Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

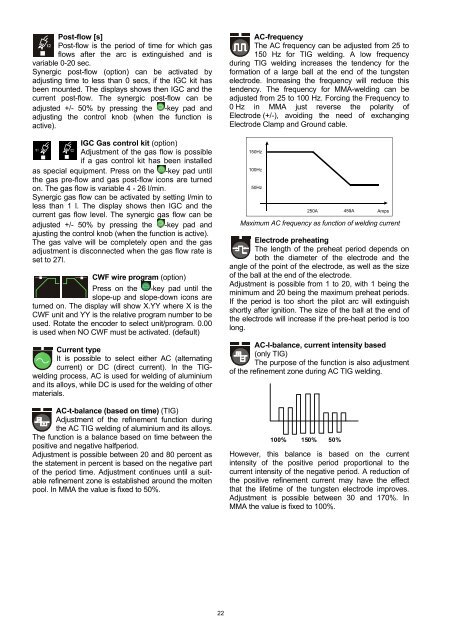

Post-flow [s]Post-flow is the period of time for which gasflows after the arc is extinguished and isvariable 0-20 sec.Synergic post-flow (option) can be activated byadjusting time to less than 0 secs, if the IGC kit hasbeen mounted. The displays shows then IGC and thecurrent post-flow. The synergic post-flow can beadjusted +/- 50% by pressing the -key pad andadjusting the control knob (when the function isactive).IGC Gas control kit (option)Adjustment of the gas flow is possibleif a gas control kit has been installedas special equipment. Press on the -key pad untilthe gas pre-flow and gas post-flow icons are turnedon. The gas flow is variable 4 - 26 l/min.Synergic gas flow can be activated by setting l/min toless than 1 l. The display shows then IGC and thecurrent gas flow level. The synergic gas flow can beadjusted +/- 50% by pressing the -key pad andajusting the control knob (when the function is active).The gas valve will be completely open and the gasadjustment is disconnected when the gas flow rate isset to 27l.CWF wire program (option)Press on the -key pad until theslope-up and slope-down icons areturned on. The display will show X.YY where X is theCWF unit and YY is the relative program number to beused. Rotate the encoder to select unit/program. 0.00is used when NO CWF must be activated. (default)Current typeIt is possible to select either <strong>AC</strong> (alternatingcurrent) or <strong>DC</strong> (direct current). In the TIGweldingprocess, <strong>AC</strong> is used for welding of aluminiumand its alloys, while <strong>DC</strong> is used for the welding of othermaterials.<strong>AC</strong>-t-balance (based on time) (TIG)Adjustment of the refinement function duringthe <strong>AC</strong> TIG welding of aluminium and its alloys.The function is a balance based on time between thepositive and negative halfperiod.Adjustment is possible between 20 and 80 percent asthe statement in percent is based on the negative partof the period time. Adjustment continues until a suitablerefinement zone is established around the moltenpool. In MMA the value is fixed to 50%.<strong>AC</strong>-frequencyThe <strong>AC</strong> frequency can be adjusted from 25 to150 Hz for TIG welding. A low frequencyduring TIG welding increases the tendency for theformation of a large ball at the end of the tungstenelectrode. Increasing the frequency will reduce thistendency. The frequency for MMA-welding can beadjusted from 25 to 100 Hz. Forcing the Frequency to0 Hz in MMA just reverse the polarity ofElectrode (+/-), avoiding the need of exchangingElectrode Clamp and Ground cable.Maximum <strong>AC</strong> frequency as function of welding currentElectrode preheatingThe length of the preheat period depends onboth the diameter of the electrode and theangle of the point of the electrode, as well as the sizeof the ball at the end of the electrode.Adjustment is possible from 1 to 20, with 1 being theminimum and 20 being the maximum preheat periods.If the period is too short the pilot arc will extinguishshortly after ignition. The size of the ball at the end ofthe electrode will increase if the pre-heat period is toolong.<strong>AC</strong>-I-balance, current intensity based(only TIG)The purpose of the function is also adjustmentof the refinement zone during <strong>AC</strong> TIG welding.100% 150% 50%However, this balance is based on the currentintensity of the positive period proportional to thecurrent intensity of the negative period. A reduction ofthe positive refinement current may have the effectthat the lifetime of the tungsten electrode improves.Adjustment is possible between 30 and 170%. InMMA the value is fixed to 100%.22