Jahresbericht 2009 - Biba - Universität Bremen

Jahresbericht 2009 - Biba - Universität Bremen

Jahresbericht 2009 - Biba - Universität Bremen

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

Collaborative Research Centre 570<br />

Distortion Engineering<br />

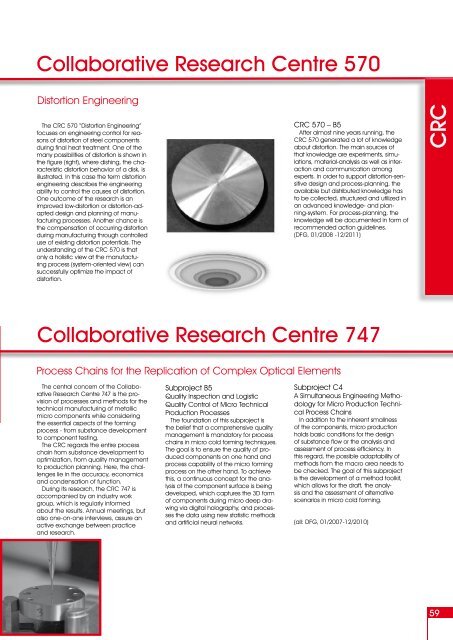

The CRC 570 “Distortion Engineering”<br />

focuses on engineering control for reasons<br />

of distortion of steel components<br />

during final heat treatment. One of the<br />

many possibilities of distortion is shown in<br />

the figure (right), where dishing, the characteristic<br />

distortion behavior of a disk, is<br />

illustrated. In this case the term distortion<br />

engineering describes the engineering<br />

ability to control the causes of distortion.<br />

One outcome of the research is an<br />

improved low-distortion or distortion-adapted<br />

design and planning of manufacturing<br />

processes. Another chance is<br />

the compensation of occurring distortion<br />

during manufacturing through controlled<br />

use of existing distortion potentials. The<br />

understanding of the CRC 570 is that<br />

only a holistic view at the manufacturing<br />

process (system-oriented view) can<br />

successfully optimize the impact of<br />

distortion.<br />

Collaborative Research Centre 747<br />

Process Chains for the Replication of Complex Optical Elements<br />

The central concern of the Collaborative<br />

Research Centre 747 is the provision<br />

of processes and methods for the<br />

technical manufacturing of metallic<br />

micro components while considering<br />

the essential aspects of the forming<br />

process - from substance development<br />

to component testing.<br />

The CRC regards the entire process<br />

chain from substance development to<br />

optimization, from quality management<br />

to production planning. Here, the challenges<br />

lie in the accuracy, economics<br />

and condensation of function.<br />

During its research, the CRC 747 is<br />

accompanied by an industry work<br />

group, which is regularly informed<br />

about the results. Annual meetings, but<br />

also one-on-one interviews, assure an<br />

active exchange between practice<br />

and research.<br />

Subproject B5<br />

Quality Inspection and Logistic<br />

Quality Control of Micro Technical<br />

Production Processes<br />

The foundation of this subproject is<br />

the belief that a comprehensive quality<br />

management is mandatory for process<br />

chains in micro cold forming techniques.<br />

The goal is to ensure the quality of produced<br />

components on one hand and<br />

process capability of the micro forming<br />

process on the other hand. To achieve<br />

this, a continuous concept for the analysis<br />

of the component surface is being<br />

developed, which captures the 3D form<br />

of components during micro deep drawing<br />

via digital holography, and processes<br />

the data using new statistic methods<br />

and artificial neural networks.<br />

CRC 570 – B5<br />

After almost nine years running, the<br />

CRC 570 generated a lot of knowledge<br />

about distortion. The main sources of<br />

that knowledge are experiments, simulations,<br />

material-analysis as well as interaction<br />

and communication among<br />

experts. In order to support distortion-sensitive<br />

design and process-planning, the<br />

available but distributed knowledge has<br />

to be collected, structured and utilized in<br />

an advanced knowledge- and planning-system.<br />

For process-planning, the<br />

knowledge will be documented in form of<br />

recommended action guidelines.<br />

(DFG, 01/2008 -12/2011)<br />

Subproject C4<br />

A Simultaneous Engineering Methodology<br />

for Micro Production Technical<br />

Process Chains<br />

In addition to the inherent smallness<br />

of the components, micro production<br />

holds basic conditions for the design<br />

of substance flow or the analysis and<br />

assessment of process efficiency. In<br />

this regard, the possible adaptability of<br />

methods from the macro area needs to<br />

be checked. The goal of this subproject<br />

is the development of a method toolkit,<br />

which allows for the draft, the analysis<br />

and the assessment of alternative<br />

scenarios in micro cold forming.<br />

(all: DFG, 01/2007-12/2010)<br />

CRC<br />

59