Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

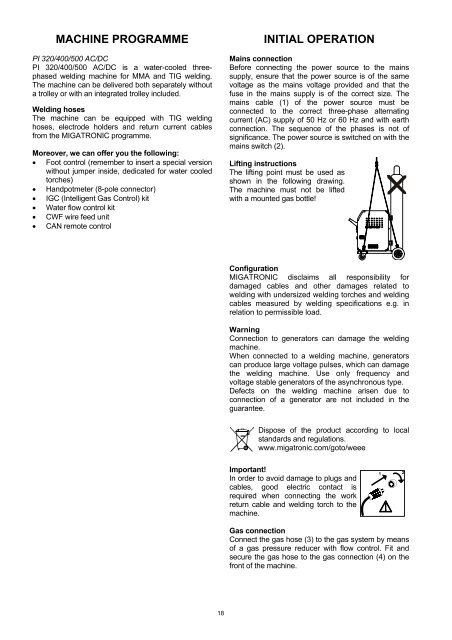

M<strong>AC</strong>HINE PROGRAMME<strong>PI</strong> <strong>320</strong>/<strong>400</strong>/<strong>500</strong> <strong>AC</strong>/<strong>DC</strong><strong>PI</strong> <strong>320</strong>/<strong>400</strong>/<strong>500</strong> <strong>AC</strong>/<strong>DC</strong> is a water-cooled threephasedwelding machine for MMA and TIG welding.The machine can be delivered both separately withouta trolley or with an integrated trolley included.Welding hosesThe machine can be equipped with TIG weldinghoses, electrode holders and return current cablesfrom the MIGATRONIC programme.Moreover, we can offer you the following:• Foot control (remember to insert a special versionwithout jumper inside, dedicated for water cooledtorches)• Handpotmeter (8-pole connector)• IGC (Intelligent Gas Control) kit• Water flow control kit• CWF wire feed unit• CAN remote controlINITIAL OPERATIONMains connectionBefore connecting the power source to the mainssupply, ensure that the power source is of the samevoltage as the mains voltage provided and that thefuse in the mains supply is of the correct size. Themains cable (1) of the power source must beconnected to the correct three-phase alternatingcurrent (<strong>AC</strong>) supply of 50 Hz or 60 Hz and with earthconnection. The sequence of the phases is not ofsignificance. The power source is switched on with themains switch (2).Lifting instructionsThe lifting point must be used asshown in the following drawing.The machine must not be liftedwith a mounted gas bottle!ConfigurationMIGATRONIC disclaims all responsibility fordamaged cables and other damages related towelding with undersized welding torches and weldingcables measured by welding specifications e.g. inrelation to permissible load.WarningConnection to generators can damage the weldingmachine.When connected to a welding machine, generatorscan produce large voltage pulses, which can damagethe welding machine. Use only frequency andvoltage stable generators of the asynchronous type.Defects on the welding machine arisen due toconnection of a generator are not included in theguarantee.Dispose of the product according to localstandards and regulations.www.migatronic.com/goto/weeeImportant!In order to avoid damage to plugs andcables, good electric contact isrequired when connecting the workreturn cable and welding torch to themachine.Gas connectionConnect the gas hose (3) to the gas system by meansof a gas pressure reducer with flow control. Fit andsecure the gas hose to the gas connection (4) on thefront of the machine.18