power tool with a moist cloth and abit of soap after using it. Use a brush or scrubberfor the use in difficult accessible areas.Note: Do not use aggressive cleansing agentsor solvents. These could damage the plasticand metallic components of the electricalpower tool.Clean the interior of your power tool suchas the gear segment and the pinion of theslewing mechanism of all wood and splinterresidues regularlyUse an appropriate blunt tool to remove possibleblockages on the suction strainer that werecaused by the sawdust.WARNINGm Do not try to remove blockages withyour hand or fingers!Remove especially persistent residue in inaccessibleplaces using compressed air (max.3 bar).■ MAINTENANCECheck the power tool and its accessories (e.g.tool adaptor) for wear and damages beforeand after each usage. If necessary replacethem with new ones according to the instructionsin this manual. When doing so, pleaserespect the general technical requirements.Check the saw blade regularly. Use only sharpened,crack-free, not deformed saw blades.Use only tools that comply with the Europeanstandard EN 847-1.Replace a worn out stage blade immediatelywith a new one of the same type.Keep the table top free of resin at all times■ CHANGING THE SAW BLADE FIG. 14, 15Wear gloves when working with the sawblade.Loosen the 4 fastening screws (21) to flip thesaw blade cover upwards.Place the wring spanner (22) on the clampingnut, while holding the sidewinder key (23)against it.Attention! Loosen the clamping nut in therunning direction of the saw blade.Take off the saw blade flange and detach thesaw blade diagonally downwards.Clean both saw blade flanges carefully beforemounting a new saw blade.The assembly of the saw blade is performed inreverse order.Attention! Pay attention to the running directionof the saw blade.■ ADJUSTING THE SPLITTING WEDGE FIG.16, 17, 18Loosen the wing nut to remove the saw bladeprotection (2).Remove 8 cross-head screws and remove thestage centre (6).Loosen the two cross-head screws.Adjust the splitting wedge (5) in such a waythat the distance to the saw blade is between3 and 5 mm and that it runs parallel to the sawblade lengthwise.Re-tighten both screws.19The adjustment has to be checked each timeafter changing the saw blade.WARNING:There are no parts inside the electrical