Untitled - Future Pipe Industries

Untitled - Future Pipe Industries

Untitled - Future Pipe Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

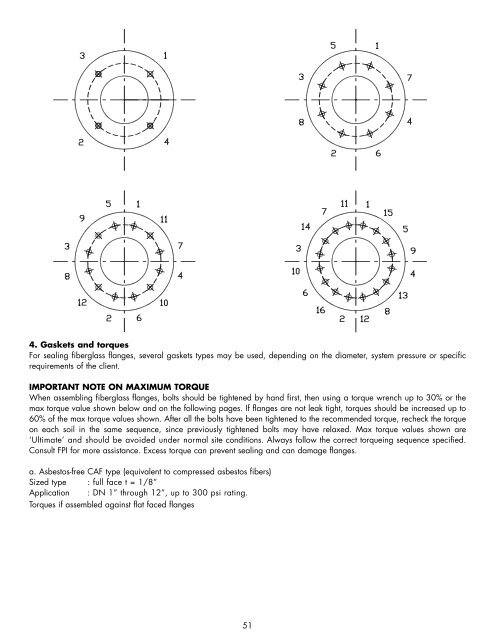

4. Gaskets and torques<br />

For sealing fiberglass flanges, several gaskets types may be used, depending on the diameter, system pressure or specific<br />

requirements of the client.<br />

IMPORTANT NOTE ON MAXIMUM TORQUE<br />

When assembling fiberglass flanges, bolts should be tightened by hand first, then using a torque wrench up to 30% or the<br />

max torque value shown below and on the following pages. If flanges are not leak tight, torques should be increased up to<br />

60% of the max torque values shown. After all the bolts have been tightened to the recommended torque, recheck the torque<br />

on each soil in the same sequence, since previously tightened bolts may have relaxed. Max torque values shown are<br />

‘Ultimate’ and should be avoided under normal site conditions. Always follow the correct torqueing sequence specified.<br />

Consult FPI for more assistance. Excess torque can prevent sealing and can damage flanges.<br />

a. Asbestos-free CAF type (equivalent to compressed asbestos fibers)<br />

Sized type : full face t = 1/8”<br />

Application : DN 1” through 12”, up to 300 psi rating.<br />

Torques if assembled against flat faced flanges<br />

51