Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

Heterogeneously Catalyzed Oxidation Reactions Using ... - CHEC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

egeneration by reduction<br />

surface cleaning<br />

high toluene selectivity<br />

limited by oxygen availabilty<br />

CHAPTER 5<br />

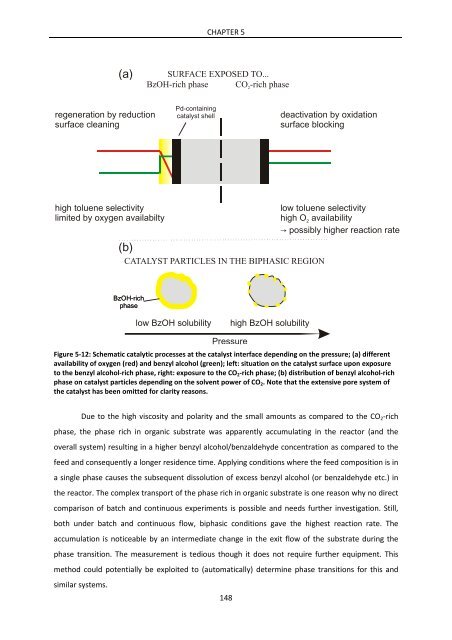

Figure 5‐12: Schematic catalytic processes at the catalyst interface depending on the pressure; (a) different<br />

availability of oxygen (red) and benzyl alcohol (green); left: situation on the catalyst surface upon exposure<br />

to the benzyl alcohol‐rich phase, right: exposure to the CO2‐rich phase; (b) distribution of benzyl alcohol‐rich<br />

phase on catalyst particles depending on the solvent power of CO2. Note that the extensive pore system of<br />

the catalyst has been omitted for clarity reasons.<br />

Due to the high viscosity and polarity and the small amounts as compared to the CO2‐rich<br />

phase, the phase rich in organic substrate was apparently accumulating in the reactor (and the<br />

overall system) resulting in a higher benzyl alcohol/benzaldehyde concentration as compared to the<br />

feed and consequently a longer residence time. Applying conditions where the feed composition is in<br />

a single phase causes the subsequent dissolution of excess benzyl alcohol (or benzaldehyde etc.) in<br />

the reactor. The complex transport of the phase rich in organic substrate is one reason why no direct<br />

comparison of batch and continuous experiments is possible and needs further investigation. Still,<br />

both under batch and continuous flow, biphasic conditions gave the highest reaction rate. The<br />

accumulation is noticeable by an intermediate change in the exit flow of the substrate during the<br />

phase transition. The measurement is tedious though it does not require further equipment. This<br />

method could potentially be exploited to (automatically) determine phase transitions for this and<br />

similar systems.<br />

(a)<br />

(b)<br />

SURFACE EXPOSED TO...<br />

BzOH-rich phase CO2-rich phase<br />

CATALYST PARTICLES IN THE BIPHASIC REGION<br />

BzOH-rich<br />

phase<br />

Pd-containing<br />

catalyst shell<br />

low BzOH solubility high BzOH solubility<br />

Pressure<br />

148<br />

deactivation by oxidation<br />

surface blocking<br />

low toluene selectivity<br />

high O 2 availability<br />

→ possibly higher reaction rate