Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

P R I N C I P A L<br />

melhorias de operação, que por sua vez lhe conferem<br />

como consequência maior flexibilidade operacional e<br />

aumento de vida útil.<br />

O gerente de engenharia Moacir Junges ressalta<br />

que as atualizações não ficam apenas para equipamentos<br />

novos, mas podem ser feitas em instalações<br />

já executadas. Equipamentos que se encontram em<br />

operação podem ser avaliados para receberem modernizações,<br />

gerando aumento de eficiência, redução<br />

de custo operacional e até por aumento da capacidade<br />

original.<br />

PROJETOS ESPECÍFICOS<br />

A H. Bremer trabalha com projetos padrões, personalizando<br />

cada caldeira ou aquecedor de acordo<br />

com a necessidade de cada cliente. As personalizações<br />

são feitas dentro de limites técnicos predeterminados,<br />

se adequando ao que será melhor para o<br />

As personalizações são feitas<br />

dentro de limites técnicos<br />

predeterminados, se adequando<br />

ao que será melhor para o cliente<br />

e ao que a H. Bremer pode<br />

oferecer<br />

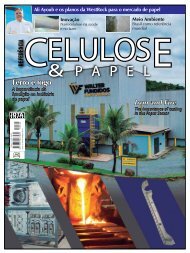

PARQUE FABRIL H. BREMER<br />

states Engineering Manager Junges. He also points out that<br />

after all of the Company’s projects go online, they can receive<br />

updates if opportunities for improvement are perceived.<br />

When the Company’s team perceives new opportunities<br />

due to changes such as fuels or working conditions, updates<br />

are applied to the new and existing facilities according to<br />

customer wishes. “These innovations are always implemented<br />

with parameters that guarantee constructive, efficiency,<br />

and operating improvements that give the boiler greater<br />

operational flexibility and increased service life.<br />

The Engineering Manager points out that the upgrades<br />

are not only for new equipment but can be performed on<br />

already installed equipment. Equipment that is in operation<br />

can be evaluated to receive updates, generating increased<br />

efficiency, reduction of operating costs, and even increased<br />

original capacity.<br />

SPECIFIC DESIGNS<br />

H. Bremer works with standard designs customizing<br />

each boiler or heater to the needs of each customer. Customizations<br />

are made within predetermined technical limits,<br />

according to what will be best for the customer and what<br />

H. Bremer can offer. “We consider the type of biomass,<br />

different fuel mixtures, pressure conditions, condensation,<br />

steam temperature, and installation layout according to the<br />

available space,” the Engineering Manager states.<br />

36<br />

CUTTING-EDGE LEADERSHIP<br />

Lilian Bremer Vogelbacher, Managing Director of H. Bremer<br />

and daughter of Horst Bremmer, who had been head<br />

of the Company for over fifty years, understands every detail<br />

of the procedures and continuously seeks to improve<br />

the Company’s quality standards. “We have a legacy, from<br />

our father, Horst Bremer, which guides us and we consider<br />

very precious - the love of the family, the respect for others,<br />

persistence, and, especially, working with the strong foundation<br />

of a company with a symbol of trust,” she says.