Untitled - Future Pipe Industries

Untitled - Future Pipe Industries

Untitled - Future Pipe Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

7.6: Final pressure test<br />

After all backfilling has been completed and the entire pipeline construction has been completed (except at the closing ends<br />

or tie-in joints of the pipeline), the line shall be subjected to a final pressure test following the same basic procedures described<br />

in section 7.5. The final test pressure is generally equal to 1.25 times the intended working pressure of the pipeline (unless<br />

otherwise specifi ed by the Engineer). The duration of this test shall not be less than two hours, or the time to determine by<br />

visual inspection the closure joints and the overall soundness of the entire pipeline, whichever is greater.<br />

7.7: Testing according to method type 2 (using a joint tester)<br />

Field testing using method type 2 is applicable only for diameters of 36” and above. This method is recommended in the<br />

case of:<br />

• Non availability of a suitable water supply source<br />

• Unstable soils, which pose a potential problem in the case of use of test method 1<br />

• Very Large diameter pipelines where traditional pipe section pressure test is not feasible<br />

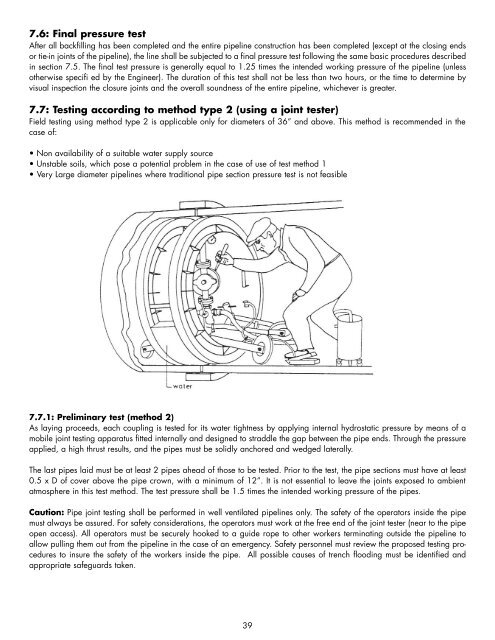

7.7.1: Preliminary test (method 2)<br />

As laying proceeds, each coupling is tested for its water tightness by applying internal hydrostatic pressure by means of a<br />

mobile joint testing apparatus fitted internally and designed to straddle the gap between the pipe ends. Through the pressure<br />

applied, a high thrust results, and the pipes must be solidly anchored and wedged laterally.<br />

The last pipes laid must be at least 2 pipes ahead of those to be tested. Prior to the test, the pipe sections must have at least<br />

0.5 x D of cover above the pipe crown, with a minimum of 12”. It is not essential to leave the joints exposed to ambient<br />

atmosphere in this test method. The test pressure shall be 1.5 times the intended working pressure of the pipes.<br />

Caution: <strong>Pipe</strong> joint testing shall be performed in well ventilated pipelines only. The safety of the operators inside the pipe<br />

must always be assured. For safety considerations, the operators must work at the free end of the joint tester (near to the pipe<br />

open access). All operators must be securely hooked to a guide rope to other workers terminating outside the pipeline to<br />

allow pulling them out from the pipeline in the case of an emergency. Safety personnel must review the proposed testing procedures<br />

to insure the safety of the workers inside the pipe. All possible causes of trench flooding must be identified and<br />

appropriate safeguards taken.<br />

39